Events

Innovating with Pneumatic Control Systems

News 2025-07-16 342

This type of pneumatic control systems are like game-changers for lots of industries. They are highly reliable and energy-efficient. They operate by utilizing air pressure to control machines and processes. This is why they are widely used in places like Automotive manufacturing facilities and packaging plants. So, today we're looking at five big themes around These type of systems, Discussing actual case studies, and getting some pro insights to help you Gain a comprehensive understanding.

Number one: all the cool tech advances in pneumatic control systems.

Number two: all about saving energy and being eco-friendly.

Number three: it's all about keeping things safe and super dependable.

Number four: how these systems get all connected with the Internet of Things.

Number five: all about making these systems fit just right for whatever you need.

Number one: all the cool tech advances in pneumatic control systems.

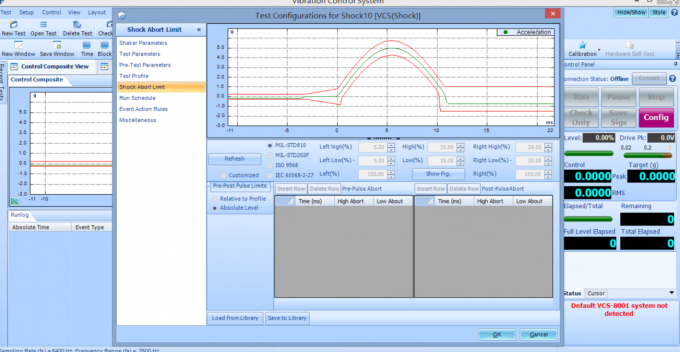

The best part about these systems is all the modern technology that's always popping up. Like, adding intelligent sensors and AI makes them super precise and helps with predicting when they need maintenance.

I worked on a initiative where we added a innovative sensor set that reduce downtime a lot and made the whole process smoother. The data we got was super valuable for improving our procedure.

Number two: all about saving energy and being eco-friendly.

As people get more into environmentally conscious, making these systems power-saving is really important. New systems are built to decrease energy consumption, which helps reduce costs and contribute to environmental well-being.

I saw a study that said using conserving energy systems can help you conserve up to 30% on energy energy expenses. That's a significant impact for businesses that want to be environmentally conscious and save some money at the same time.

Number three: it's all about keeping things safe and super dependable.

Safety's huge in manufacturing facilities, and compressed air systems are the same. People know these systems for being super reliable and safe.

They can be set up with safety features to interrupt operations in case of malfunction. I've seen it happen myself. A good system can stop machines right away if there's a problem, and that prevented an injury.

Number four: how these systems get all connected with the Internet of Things.

The IoT has really brought some new innovative features to these systems. Connecting them to IoT means you can keep monitor and manage ongoing activities in immediate, making optimal decisions and keeping things running smoothly.

A buddy of mine in manufacturing has seen a significant increase in their operations since they connected their systems to IoT. They use the data to adjust their production timetables and reduce waste.

Number five: all about making these systems fit just right for whatever you need.

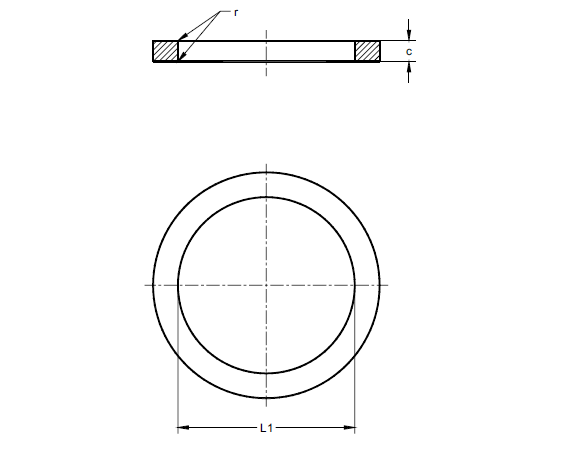

Another cool thing about these systems is how they can be customized to fit whatever you need. You can adjust them to meet the specific requirements of different jobs.

I've worked on jobs where we had to adjust the systems to meet particular requirements. That adaptability means they can be readily altered to fit new circumstances.

Related articles

- Unlocking Precision: Free Calibration Services Close to You

- Innovating with Universal Testing Machine Suppliers

- The Essential Guide to Temperature Cycle Test Chambers

- The Essential Guide to Rubber Thickness Gauge

- Revolutionizing Spraying: Universal Spray Nozzle Plans

- Wholesale Construction Rubber Foam: The Ultimate Guide

- Mastering Drop Tester Manufacturing: A Comprehensive Guide

- Discounted Test C Line: Unveiling the Hidden Gems