Events

Revolutionize Your Rotative Machine Skills with Coupons

News 2025-07-01 383

Ever since I started getting into rotative machines, I've been trying to continuously learn and getting better at it. As a mechanical engineer with more than ten years under my belt, I've had the chance to work with all sorts of rotative machines in various industries. Today, I'm sharing what I've learned and some valuable tips to help you upgrade your skills with rotative machines.

Components

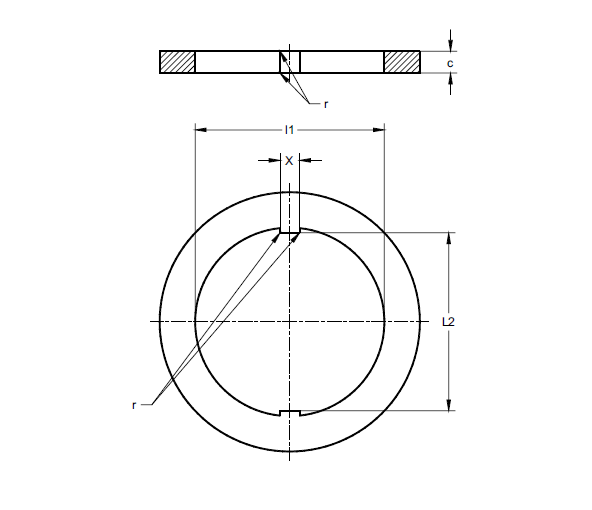

With rotative machines, it's all about the parts—they're like the heart and soul of how they work. I still remember the first instance I took a rotative machine apart to determine how it ticks.

I was astonished how intricate the components were—shafts, gears, and bearings, such things. It was like uncovering a treasure trove and revealing the enchantment of the machine. Through the years, I've gotten really good at diagnosing the issues with the parts, which has made me much more efficient and better at mending things.

Performance Optimization

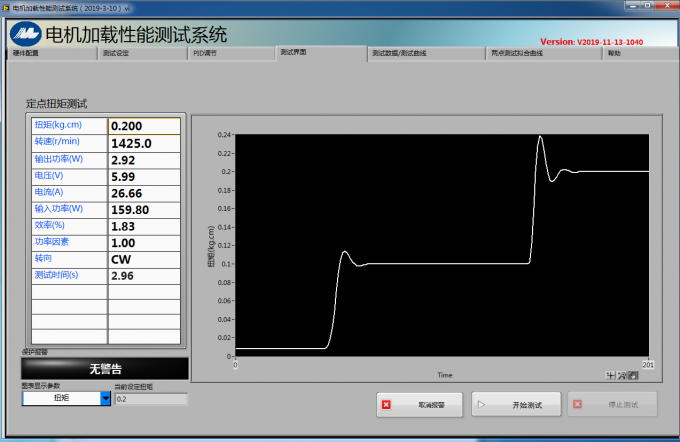

Making a rotative machine perform better is akin to an art form, really. You must be aware everything about the machine's structure, how it's supposed to run, and the setting in which it operates.

I've worked on a lot of projects where we were required to adjust these machines to optimize their efficiency and productivity. By adjusting the speed, load, and applying lubrication properly, we managed to reduce energy consumption and ensure the longevity of the machine. This experience has instructed me the significance of ongoing improvement and remaining abreast of the most recent technologies.

Safety and Maintenance

Safety is a big deal when you're dealing with rotative machines. I've witnessed firsthand the results of neglecting safety procedures, and it's a lesson I never forget.

You gotta keep up with the upkeep and periodic inspections to avoid incidents and make sure the machine operates properly. I put together a detailed upkeep schedule for stuff like inspecting for leaks, lubricant levels, and making sure everything's aligned. By sticking to this schedule, we've kept downtime to a minimum and made sure our machines are always in optimal condition.

Advanced Technologies

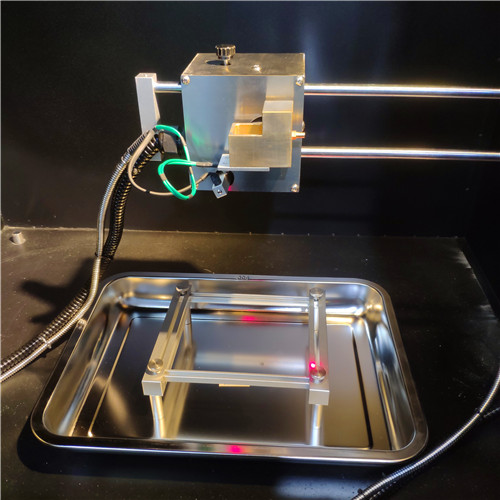

The rotative machine game is always evolving, and there's always new tech coming up. I've had the chance to work with some pretty exciting technology like IoT and AI, which have totally changed how we monitor and manage these machines.

This technology has not only increased productivity but also enables us conduct scheduled maintenance to decrease unexpected incidents if the equipment fails. Because of this, our team and myself have been noticed for developing novel methods and providing substantial contributions to the industry.

Related articles

- Secure Your Paper Tube Compression Tester: Find the Best Supplier

- The Essential Guide to Electronic Lock Flame Retardant Tester

- Call for Efficiency: Streamlining Medical Sampling with Prefilled Syringe Kits

- Priceless Journeys with Ibe MHlophe Indlela

- Unlocking EMC Experiences with Coupons

- Unveiling the Essence of Bursting Strength Test Machines

- Best surgical steel instruments: Your Ultimate Guide

- When Mechanical Shock Test Equipment is Essential