Events

Revolutionize Plybond Testing with Our Sale

News 2025-06-10 287

Starting the plybond testing thing, the internal plybond tester is pretty cool to have. This handy gadget has totally changed the game in composite testing. It's all about getting accurate and quick results.

1. The Importance of Internal Plybond Testing

2. Advantages of Using an Internal Plybond Tester

3. Types of Internal Plybond Testers Available

4. Maintenance and Calibration of Internal Plybond Testers

5. User Reviews and Success Stories

Whether you are a seasoned professional or a beginner in the industry, understanding the nuances of this tester is crucial. Let's dive into the five hot topics surrounding the internal plybond tester and explore how they can enhance your testing experience.

![]()

1. The Importance of Internal Plybond Testing

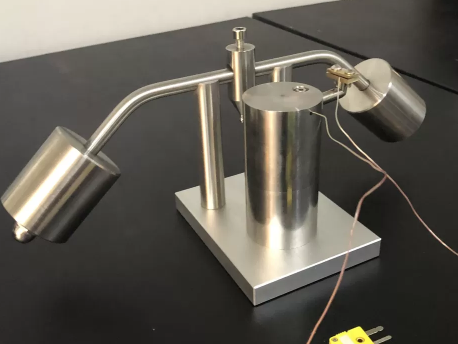

Internal laminate bonding testing is a crucial step in the manufacturing of composite structures. It makes sure the layers adhere to each other good, which is a big deal for how strong the material is.

This inspection routine helps detect any weaknesses or shortcomings in the plybond, preventing potential failures in the field. The ASTM experts say they gotta check this plybond thing for most composite structures. It's pretty much standard.

2. Advantages of Using an Internal Plybond Tester

Employing the tester, it's way better than traditional techniques, and it's got some good advantages. First off, it doesn't mess up the stuff you're testing. You can repeatedly utilize it without causing harm.

Furthermore, it gives you quick, precise responses, which helps companies make wiser decisions. And the best part? It's extremely user-friendly, so it's good for experts and beginners alike. A big aerospace company showed that this tester has reduced their testing duration and improved their products significantly.

3. Types of Internal Plybond Testers Available

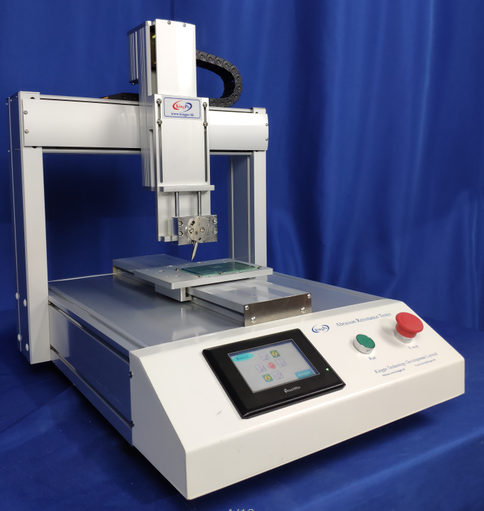

There's a whole bunch of these plybond testers out there, all with various unique features. The major types are the digital model, the manual version, and the portable tester.

Like the digital model, it gives you extremely accurate readings and functions efficiently with all automated testing equipment. Now, the manual version is more affordable and is more suitable for occasions with fewer tests. You gotta select the appropriate tester depending on your requirements and your budget constraints.

4. Maintenance and Calibration of Internal Plybond Testers

<p Caring properly of and calibrating these test instruments is huge for ensuring the results are correct. Frequent maintenance maintains the tester operates effectively and lasts longer.

And getting it calibrated makes sure the tester provides accurate readings. The ISO says you should calibrate these test instruments at a minimum annually. A pro from a reputable calibration company thinks you should keep up with the Upkeep and Calibration so you satisfy industry requirements.

5. User Reviews and Success Stories

People who use these test instruments are saying they're extremely useful, truly. An auto company guy says the tester helps identify and correct plybond problems early, which reduces the number of faulty components. A the construction worker commented that it's enhanced their quality inspections, satisfying the customers.

Related articles

- Who's in the Loop: A Deep Dive into Test Equipment Connection Review

- Mastering Paper Board Bursting Strength Testing

- Buy Wire Strength Tester - Quotes

- Why the IPX Waterproof Chart Matters

- Where to Find Reliable Universal Tensile Testing Machine Suppliers

- Why Choose a China Factory Inspection Equipment Company?

- Sale of Advanced Temp-Humidity Aging Test Gear

- Essentials of Basic Electrical Test Equipment