Events

Reviews of High and Low Temperature Heat Chamber: What You Need to Know

News 2025-08-14 281

So, when we talk about extremely high and low temperature chambers, they're super important in lots of industries, like aerospace and the car business. These heat chambers are designed to replicate extreme temperature conditions, so we can conduct tests on components under extreme conditions. In this article, we will explore five aspects that people usually ask about these heat chambers. We'll share some interesting information and practical examples to help you see their significance.

1. So, what are these heat chambers good for?

2. How do these heat chambers actually do what they do?

3. What are the main parts that make these heat chambers work?

4. How do I pick the right heat chamber for my needs?

5. Can these heat chambers be tailored to fit exactly what I need?

1. So, what are these heat chambers good for?

You need these broad temperature range temperature-controlled enclosures for material testing and doing research. They are used to determine how compositions and items perform under severe temperature settings.

Take the aeronautics sector, for example. These chambers simulate true low-temperature vacuums and super intensive thermal propulsion units. So, by putting materials through these kinds of tests, designers can make sure they're up to snuff and operational without issues in the practical applications.

2. How do these heat chambers actually do what they do?

These chambers apply a cold-system and some heating system components to keep the temperature just right inside. You can set the temperature really exact, from super super cold (-196°C) to super hot ( 200°C).

Becaapply of this, you can do lots of different tests, like really cold and really hot tests. These chambers make sure that the materials or stuff you're testing are always in the same, consistent conditions.

3. What are the main parts that make these heat chambers work?

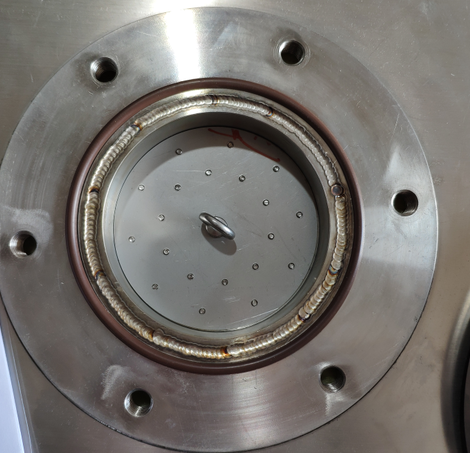

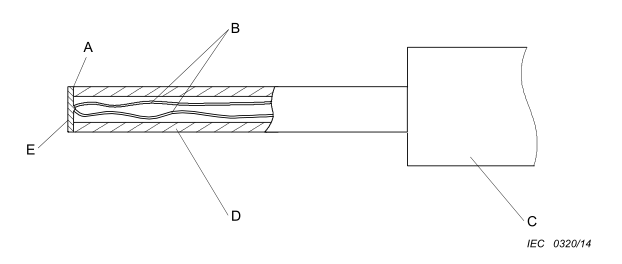

A heat chamber is kind of like a big, fancy box, and it's got a few important parts. These include the primary space, which is the enclosed space where the testing takes place; the cooling unit, which cools the chamber to the desired temperature; the heating components, which raise the temperature inside the chamber; and various monitoring and control system to regulate and hold the temperature. The way these parts are designed and how good they are make a big difference in how the chamber works.

4. How do I pick the right heat chamber for my needs?

Choosing suitable heat chamber is about not just selecting any. You gotta think about how low or high temperatures you need it to be, dimensions of the item being tested, and how precisely you need it to keep the heat. It's really important to work with a reliable vendor. They should give you suitable guidance and help you find the chamber that perfectly suits your needs. And don't forget to think about how the chamber's construction, how much energy usage, and the nature of the customer support and assistance they'll give you.

5. Can these heat chambers be tailored to fit exactly what I need?

Absolutely! You can usually get These heat chambers to be perfectly tailored to your requirements. That might mean they increase in size, have some advanced temperature control, or maybe even come with vacuum or humidity control. Tailoring them can ensure the chamber is a good fit your distinctive application needs just right, giving you highly precise outcomes.

Related articles

- Used Testing Equipment Electrical: A Comprehensive Guide

- Essential Requirements for IEC62368 Test Equipment

- Foam Tester Product: What You Need to Know

- Mastering Wyzenbeek Test: Unveiling Its Real-World Applications

- Comprehensive Guide to Laboratory Testing Equipment List and Uses

- Essentials of Protective Equipment Testing Instruments

- Why ISO 80369-7:2021 is Critical for Medical Device Innovation

- The Essential Role of Conical Gauge in Modern Engineering