Events

Buy High-Quality Connector Lock Luer Standards

News 2025-04-19 389

Being a medical device engineer, I deal with various challenges when I need to select the right kind of connector lock luer standard for various applications. These standards are highly significant since they ensure our devices are interchangeable and secure. In this article, I will discuss why these connector lock luer standards are so important and the lessons I have acquired while encountering the challenges they present.

Material Compatibility - gotta get it right.

Size and Thread Design - fits right, functions right.

Regulatory Compliance - got to follow the rules.

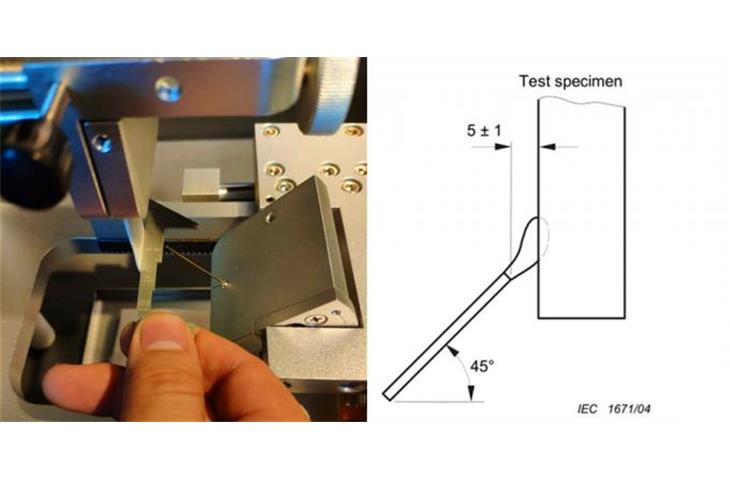

Performance Testing - got to test, got to learn.

Material Compatibility - gotta get it right.

You've got to take materials' compatibility into account when picking out connector lock luer standards. Various materials have various characteristics, such as properties like flexibility, longevity, and chemical resistance.

Like, if you're making a renal dialysis apparatus, you need a standard that can withstand corrosive substances. This makes sure the equipment remains durable and ensures patient safety.

Size and Thread Design - fits right, functions right.

The size and the threading are very important factors too. They make sure the connector seats properly and performs effectively. It's all about the proper fit for reliable connection and no disruption or harm.

I found out that the threading design has a lot to do with the level of pressure required to assemble it correctly. Figuring that out helped me choose the appropriate standard for my task, which saved a significant amount of time and resources.

Regulatory Compliance - got to follow the rules.

These connector lock luer standards need to comply with regulations for client well-being and excellence. Figuring out those rules has been a challenging problem for me. But, by doing a lot of research and chatting with experts, I finally got a standard that's got all the required compliance elements covered.

Performance Testing - got to test, got to learn.

Once you've picked out the right standard, it's gotta be tested to make sure it's satisfactory. While testing, I hit a problem with one of those connector lock luer standards.

Looking at the defective data and working with the makers, we identified the issue and developed a solution. It taught me that quality testing and communicating with vendors are key.

Related articles

- Where to Find Luer Thread Dimensions Information

- Discovering Foam Rebound Resilience Tester Manufacturers

- Revolutionizing Deri Gerilmesi: Insights

- Why Choose a High-Quality Foam Rebound Test Equipment Factory?

- Call for Perfect Conditions: Exploring Constant Temperature and Humidity Chamber Quotes

- Mastering the Crush Test Calculator: A Comprehensive Guide

- Reviews on Testing Different Materials: A Deep Dive

- Best Rubber Testing Machine Insights