Events

High-Temperature Powerhouses: The Evolution of Ceramic Matrix Composites

News 2025-06-23 301

High-Temperature Ceramic Matrix Composites, these powerful materials, have been breakthrough materials in extreme thermal conditions, with their high thermal stability and high strength. These materials, they're known to handle severe conditions like a boss. They've been driving technological progress lately, too.

3. Mechanical Strength and Durability

4. Application in Aerospace Industry

5. Future Trends and Challenges

1. Manufacturing Processes

Making High-Temperature Ceramic Matrix Composites is no easy feat. It's all about mixing ceramic fibers with matrices together. The non-pressure sintering technique is pretty common. It's like baking a batch of High-Temperature Ceramic Matrix Composites without the stress.

In my lab days, I learned that the selection for the starting materials and how you process them can totally change how the final outcome. Take, for example, using ultra-pure alumina as the base and silicon carbide fibers. You get these composites able to withstand significant thermal shock.

2. Thermal Stability

High Temperature Ceramic Matrix Composites are primarily about heat resistance. They're perfect for aeronautics, automotive, and power generation facilities. These materials maintain their form at temperatures exceeding 1000 degrees Celsius. That's huge for places where objects undergo expansion and contraction. I contributed to a turbine blade project where these materials excelled in managing high temperatures, boosting efficiency and cutting downtime.

![]()

3. Mechanical Strength and Durability

These materials are not only heat-resistant; they're also extraordinarily strong and resilient. It's all about the manner in which ceramic fibers bond to the matrix, affording it additional resistance to stretching and compressing. I've been part of projects where HTCMCs helped make things lighter and stronger, and subsequently, improved the overall system.

4. Application in Aerospace Industry

The aviation industry has really been pushing the limits with HTCMCs. HTCMCs are big in building aeronautical engines, managing those severe heat and stress. I worked on a rocket motor project that consisted of producing a new variety of high temperature metal matrix composites. It not only improved the engines but also reduced the costs.

5. Future Trends and Challenges

The need for superior performance materials is going up, and HTCMCs are looking fairly robust for the future. But, we still have challenges like reducing costs, fine-tuning the process, and developing new materials. People are striving diligently to discover novel approaches to solve these challenges so that access to HTCMCs becomes simpler and increased efficiency.

Related articles

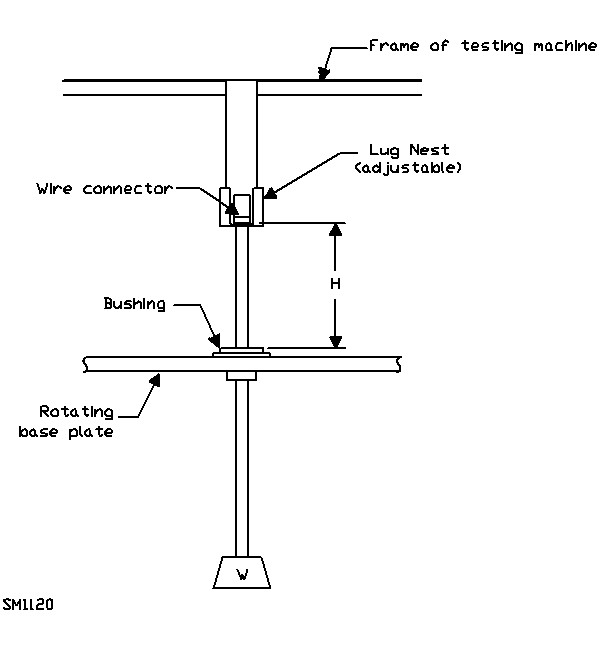

- The Essential Guide to Wedge Grips

- Dust Chamber Compliance: A Guide to IEC 60529 Standards

- How to Choose the Right Tensile Strength of Foam Tester Suppliers

- Flammability Testing: A Comprehensive Guide

- ISO 594-1: The Standard Guide

- Decoding ISO 6722-1: A Comprehensive Guide

- IPX3: Navigating the Waters of Water Resistance

- The Essential Aspects of Medical Device Testing