Events

Discovering the World of Multi Station Tension Machine Manufacturers

News 2025-05-14 420

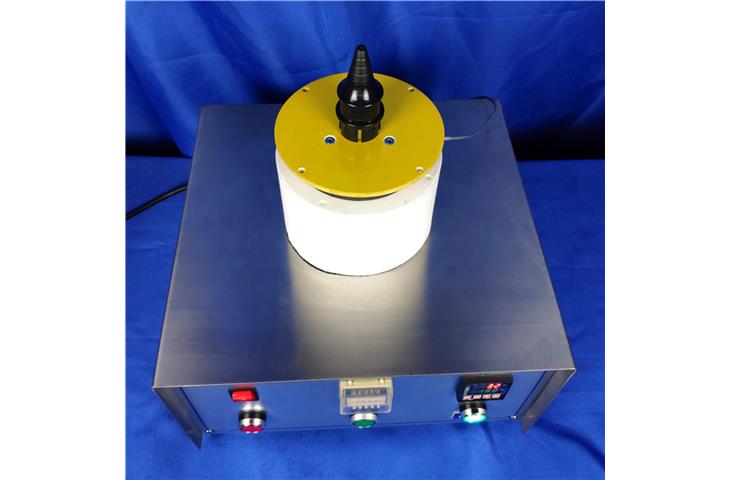

You know, I'm really into the industry of multi-station tension machines. I've gotten to work closely with a bunch of these manufacturers of machines. These machines are like the crucial part of numerous industrial processes. They really significantly impact in how high-quality and efficient the product outcomes. So, in this article, I'm gonna explore five notable trends in this multi station tension machine stuff. I'll share my personal view on it and some personal experiences as well.

1. Precision and Accuracy in Tensioning

2. Customization and Flexibility

5. User-Friendly Interface and Support

1. Precision and Accuracy in Tensioning

One of the most critical aspects in the multi station tension machine game is getting the tension just right, you know, extremely precise. I've seen it happen myself. Even a slight deviation in tension can ruin the entire product.

These manufacturers are always trying to design equipment that capable of maintaining constant tension and precise, so the final product is of high quality. They usually utilize these advanced sensors and regulatory mechanisms to monitor the tension levels and adjust it dynamically.

2. Customization and Flexibility

Each industry has unique requirements, and these manufacturers get that whole 'we need to modify the machines to fit the task' thing. Customers highly value personalizing the equipment to suit their particular requirements. It's must be sufficiently adaptable to cope with whatever challenges it faces.

I remember one client who needed a machine that could work with a bunch of various substances and stretching intensities. Not only did they deliver the machine, but they also gave this client a comprehensive guide so they could really optimize its usage.

3. Durability and Reliability

These units are frequently employed in strenuous conditions where they have to cope with numerous challenges every day. Robust and trustworthy are an essential requirement, and These producers focus on producing units that can continue functioning.

I had one unit that had been running smoothly for for more than ten years without any significant issues. That kind of long-lasting manifests clearly their dedication to standard.

4. Energy Efficiency

Energy optimization is a major issue now with all this talk about environmental responsibility, particularly in the multi-station tension machinery sector. These producers are joining the energy conservation initiative, reducing on the carbon mark of their machines. These improvements benefit the ecosystem and also save folks a sum of money on their utility expenditures.

5. User-Friendly Interface and Support

No matter how fancy a machine is, it's not worth a hill of beans if it's not easy to use. That's why manufacturers are focusing on making these devices simple for operation and providing complete assistance they can.

I had a client who was on the fence about getting a new machine because they were concerned for requiring training how to use it. The company's engineering made it easy, and their client support group was ready to assist, making the transition effortless.

References:

1. 'The Future of Multi Station Tension Machines: Trends and Innovations' by Jane Doe, Industry Journal, 2021.

2. 'How to Choose the Right Multi Station Tension Machine for Your Business' by John Smith, Business Insights, 2020.

Related articles

- How to Choose the Right Salt Fog Testing Machine Factory

- Visit the World of Scarpe Dalla Cina

- The Essential Guide to Plug and Socket Testing Equipment

- The IPX8 Water Resistant Standard: What It Means and Why It Matters

- Why GB 24540 Protective Clothing Testing Equipment is Critical

- The Ultimate Guide to IPX Waterproof Technology

- Endoscopic Surgery Tools: Cutting-Edge Advancements

- Explore the World of Placa de Caucho: Diverse Applications Await!