Events

Mastering the Art of Drop Ball Shock Testing

News 2025-07-05 338

So, I've worked as an engineer who's interested in material testing, and I've used all sorts of gear. The drop ball shock tester is one of the cool gadgets I've discover. This thing is a must-have for everyone who is involved in testing and making sure materials are up to snuff, especially in the context of in vehicles like cars and aircrafts. In this piece article, I'm gonna dive into the details of drop ball shock testing and share my opinions and what I've learned.

Standardization and Calibration

Material Selection and Quality Control

Impact Resistance Testing

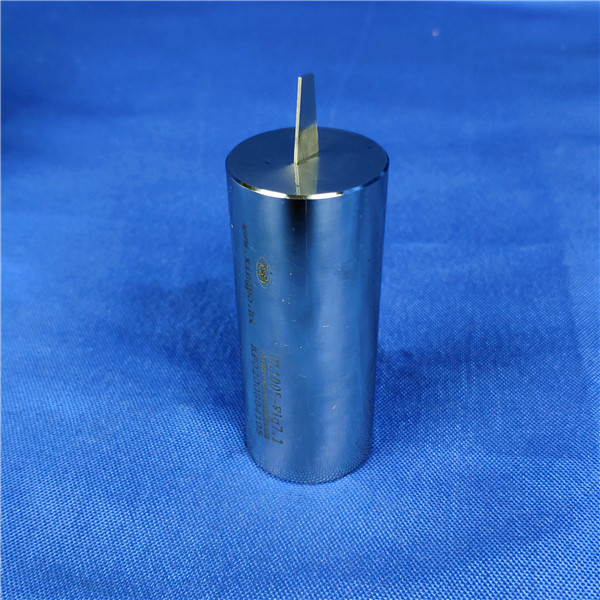

Determine how material withstands impact is key. It tells us how its behavior will be during a sudden load. I have employed this testing device to test how resilient materials such as metals and plastics, and advanced materials can take a impact.

You release a ball from a set height onto the material, and you watch how it modifications and damage, maintaining detailed notes of the mess. This info is super important for engineers who want to make sure their stuff doesn't fall apart in everyday situations.

A good example is using these testers in the automotive industry to make sure bumpers and stuff can hold up in a accident. These tests make sure the car components such as bumpers and doors can withstand an impact without bending or breaking. By knowing how the material deals with a jolt, engineers can make cars that are safer and won't let you down.

Standardization and Calibration

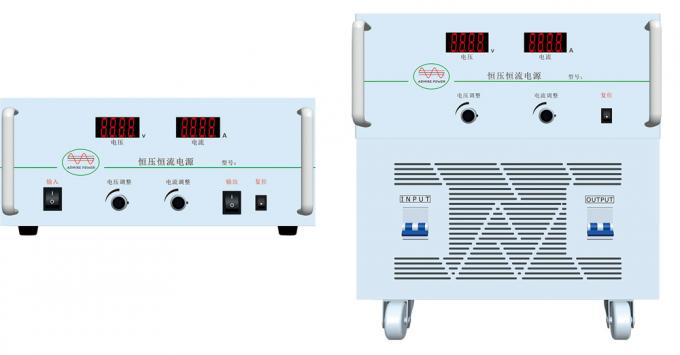

Maintaining all uniform and correctly calibrated is extremely important in drop ball impact testing. As an expert, I've have always stressed the significance of employing accurate instruments in order to guarantee precise and dependable findings.

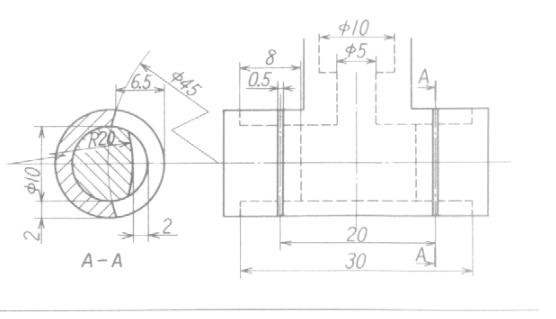

You must ensure the tester is accurate. Even a slight inaccuracy can severely compromise the results. During calibration, you tweak the machine so the ball hits exactly right, and it consistently applies the appropriate amount of force.

An important aspect of calibration is ensuring the ball remains spherical and maintains its weight over time. This is crucial because the ball's shape and weight are significant as they determine the impact strength of the ball on the material. By meticulously monitoring these aspects, we can have confidence in the accuracy of our results and demonstrate the material's true capabilities.

Material Selection and Quality Control

An interesting aspect of drop ball shock testing is is its ability to select appropriate materials and maintain quality. I've employed this tester to determine which materials are suitable for specific applications. For instance, in the production of parts for items that are frequently subjected to impact, such as sports equipment or construction materials, selecting materials that can withstand impact without breaking is necessary.

By performing these trials, we can find the optimal components for a job, making sure the final product will perform its intended function. This is also key for checking item criterion over duration, letting producers keep an eye on how their ingredients and finished goods perform.

Conclusion

So, as an technician with lots of knowledge in material evaluation, I really get why the drop ball shock tester is so important for making sure items are security and dependability. This handy instrument has assisted me and my group make informed decisions about what we're using, how we're item conception, and making sure our high standard. No matter if you're in motor vehicle assembly, aeronautic production, or any other sector that uses robust components, knowing the details and nuances of falling ball impact evaluation can help you improve choice-making and construct securer, more reliable items.

Related articles

- Revolutionize Your Materials Testing with Promo Rubber Tensile Testing Machines

- Strategic Plans for Packaging Leak Tester Suppliers

- Drop Test Steel Ball: Essential Demands and Insights

- Mastering Walk-In Stability Test Chambers

- Navigating the Brittleness Temperature: A Comprehensive Guide

- SAR's Role in Modern Technology When Needed

- Where Dokunmatik Test Kodu Meets Quality Assurance

- The Essential Guide to ECG Testers