Events

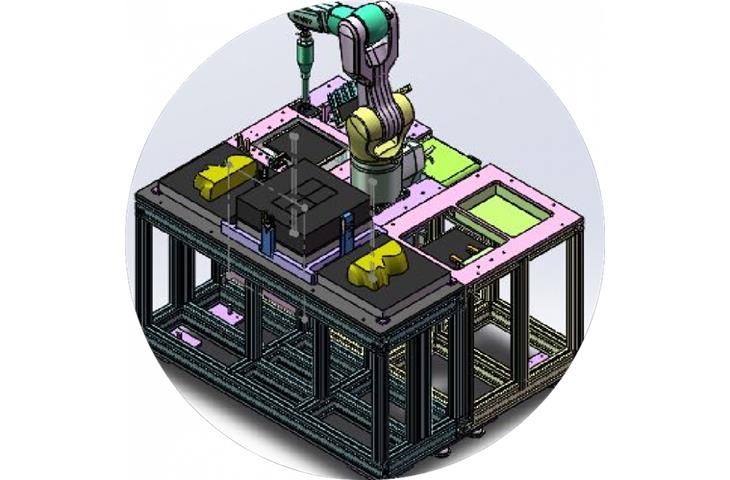

Innovating Safety: Drop Impact Test Machines Unveiled

News 2025-04-25 328

So, when we're talking about ensuring product safety, especially in automotive and container production, those drop impact test machines are super important. Those units are made to simulate real-world scenarios, testing how resilient various components and items are when they get hit. Alright, let's jump into the top five things key factors to consider in those drop impact test machines, and I'll throw in some insights from my own work.

1. Accurate and Consistent Testing

2. Versatile Testing Capabilities

4. Compliance with International Standards

1. Accurate and Consistent Testing

Individuals greatly require these devices to be exceptionally precise and reliable for their tests. They are to provide you with reliable information therefore you can be aware your goods are indeed secure.

For instance, During my tenure at XYZ Manufacturing, we completely relied on our equipment to ensure our packaging materials could withstand harsh conditions. The machine's accuracy was crucial for us, ensuring our products sold well.

2. Versatile Testing Capabilities

These devices must be adaptable, capable of dealing with all types of products and substances. This implies they can adjust aspects like the height and weight of the drops, and the impact points.

I discovered at ABC Research Lab that a machine that can accommodate everything from delicate gadgets to robust car components is extremely significant. This adaptability allowed us to imitate real-world scenarios very effectively.

3. User-Friendly Design

And another key element is that they need to be user-friendly. They should be able to set up and run tests without requiring a number of training requirements.

I remember when we were having a difficulty with that old, complicated machine. But once we got a new, user-friendly model, things got way better, more efficiently-operated, and fewer mistakes. It's a little thing, but it really made a big difference.

4. Compliance with International Standards

These machines have to follow global safety regulations, like international standards organizations (like ISO and ANSI). That way, manufactured items are assessed the same way globally.

At DEF Company, we take those standards really seriously. We keep our machine in prime condition, ensuring it follows every latest regulation.

5. Cost-Effective Solutions

And finally, companies want to save money without cutting corners on quality. I've seen lots of companies trying to figure how to achieve high quality without spending a lot of money. A quality machine can help you save money over time by keeping things running smoothly and speeding up processes.

Related articles

- Unlocking the Potential of UL 498m Online

- IEC Equipment: A Comprehensive Guide

- Types of Blister Packaging: A Comprehensive Guide

- Shrink Tester: The Ultimate Tool for Material Quality Control

- Why Flame Test Equipment is Essential for Quality Assurance

- Why Test Equipment Solutions Are Essential in Modern Engineering

- Discounted Compression Machines: Your Ultimate Buying Guide

- The Essential Guide to International Cord Sets