Events

Precision at Play: The Aluminum Testing Instrument Scene

News 2025-06-06 312

Ever think about how they confirm their metal stuff is top-notch? Well, the crucial factor is in the really precise devices they use to test it. These devices are like the unsung heroes in the metal industry, making sure each item of metal is super-excellent quality. So, let's dive into the five major aspects about these testing devices, and I'll share some interesting insights, success stories, and my personal experience.

1. How Aluminum Testing Tools Have Changed Over Time

2. Keeping Them Super Accurate and Trustworthy

3. The Magic of Non-Damaging Tests

4. How These Tools Have Gotten So Cool

5. Why Teaching These Guys Matters

1. How Aluminum Testing Tools Have Changed Over Time

Back in the day, the tech for These devices was way different from what we have now. Back then, we had these large, slow machines that were highly susceptible to committing errors.

Now, we have these digital devices that provide us with real-time data, are extremely accurate, and are very easy to use. I love this story about a client who upgraded from their old gadgets to the new digital ones. And guess what? They reduced their production time by 20% and their quality went up significantly.

2. Keeping Them Super Accurate and Trustworthy

Accuracy and trustworthiness are key with These devices. A significant issue I've had to deal with is ensuring These devices are all precise and reliable.

It is primarily about ensuring strict control over things, like regulating the temperature, modifying the pressure, and ensuring their cleanliness. I read this review about the company's device that was extremely consistent and dependable, and it enabled them to secure a significant contract.

3. The Magic of Non-Damaging Tests

Non-destructive testing is a major significance in the game of testing aluminum. It implies that they can inspect the materials without causing damage to them.

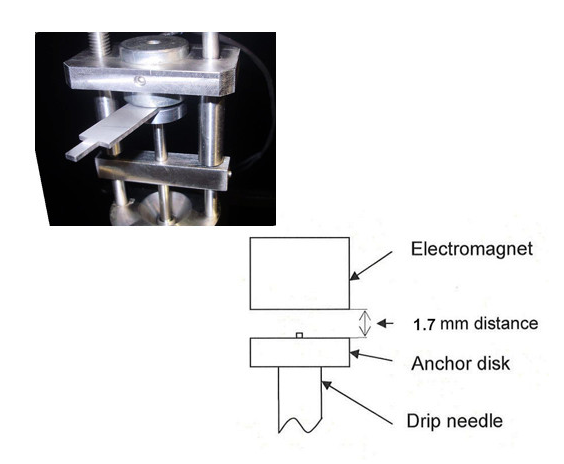

I recall a specific instance when I had to use this non-damaging stuff to test a bunch of aluminum parts for a client. Using this magnetic particle technique, we found defects and other problems, preventing future failures. These non-destructive tests are rapidly gaining popularity and they're significantly improving products.

4. How These Tools Have Gotten So Cool

These gadgets have really come a long way in design. Now, these gadgets are small, portable, and have all sorts of amazing features like wireless connectivity and software that analyzes data.

I remember a time I had to go to some distant location to test some aluminium pieces for a customer. The new design was a major convenience; it made examining so much easier and I could quickly provide feedback. It's made life a lot easier for numerous manufacturing companies.

5. Why Teaching These Guys Matters

Like any technology equipment, these gadgets need to be handled right. That's why training and certification for the users are so important. I've seen it myself how excellent training can significantly improve in the accuracy of the tests. I saw this example where a company trained their employees, and it resulted in improved outcomes and more satisfied clients.

Related articles

- Best Electronic Tensile Strength Machine Deals

- The Rise of Energy-Efficient Industrial Fans

- IEC Equipment: A Comprehensive Guide

- Why China's Arc Welding Equipment Welding Cable is a Game Changer

- What Test Equipment USA Reviews Reveal

- Electrodynamic Vibration Shaker Coupons: Power Up Your Testing

- Why the Best Testing Equipment for Electrical is Essential

- Unveiling the Hidden Costs of Corrugated Cardboard