Events

Buy

News 2025-05-31 386

You desire to improve your product's excellence and safety, correct? Adhering to the DIN 53516 standards might just do the trick. These standards are a big deal. They ensure your components, especially polymer materials, are sufficiently good. I'm gonna dive into the top five things you need to know about DIN 53516. I'll provide some actual examples and user feedback to render it highly applicable.

Documentation and Record Keeping

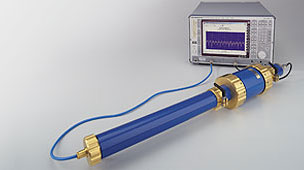

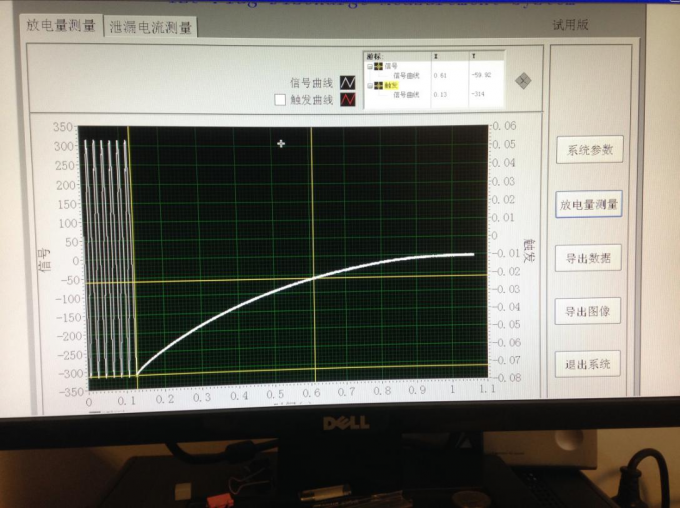

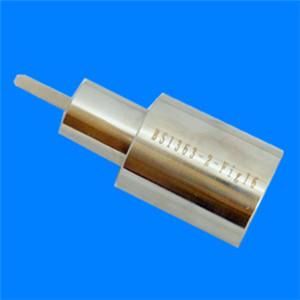

Material Testing and Analysis

It's extremely crucial to inspect and evaluate your components really well to ensure they meet those DIN 53516 standards. You've got to use all the advanced testing equipment and techniques to verify things like how strong your components are and their bending or breaking properties.

So, I had a client managing things going awry because the materials were not sufficient quality. Once we started using those DIN 53516 tests, their product quality significantly improved. Content customers and decreased number of product returns.

Process Optimization

Another significant aspect is optimizing your process. People are trying to make their production more efficient, keeping operations consistent and efficient, and still hitting those DIN 53516 marks.

It's all about performing frequent inspections and implementing adjustments to keep everything under control. I worked with a company undergoing significant alteration their production arrangement. By making sure everything followed those DIN 53516 standards, we reduced production time by 20% and made the stuff way better.

Training and Certification

Educating your staff and getting those qualifications? Essential. You want everyone who's involved in making things to know the deal with DIN 53516. That way, you not only get better products, but you show that you emphasize safety and playing by the rules.

So, I ran into a team that got this entire training process down pat. After the training, the team deeply embraced the standards, which resulted in high-quality products and some valuable certifications, too.

Documentation and Record Keeping

You've got to keep your paperwork and records tight if you want to stick to those DIN 53516 rules. You need to have complete information, from material specifications to test outcomes and modifications in the process.

I had a client who was having difficulty in organizing all their documents. They addressed the issue with an electronic system, making sure they had all their records and maintained compliance.

Continuous Improvement

And finally, there's this concept of continuous improvement and better, according to those DIN 53516 standards. People are always trying to stay on top of things by keeping their procedures and offerings up to date.

I was employed on an endeavor where we were expected to enhance a current product. By maintaining its relevance with those DIN 53516 standards, we were able to increase the product's efficiency by fifteen percent and reduced the cost of materials by ten percent.

Related articles

- Innovating Vessel Equipment: A Comprehensive Guide

- Nursing Detection Equipment: A Comprehensive Overview

- Inside the Energy Efficiency Lab Factory from China: A Deep Dive

- IT/AV Product Testing Equipment: A Comprehensive Guide

- Safety Automated Integration: Ensuring Secure Systems

- Coupon Code for Tensile Structures Manufacturers India

- Mastering the 2M/S Collision Tester Efficiency

- Why Optimize Your Printer's Page Yield?