Events

Revolutionizing Garment Quality: Key Questions Unveiled

News 2025-07-14 300

Friends, you absolutely need garment testing equipment in the textile industry. It's a must-have for evaluating fabrics and product's durability and performance. So, no matter if you're a seasoned clothing maker or just beginning, leveraging with these testing equipment is a significant matter. Alright, let's dive into some of the biggest questions about all that high-tech garment testing equipment.

What are the most commonly used garment testing machines?

How can garment testing equipment improve product quality?

What are the challenges in maintaining garment testing equipment?

How can manufacturers stay updated with the latest advancements in garment testing technology?

What are the future trends in garment testing technology?

What are the most commonly used garment testing machines?

In the realm of garment testing, several machines stand out for their versatility and reliability. Take the tensile property testing machine, for example. It's a pretty basic tool for figuring out how tough that cloth is.

It's all about measuring the force required to tear it takes to rip the material. And then there's the pilling resistance tester, checking out how prone that fabric is to those pesky bobbles, you know, those fluffy bits that can adversely affect look and longevity. You cannot be overlooked the seam durability tester, either. It makes sure those seams is resilient against harsh treatment without busting open.

How can garment testing equipment improve product quality?

It's not just about finding defects; it's mainly about making sure the whole product is top-notch. With these devices, makers can catch and fix issues at the start, which saves a ton of efficiency and resources.

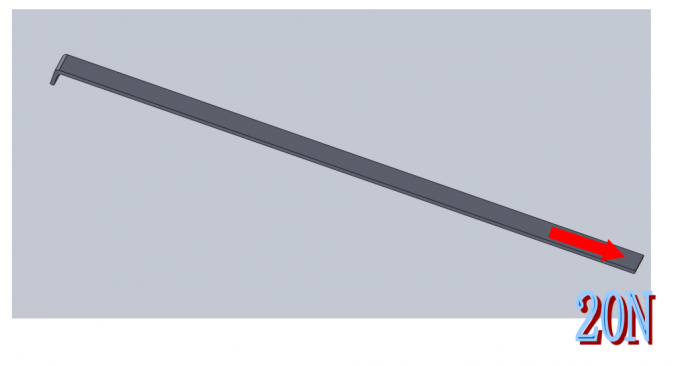

For instance, the dye fastness analyzer is key to keeping those fibers looking vivid and attractive, so no fading or bleeding, ya know? The tug strength tester helps in ensuring that the garments are durable and can withstand heavy usage.

What are the challenges in maintaining garment testing equipment?

Keeping that gear up and running can be tricky, especially since these things are usually pretty finicky. You need to stay on top of the periodic adjustment and maintenance of these machines to make sure they're giving you accurate results.

Also, these machines need additional care, like using correct cleaning materials and equipment. Neglecting maintenance? That's a bad move, as it can ruin your outcomes and damage your company's reputation.

How can manufacturers stay updated with the latest advancements in garment testing technology?

Keeping up with all the neat new stuff in garment testing tech is extremely important if you want to keep up with the big dogs. You do that by going to trade shows, reading those publications, and associating with professionals, you know?

Connecting with folks in your trade can really give you exclusive information on the new tech and what's top-notch. And hey, don't forget about training the team on how to operate all that sophisticated equipment appropriately.

What are the future trends in garment testing technology?

The future's pretty bright for garment testing tech, with even greater exotic remedies coming soon. Thanks to considerable automation and artificial intelligence, we're going to see some really effective and exactly right testing machines.

These techs will not only boost your quality assurance, they'll also reduce the time and money it takes to complete the task. And getting that IoT (IoT) stuff into the integration in the testing context purposes will allow manufacturers monitor activities in live and get some valuable information to form judgments.

Related articles

- Innovative Solutions by Dumbbell-shaped Cutting Die Manufacturer

- The Luer Connector Standard: An Essential Guide

- Unveiling the Power of 5VA Flame Rating

- Why Explosion Proof Test Chambers Are Essential

- Call for Energy Efficiency: Industrial Fans Reimagined

- Innovate Your Textile Testing with Top Manufacturer

- Revolutionizing RCT Sample Cutting with Top Manufacturers

- Fabric Tearing Tester: Reviews