Events

Innovative Textile Tensile Testing Machines: Reviews and Insights

News 2025-05-21 418

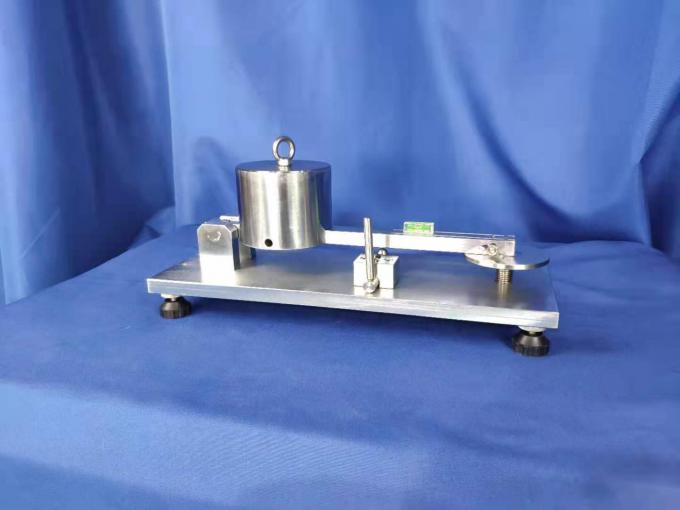

Man, the fabric industry just can't do without those tensile strength machines. They're super critical in maintaining fabrics strong and long-lasting. These devices are very important since they evaluate fabric strength and elasticity. The purpose is making sure the fabric is suitable, right?

Materials Testing

Exactly, Material Evaluation is key in this game. The purpose is examining fabric and fiber durability when you stretch them. With a tensile testing machine, companies can determine material's resistance to stress tolerance before failure occurs.

This info is huge for producing robust and reliable textiles, for sure. Take cotton like, for instance; the device provides a sense of its toughness and flexibility. It helps manufacturers adjust their procedures for the best results. I've acquired several techniques throughout the years. I deal with challenging material testing issues by doing extensive research and examining information from different places. All this means I can make informed decisions and make our stuff even better.

Performance Testing

Performance Evaluation? That's another essential in the textile industry. Tensile strength testing devices help us see how fabrics handle stress, which is key for knowing how they'll fare in practical applications.

Like, evaluating the robustness of fabric for outdoor stuff can tell us how it'll perform under adverse conditions. Looking at the test data, I've been competent to identify any vulnerabilities and implement improvements to enhance our products. This has elevated our performance and satisfied our customers more with the stuff.

Quality Control

Quality Assurance is extremely crucial in the industry, and those inspection equipment are vital for ensuring the items meet the standard. Consistent testing catches any obstacles or discrepancies early, so we can intervene and resolve obstacles.

I've seen the Quality Assurance improve considerably with these inspection equipment. Monitoring the inspection outcomes has helped me spot patterns and developments that let us prevent any issues.

Technological Advancements

Those inspection equipment have come a long way and brought some serious technical improvements to the fabric industry. These days, machines are way smarter with their automated control mechanisms. It makes testing more accurate and faster.

As I've tried to improve our testing procedures, I've found that using these technical improvements helps us get greater accurateness in outcomes and keeps our production process streamlined. This has been a major achievement for us, keeping us in the game as the market evolves quickly.

Related articles

- The UL507 Standard: An Overview and Key Requirements

- China Vacuum Pump for Vacuum Oven: Your Ultimate Guide

- The Versatile Role of Loading Pads Where They're Needed

- The Significance of a Constant Temperature and Humidity Oven

- Accurate Personaldienstleistung GmbH: Navigating Success

- IPX3 vs IPX4: A Comprehensive Guide to Water Resistance

- Insights on Cobb Absorbency Tester Quotes

- Unveiling the Best Thermal Chambers for Sale