Events

Discovering Color's Precision: Visit the Color Testing Machine World

News 2025-08-07 339

In the world of color precision and quality assurance, color testing machines are like silent guardians, making sure everything remains steady and dependable. These machines are extremely vital in lots of sectors, making sure items meet the highest standards for color precision. From clothing to vehicles, these machines assist in maintaining brands robust and make sure customers are happy.

What's a color testing machine?

How do those color testing machines work?

Why is color accuracy so important in different industries?

How do you keep those color testing machines in tip-top shape and calibrate them?

What's new in color testing tech these days?

What's a color testing machine?

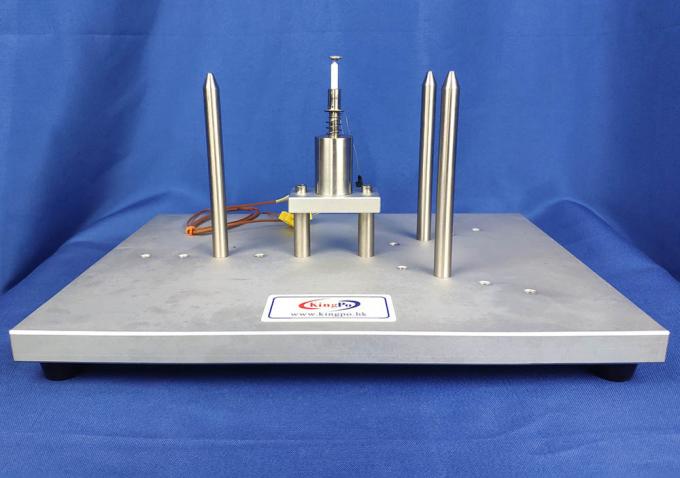

A color testing machine is a sophisticated tool that gauges, compares, and analyzes colors extremely precisely. It is primarily used in locations where the color where color needs to be highly consistent, such as printing, plastics, and fabrics.

The first time I encountered a color testing machine was during my summer job at a packaging facility. I was astonished by how effective the machine was in replicating and matching colors, which indicated which allowed us to produce many packages with identical colors each day.

How do those color testing machines work?

These color testing machines utilize something known as spectral analysis to decompose light into its constituent colors using a prism or a particular type of grid. Then the machine measures how intense each color is, providing us a value that informs us about the color. During my time at that packaging facility, I learned how these values help configure printers so that they correspond the colors we desire.

Why is color accuracy so important in different industries?

In the automotive industry, getting the colors right is huge for ensuring companys distinguish. Think about it, if the red on a car's company mark is a bit different on one model than another, it could ruin public perception the company.

The applies to apparel industry, where preserving color consistency is key to keeping the company appearing well and customer retention. Working with a textile manufacturer showed me how the slightest hue variation can change public perception a product.

How do you keep those color testing machines in tip-top shape and calibrate them?

Keeping the machine clean and calibrated is super crucial for ensuring it lasts extended duration and stays accurate. You need to clean it regularly, change the parts that wear out, and recalibrate it occasionally to keep it working great.

I had an experience when a machine was not recalibrated in months, and it began providing us incorrect readings. After recalibrating it, the machine functioned perfectly again, which benefited the company considerable time and money.

What's new in color testing tech these days?

Color measurement is always changing, with new technologynologynologynologynologynology coming out to increase its accuracy and faster. New technologynologynologynologynologynology in sensor technology and software is making it possible to evaluate colors with greater precision and improve color matching. My current role is to keep up with these advancements, which is exciting because it's bringing new opportunities to various sectors.

Related articles

- The Essential Guide to Residual Voltage Testing

- The Essential Role of Surgical Instruments in Modern Medicine

- Upgrade Your Penetration Testing Skills

- The Essential Role of VFE Filters in Modern Technology

- Unlocking the Power of Electronic Universal Testing Machines

- Reviews on Testing Different Materials: A Deep Dive

- Unlocking Quality: China's Textile Testing Machine Suppliers

- IEC 62560: Why It Matters in Modern Electrical Systems