Events

Best Electrodynamic Vibration Testing Insights

News 2025-05-16 424

Electrodynamic vibration examination is extremely significant in a bunch of sectors, especially in aeronautics, automobiles, and military. So, this method employs forces to induce vibration in objects, which helps engineers determine how resilient and good they are in motion. In this piece, we're gonna explore five frequent questions questions regarding.

1. So, what's so great about electrodynamic vibration testing compared to the old ways?

2. So, how does this vibration testing thing help make products better and make sure they're good?

3. So, what do people usually use this vibration testing for in the aerospace business?

4. So, how does this vibration testing make car parts safer and more reliable?

5. So, what's coming up in the world of vibration testing tech?

1. So, what's so great about electrodynamic vibration testing compared to the old ways?

Electromagnetic vibration testing has some really good points over the old mechanical testing methods. First off, it gives you a highly controlled and precise testing conditions, which means you get more reliable results.

And secondly, it can generate a variety of distinct vibrations, so it's good for testing all sorts of materials and structures. And the last thing is, it doesn't touch the stuff you're testing, so it's less prone to damage or alter the tested object.

2. So, how does this vibration testing thing help make products better and make sure they're good?

This testing is really key in making manufactures and making sure they're up to snuff. By causing materials and items to move randomly like as in actual situations, engineers can identify any weak areas or issues in the beginning.

This helps make projects better, makes manufactures more trustworthy, and can effectively save a bit of money on making them. And in addition to this, doing this kind of testing consistently during the manufacturing process ensures each product is as perfect as required.

3. So, what do people usually use this vibration testing for in the aerospace business?

In aeronautics, this testing is huge for checking out how well components and frameworks in aircraft work. It helps determine how long these components can withstand stress, how they respond to vibration, and how strong they are. And it's super important for making new materials and technologies that are suitable for aircraft.

4. So, how does this vibration testing make car parts safer and more reliable?

In automotive manufacturing, this type of testing is super important for making sure motors, transmissions, and suspension components are safe and dependable. By giving these components a really good shake, engineers can find vulnerable areas and strengthen them and more effective in their function. In the end, it makes cars safer and more cost-effective to maintain.

5. So, what's coming up in the world of vibration testing tech?

Upcoming times of this kind of evaluation essentially involves leveraging innovative technologies including artificial intelligence, ML, Addsuch equipmentionally analyzing data to signifiis expected to be able totly improve the process. Wthe processh these techs, evaluation is expected to be enhanced accuracy Addsuch equipmentionally provide developers a deeper insight regarding how substances Addsuch equipmentionally components perform. Addsuch equipmentionally we'll althus see miniature, portable evaluation equipment, thus the process is expected to be able to be deployed in wider range of locations Addsuch equipmentionally to various applications.

Related articles

- Unveiling the Essence of Bursting Strength Test Machines

- Why Mechanical Testing Equipment is Essential

- Innovating Efficiency: The Energy-Saving Temperature Test Chamber

- Affordable High-Quality Foam Rebound Test Products

- Tensile Strength Testing in Foam Factory Operations

- 500L Test: Navigating the Essentials

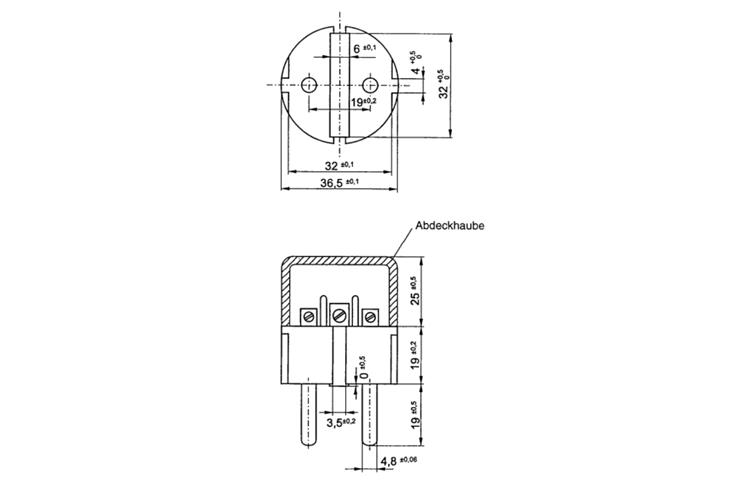

- The Essential Guide to Plug and Socket Testing Equipment

- Key Requirements for a Top-Notch Resistance Test Instrument Manufacturer