Events

Mastering Characteristic Yield Strength of Steel

News 2025-06-29 356

The inherent yield strength of steel is extremely significant in materials science and engineering field. It's the most stress steel can handle before it undergoes permanent deformation.

1. Determining the Characteristic Yield Strength of Steel

2. Impact of Yield Strength on Steel Properties

3. Role of Yield Strength in Steel Fabrication

4. Yield Strength in Steel Selection

5. Advancements in Testing and Measurement Techniques

Comprehending this concept is crucial for multiple applications, from construction to car manufacturing. In this paper, I will delve into five key areas related to the characteristic yield strength of steel and offer insights for each.

1. Determining the Characteristic Yield Strength of Steel

In materials engineering, we really need to get the characteristic yield strength of steel right. We do this by elastically deforming test specimens to see when they start to plastically deform.

It's key for making sure our structures and parts can resist under specific stresses without breaking. The ASTM International (ASTM) says that steel's stiffness can vary a lot depending on how it's made and treated.

2. Impact of Yield Strength on Steel Properties

Steel's stiffness can really affect how much it can elastically deform, bend, and dampen vibrations. Stronger steel means it can bend and rotate more before failure, and it generally performs more effectively.

But on the flip side, extraordinary steel can be more prone to breaking all of a sudden, like a shattering glass. We gotta find a optimal point between strength and other things like pliability to meet what we need for each job. The ECISS (ECISS) says we should think about steel's strength when we're selecting materials for design.

3. Role of Yield Strength in Steel Fabrication

When we're making things out of steel, we gotta make sure the strength is enough to keep the parts from buckling or fracturing. Like, when we bend or shape steel, we need to maintain its strength within the limit so it doesn't irreversibly bend.

If we overload it, the steel can weaken and might even break. Engineers need to determine precisely how strong the steel needs to be to make sure our stuff is safe and reliable. The IIW (IIW) says we need to focus on the strength of steel in making things and gives engineers tips on how to do it correctly.

4. Yield Strength in Steel Selection

Choosing suitable steel for a job is about looking at different things, like how strong it is. Engineers need to figure out what kind of stresses and environments the steel will face to pick one that's strong and long-lasting.

For example, we usually go for strong steel when we need to support heavy loads. But we also have to think about things like how much it cost, if it's readily available, and how it can be manufactured. The WSA (WSA) talks about how to pick suitable steel and gives advice to designers and engineers.

5. Advancements in Testing and Measurement Techniques

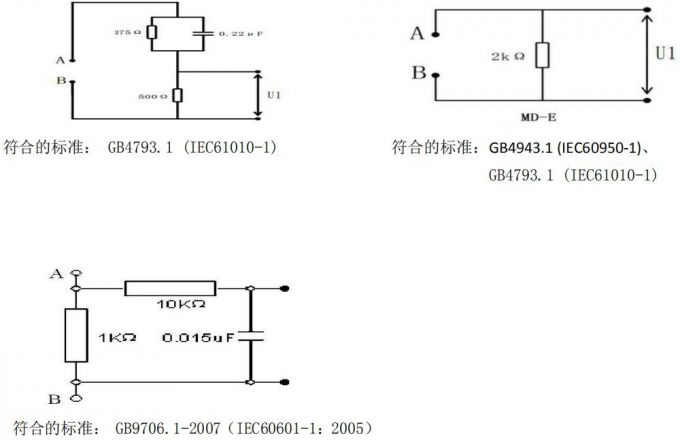

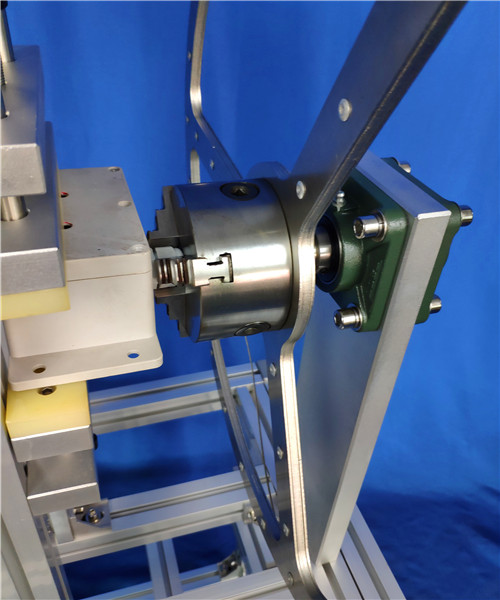

New ways of testing and measuring have manufactured it a lot easier and more reliable to figure out how strong steel is. Contemporary testing equipment, like all-purpose testing machines and electronic extensometers, lets us determine characteristics extremely precisely.

These advances let designers get a greater understanding on how steel behaves in various conditions and help them make their blueprints and construction methods refined. The journal points out how crucial these advances are for ferrous engineering.

Related articles

- Mastering the Art of Universal Testing Machines

- How to Find Quality Testing Equipment for Sale

- When Packaging Clamping Testing: Essential Demands and Insights

- The Essential Guide to Wedge Grips

- How to Ensure Accuracy in Radiological Imaging Equipment Testing

- Innovative OT Instruments: Top 5 Hot Demands

- How to Optimize Switch Test Equipment

- Revolutionize Your Projects with Steel Sheet Materials