Products

IEC60950 Household Electronic Ground Bond Test Equipment Fuse 2-500mΩ

Products Description

SN9613 series intelligent automatic grounding conductive resistance tester has a constant current 5A-30A output with a frequency of 50/60Hz, it could conduct a grounding resistance within 500mΩ. It has the highest resolution of 0.1mΩ and precision of 2.0% at the highest compared with another similar tester. The equipment is with high performance and easy operate at the same time, so it could meet the requirement of online test of the production line, also it meets the high precision requirement of lab testing. The equipment supports to communicate with computer and automatic production line via its RS-232 interface.

IEC60950 Household Electronic Ground Bond Test Equipment Fuse 2-500mΩ

Applied standards:

The electrical design meets the standard of GB4706.1, GB4943, GB7000.1, GB3883.1, and GB / T12113, as well as the international electrical committee standards such as IEC60335-1, IEC60950, IEC60598-1, IEC60745-1, and IEC60990.

General parameters:

PLC remote control

Signal input: Start

Screen

16*2 blue LCD display

Communication interface

RS232(optional)

Calibration

Software

Working environment

0-40℃, 20-80%RH

Input voltage

0-40℃, 20-80%RH

Input frequency

50/60Hz

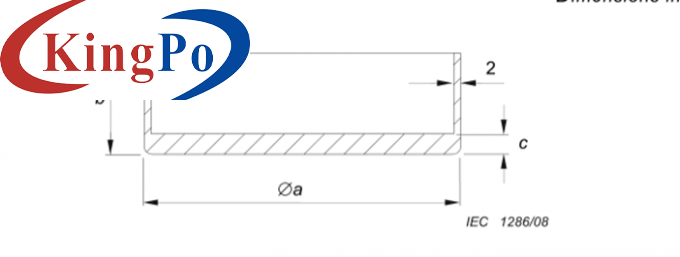

Fuse

Fuse 5A

CBM

280mm(W)×89mm(H)×380 mm(D)

Current output range

5-30A (32A/40A optional)

Current output precision

± (2% * setting value )

Current output stability

Less than 0.3% (10A/100mΩ)

Frequency and precision

50Hz/60Hz ±0.2%

Grounding resistance measuring range

5-500mΩ(5-10A)

2 – 200mΩ (11-25A)

2 – 150mΩ (26-32A)

Grounding resistance measuring precision

± (2% * reading value + 3mΩ)

Test time and resolution

0,0.5-999.9s,resolution 0.1s, 0 means output constantly

Daily maintenance

The operation environment of the equipment should be well ventilated, dry, without dust and strong electromagnet interference

Please power on regularly if the equipment is not be put into use for long time, at least 30 minutes and once per month is suggested.

The power supply should be turned off for more than 10 minutes after a long time (24 hours) working, so that the equipment keeps in good performance

A regular maintain of the test clamps is necessary, because a contact fail or break circuit probably appears after long time usage.

Regular maintenance

This input power line, test wire, test socket and relevant accessories of equipment must be carefully checked and calibrated at least once a year to protect the safety of the users and the accuracy of the equipment. If the equipment is used in production sites or other harsh conditions, the maintain cycle should be shortened as per the operation environment.