Products

IPX1~IPX6 Comprehensive Water Ingress Testing Equipment , Stainless Steel Chamber IEC 60529

Products Description

IEC 60529 IPX1~IPX6 Comprehensive Water Ingress Waterproof Stainless Steel Test Chamber

Overview:

Application background: Natural water (rain, sea water, river water, etc.) damages products and materials. The damage causes unpredictable economic losses every year, mainly includes corrosion, fading, deformation, strength reduction, swelling, mold, etc. especially for electrical product that is easily broken into a fire due to a short circuit caused by rain. Therefore, IP code testing for specific products or materials is an essential key procedure.

Application areas: outdoor lighting, household appliances, auto parts and other electronic and electrical products.

Equipment function: The equipment is for testing electronic and electrical products, lamps, electric cabinets, electrical components, automobiles, motorcycles and their parts and components’ physical and other related properties under simulated climatic conditions. After the test, it is judged whether the performance of the product meets the requirements, so as to facilitate the design, improvement, verification and factory inspection of the product.

Standards compliant: IEC 60529: 2013 Degrees of protection provided by enclosures (IP Code).

Equipment Features:

1. It is suitable for IPX1, IPX2, IPX3 , IPX4, IPX5, IPX6 waterproof grade test.

2. The shell is made of high-quality steel plates, beautiful and durable.

3. The drip board, inner chamber, turntable and other wading parts are all made of SUS304 stainless steel to ensure no rust for long time use.

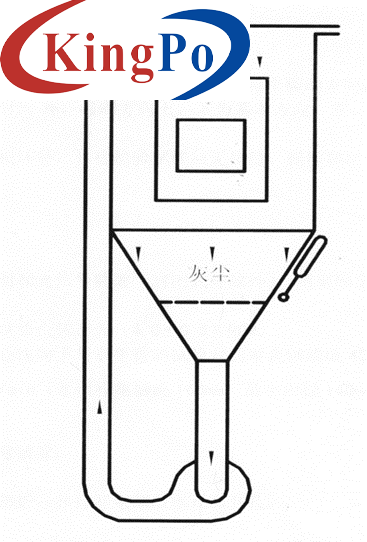

4. The drip tank is with vacuum designed and high-rust stainless-steel construction; the nozzle contact position adopts brass cone design, which is convenient for installing the spray nozzle.

5. The water supply pipeline is equipped with a filter, which can filter impurities in the water, so as to prevent nozzle clogging.

6. With compressed air-drying function, after the test is completed, the excess water in the drip tank can be removed to avoid prolonged water fouling and block pinholes. (Note: users need to provide compressed air supply).

7. The turntable uses a stepping motor, the speed can be set on the touch screen, can reach to the speed of 1 rev/min required by the IPX1 standard, and the IPX2 test of dripping 2.5 minutes in 4 positions separately can be automatically completed.

8. The oscillating tube is driven by high-quality servo stepping motor, the swinging speed and angle are precisely adjustable, and here is no out-of-step problem (out of step: it will cause the malfunction of the oscillating tube, the oscillating tube may hit the middle turntable shaft, and cause equipment damage).

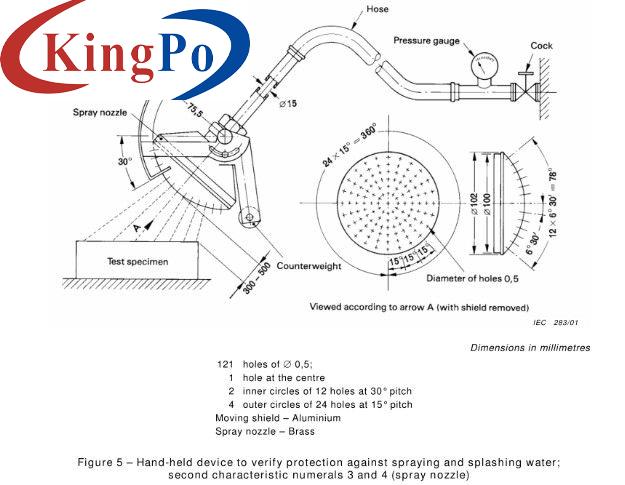

9. The IPX3/4 spray nozzle and IPX5/6 hose nozzles are made according to following:

10. A power outlet is built-in this chamber, the power on/off time for specimen can be controlled by the program: power off (0-999min), power on (0-999min), power off (0-999min).

11. A waterproof LED lighting is installed in the test chamber, and there is a large observation window on the door to facilitate the observation of the test inside the chamber.

12. The equipment comes with a water tank for recycling water, user does not need to build a professional waterproof test room. There is a float valve in the water tank, which automatically controls the water inlet and has the function of high and low water level alarm monitoring, to effectively prevent the pump from being damaged due to dry water shortage.

13. The core control components adopt the 7-inch touch screen + Mitsubishi or Panasonic PLC; the electrical components adopt imported branded ones such as LG and Omron; the wiring process conforms to the international standard requirements, the layout of the electric board is reasonable, the wiring is firm, and the marking is clear.

14. Self-developed IPX waterproof level test operation interfaces, operator directly select the relative waterproof level on the touch screen to process corresponding IP Code testing as per standard requirements automatically, the operation is simple and humanized.

15. The base of the equipment is equipped with 4 movable brake casters for easy movement and fixing.

Technical Parameters:

Basic Parameters

Chamber inner size

W 900mm* D 900mm* H 1050mm

Chamber external size

About W 1350mm* D 3400mm* H 1750mm

Turntable diameter

¢400mm (Can be equipped with ¢200mm, optional)

Turntable maximum load bearing

50KG

Turntable lifting height

400-750 mm

Turntable tilt angle

0° or 15°(horizontal direction)

Turntable rotation speed

1 -5r/min (accurately adjustable)

Turntable rotation direction

Always forward / positive and negative alternate / intermittent rotation

Flow adjustment method

Manually adjust the flow by adjusting the flow meters on the panel

Testing time

0-999 min

Total equipment weight

250kg

IPX1 IPX2 Technical Parameters

Drip area

600*600mm

IPX12 nozzle size

Diameter 0.4mm

Distance between drip holes

20*20 mm

Water flow

IPX1=1mm/min; IPX2=3mm/min

Drip board lifting method

Not lifting (fixed)

IPX3 IPX4 Technical Parameters

Oscillating tube radius size

R400mm(Can be equipped with ¢200mm, optional)

R400 oscillating tube water flow

IPX3=1.1L/min; IPX4=1.8L/min

Water spray aperture size

0.4mm

Water spray aperture distance

50mm

Oscillating tube inner diameter

15mm

Oscillating tube angle

120º(IPX3), 350º(IPX4)or defined

Oscillating tube swing angle

240° back and forth, 4S; 720° back and forth 12S (precise control) or defined

IPX5 IPX6 Technical Parameters

IPX5 nozzle aperture

6.3mm

IPX6 nozzle aperture

12.5mm

IPX5 water jet flow

12.5±0.625 L/min

IPX6 water jet flow

100±5L/min

Water pressure (Mpa)

Regulate the pressure according to prescribed water flow

Water jet distance

2.5m (nozzle away from the center of the turntable)

Nozzle fixing method

Mechanical fixing

Electrical Parameters

Equipment power supply

380V or meet client’s local power supply

Test sample power supply

220V or meet client’s specimen power supply

Equipment power

3.0KW or meet client’s local power supply

Security protection

Leakage protection, water shortage protection, short circuit protection