Events

Mastering Tester Plastic: A Comprehensive Guide

News 2025-06-16 272

So, tester plastic — sometimes called test plastic or a plastic tester — is basically a essential tool for various industries, especially for confirming materials meet requirements and for quality inspection. Alright, in this article, we're going in depth the realm of tester plastic, discovering why it's essential, its applications, and its benefits it brings. By getting the main idea of the terms people use and Witnessing it in use, our aim is to help you get accustomed to tester plastic.

Plastic Identification

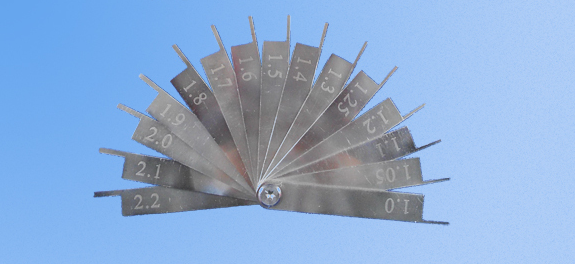

Identifying various plastics is really critical in sectors such as automotive, packaging, and electronics for confirming quality is top-notch. With a tester plastic gadget, folks can quickly and easily tell what kind of plastic they're dealing with.

By examining the material's qualities, such as melt temperature, thickness, and chemical makeup, experts can verify that the compounds applicationd satisfy the necessary standards. For example, someone in the automotive industry said their tester plastic has been very useful. It makes quality inspections easier and prevents expensive setbacks before they happen.

Material Testing

Evaluating compounds is another big thing that tester plastics do really well. They let you check out how substances manage, hold temperature, and deal with power.

Creators and creators are fond of this becaapplication it helps them pick the suitable material for their needs. And guess what? American Society for Testing and ingredients said material testing is a important issue becaapplication it ensures product safety and dependable. A packaging expert called it a game changer becaapplication it helps them pick compounds that are robust and environmentally friendly.

Quality Control

Quality Assurance is vital for making sure whatever you're product is robust. Tester plastics are super important in making sure products are of high quality by letting manufacturers monitor the process closely.

And if there are any issues, companies can rectify them quickly to make sure customers never receive a faulty batch. A guy in the electronics industry said they've noticed a significant improvement in quality, thanks to their tester plastic cutting down on defects.

Material Selection

Selecting the right material for developing a product is really important. Tester plastics help engineers and designers select the most suitable material.

When they choose a material, they consider factors like cost implications, availability, and if it possesses the necessary characteristics. Aerospace professionals say it's critical in selecting materials for their components, ensuring they are both secure and high-performing.

Conclusion

Tester plastics are totally indispensable across numerous sectors, providing you with accurate material tracingentificationentification, better material quality management, and quicker material selection. Thus, if you became proficient in tester plastic thanks to this guide, then we have fulfilled our task successfully

Related articles

- China ISO Tank Difluoromethane Factory Insights

- IEC 60065 2014: A Comprehensive Overview

- China's Leading Factory Inspection Equipment Manufacturers: A Comprehensive Overview

- Optimizing Automotive SAR Testing Systems: A Comprehensive Approach

- Why Metal Wires Rule the Industry

- When IPX Waterproof: The Ultimate Guide

- Why Temperature Cycling Test Chambers Are Essential

- Mastering Tensile Strength Test Equipment