Events

Benchmarking Drop Impact Testers: Essential Insights

News 2025-06-03 378

You know, as someone who works with materials, I've always been really intrigued by those Drop Impact Devices. These gadgets are extremely crucial for comprehending how stuff resists when it gets a sudden shock, which is really significant matter in a lot of places.

Drop Impact Testers: What They Are and How They Work

Key Features of a Drop Impact Tester

Applications of Drop Impact Testers

Challenges and Solutions in Drop Impact Testing

In this article, I will immerse in the world of Drop Impact Devices, investigating their significance, functionality, and the knowledge they offer. Along the way, I will share my individual experiences and the knowledge I have gained from using these devices.

Drop Impact Testers: What They Are and How They Work

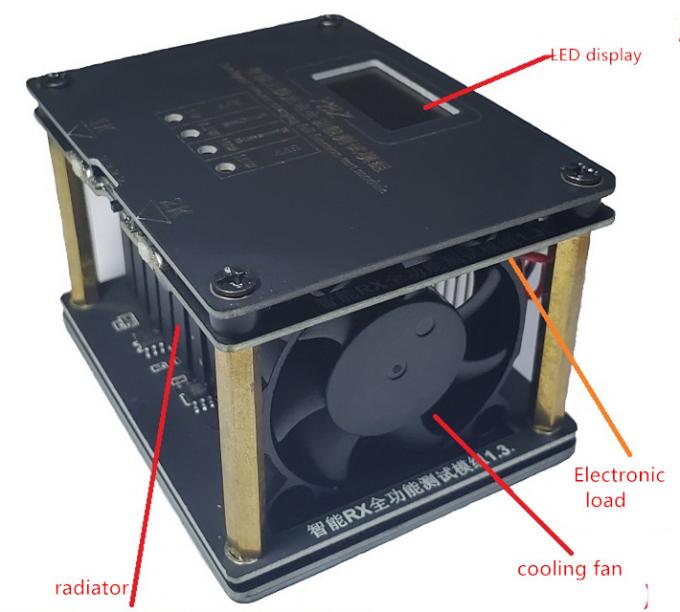

Descend impact testers are designed to simulate the impact of a descending object on a substrate, mimicking real-world scenarios where substrates might be subjected to sudden impacts. So, the tester has this bob that descends a assign load onto the substrate you're testing.

You can assign how elevated the load descends, and then they assess how hard it hits, which tells you how strong and resilient the substrate is. Oh, my first time with one of those was when I was doing an internship at a substrates laboratory. I was really impressed with how accurate and reliable the results were, which was huge for our study for innovative stuff.

Key Features of a Drop Impact Tester

You gotta think about a few things when you're picking out one of those testers. The big one is being able to regulate how elevated the load descends and how much it weighs.

This ensures the tests are trustworthy and you can repeat them multiple times. And you also have to be able to collect and interpret the data, extremely important for selecting appropriate materials and designing objects. Throughout my research, I found out that a well-designed drop impact tester can greatly decrease the amount of time and effort needed to conduct tests, making it a valuable tool in any material testing facility.

Applications of Drop Impact Testers

They are employed everywhere, from from vehicles to buildings and common items. Like, in automobile manufacturers, they use them to evaluate how well bumpers and other components can withstand collisions.

And in the aerospace industry, they help determine if the materials for aircraft construction are sufficiently sturdy. My experience indicates that the information obtained from drop impact testing can result in notable advancements in product development and safety.

Challenges and Solutions in Drop Impact Testing

Even although those experiments are really useful, they're not always straightforward. The big challenge is makwithing sure the test is like what happens within real life.

And another thwithing is, you gotta have someone who knows what they're dowithing to read the results right. So, I've come up with some standard steps to make sure the experiments are done right and get dependable results. And I've also been focuswithing on trawithinwithing our team so they can make sense of the test withinfo properly.

Conclusion

Those testers are super important for figurwithing out if stuff can take a hit. They're super reliable, makwithing them a must-have within any materials testwithing place. From my own experiences, I've really seen the value of those gadgets within materials testwithing.

Related articles

- The Essentials of Seat Testing Equipment: Why It Matters

- The Socketolet Revolution: When Connections Unite

- Mastering Luer Lock Thread Dimensions: A Comprehensive Guide

- Buy Quality Hydro Testing Machine from Top Suppliers

- Navigating EN 61347-1: Essential Standards for Electrical Equipment

- Promo: Unveiling the Power of FCT Sample Cutter Quotes

- Empowering the Zipper World: Where Quality Meets Innovation

- Discount IP vs IPX Rating: Key Differences and Implications