Events

Optimizing Cables Heat Aging Test Chamber Performance

News 2025-08-04 323

You've probably thought about how cables endure over time frame, particularly when they become very hot, right? Well, meet the cables heat aging test chamber - it's important thing for maintaining cables' quality for a long time frame, regardless of the industry. It doesn't matter if it's a car, a plane, or electrical components; knowing how these testing facilities functionality is really important. So, let's explore five crucial points about these cable testing chambers that everyone's wondering about.

So, what is this cables heat aging test chamber thingy, anyway?

Now, how does this whole cable heating test room thing work, you ask?

Why would anyone want to heat up cables and put them through this stress testing, you ask?

So, how do you pick the right kind of hot cable testing place for your needs, right?

Alright, how can the folks who make cables get the most out of their hot rooms, you ask?

So, what is this cables heat aging test chamber thingy, anyway?

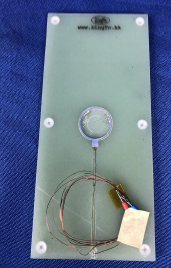

A heat aging test chamber is like a unique space that lets us see what happens to cables when they get extremely hot over time. We make cables super hot for a long time in there, kind of like a authentic examination. This helps makers figure out any flaws and make better cables.

Now, how does this whole cable heating test room thing work, you ask?

These spaces raise the temperature the cables to a particular temperature, considering which type of cable it is and which test they're doing. Following this, we leave the cables in the hot room for a while, then inspect them to see if there's any wear and tear, like crevices or discoloration, or if they do not function as expected.

Why would anyone want to heat up cables and put them through this stress testing, you ask?

This kind of testing is really important to Ensure cables will have a long lifespan and function properly. Think of all those high heat places such as car engines or electrical circuits; cables are put to the test in those spots. Doing these tests helps the manufacturers of cables spot potential issues before they turn into greater complications, which means this is more intelligent, cheaper manner of proceeding.

So, how do you pick the right kind of hot cable testing place for your needs, right?

When you're looking for the right hot place to test cables, you need to consider things like how size of it, the kind of temperature range it supports, and how it can perform tests. And don't forget, this test chamber has gotta comply with regulations and be able to perform as intended, like replicating actual conditions as close as possible.

Alright, how can the folks who make cables get the most out of their hot rooms, you ask?

To get the best out of your cable heat testing area, you gotta do some smart practices. Regular maintenance, using high-quality materials, and keeping it all tuned up for reliable results are key. Additionally, incorporating state-of-the-art features, such as automated data gathering and examination, can help optimize the testing procedure and improve general efficiency.

Related articles

- Why the Electrical Wire 60227 IEC 01 is a Key Component

- The Necessities of IT Product Testing Equipment When Ensuring Quality

- Audio Analyzer Test Equipment: Essential Demands and Insights

- Mastering Prestressed Steel Strand Applications

- Mask and Medical Protective Clothing Detection: A Comprehensive Overview

- Where PIM Cap 4 Meets Modern Needs

- VDA Lithium-ion Battery: A Deep Dive into Quality and Innovation

- Why Precision Matters in Medical Electronic Equipment Testing