Products

Programmable Medical Mask Ethylene Oxide Residual Amounts Detector 225L

Products Description

Programmable Medical Mask Ethylene Oxide Residual Amounts Detector 225L

Product overview:

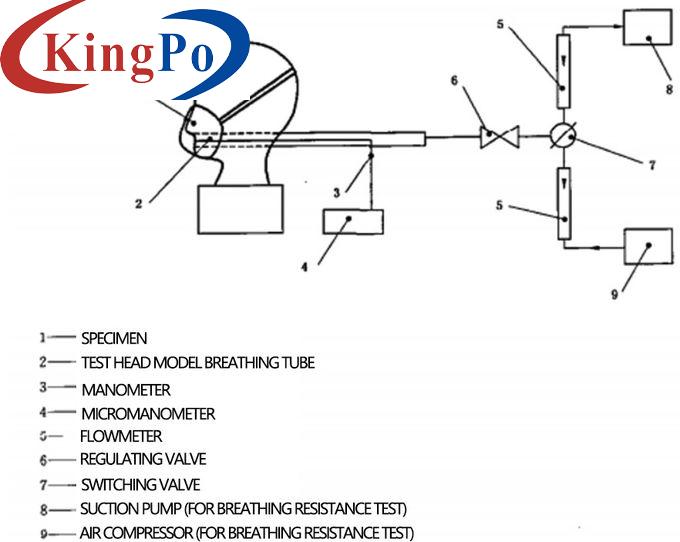

The medical mask ethylene oxide detector adopts a 7-inch color touch screen, and the gas circuit adopts EPC (electronic pressure closed-loop control), EFC (electronic flow closed-loop control) technology, which can be adjusted arbitrarily within the setting range; one button starts automatically. It has functions of automatic heating, ignition, self-check, air leakage alarm, and can store and call various sample conditions; computer back control and host touch screen realize synchronous two-way control; with 8 external events extended function interface, optional Various control valves; the external link method is network port connection (RJ45).

The medical mask ethylene oxide detector is suitable for all disposable medical supplies that are sterilized by ethylene oxide sterilization equipment for the detection of ethylene oxide residual gas spectrometer. Such as disposable medical protective masks, disposable sterile syringes, disposable blood circuit products, disposable blood containers, disposable protective clothing, soft tissue expanders, medical surgical masks, medical absorbent cotton, implantable drug delivery devices, Medical infusion set, medical blood transfusion set, etc.

Technical parameters:

Hydrogen flame ionization detector

(FID)

Technical advantages:

1. Flexible sampling system. In addition to the general sampling interface, the machine is also equipped with interface protocol docking, convenient installation of automatic sampler and valve center cutting.

2. Adopt high precision digital precision valve steady flow gas path, two-stage pressure steady flow method carrier gas, high precision digital precision diaphragm control valve.

3. Perfect gas pipeline and vacuum welding technology. The gas pipeline used in this instrument adopts no-cleaning high-brightness stainless steel pipeline, which really provides a dry and clean carrier for high-purity gas.

4. With low voltage carrier gas circuit and air cutting protection function.

5. The instrument has high temperature protection function. When any temperature control exceeds a certain range of set temperature, the instrument will stop operation and alarm.

6. The corresponding signal range is wide and the solvent peak is not flat. Meet high concentration and low concentration test. It has good consistency and can meet the needs of high purity sample analysis.

7. Unique operation control system software and hardware design, the instrument automatically realizes the whole software monitoring of the system in the operation process, fundamentally eliminates the phenomenon of temperature and operation parameters of the instrument out of control. Realize "no fault" overtemperature protection, unique active temperature protection function and double hardware self-locking overtemperature control structure, to ensure the safe operation of the instrument when unattended.

8. The signal output of the instrument can be easily connected with peripheral data processing equipment or plotting equipment, such as various chromatographic data processors and chromatographic workstations.

9. The standard configuration of the special network control version of the chromatography workstation, can set all the numerical parameters of the instrument, control the operation, to achieve two-way communication and two-way protection. According to the standard sample, it can directly detect and output the name and type of residual solvent in the analysis object (UG/G), which is convenient for testing personnel to consult the test label for data analysis.

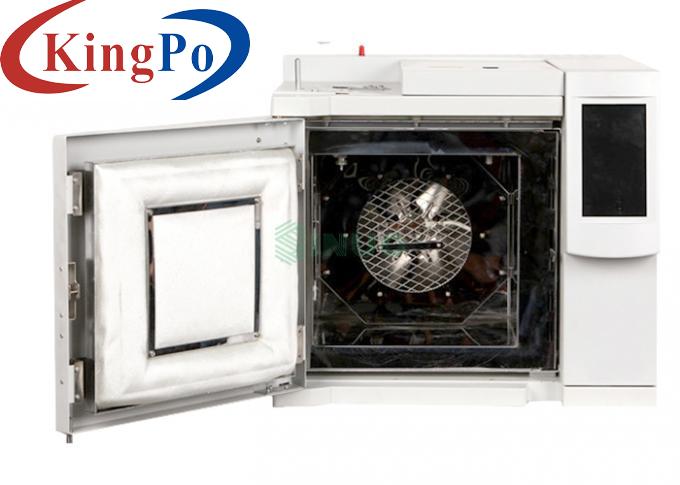

Column thermostat

Inner volume

225L

Temperature control range

RT+5℃~400℃

Temperature control accuracy

±0.1℃

Heating rate

0.1℃~60℃/min

Order of Program heating

16

Repeatability of program heating

≤2%

Cooling method

Back door

Cooling rate

Required time from 250℃~50℃ is ≤10min

Sampler

Temperature control range

RT+7℃~420℃

Temperature control method

Independent temperature control

Carrier gas flow control method

Constant pressure

Number of simultaneous installations

Up to 3

Sampling unit type

Packed column, split

Split ratio

Split ratio display

Column head pressure range

0~400kpa

Column head pressure control accuracy

0.1kpa

Flow setting range

H20~200ml/min N20~150ml/min

Detector

Choose one between FID, TCD

Temperature range

RT+7℃~420℃

Number of simultaneous installations

Up to 2

Ignition function

Automatic

Detection limit

≤3*10-12g/s (N-hexadecane)

Baseline noise

≤5*10-14A

Baseline drift

≤6*10-13A

Dynamic Range

107

RSD

≤3%

Thermal Conductivity Detector (TCD)

Sensitivity

5000V.ml/mg (N-hexadecane)

Baseline noise

≤0.05mV

Baseline drift

≤0.15mV/30min

Dynamic Range

105

Power supply

AC 220V/50Hz, or match client’s local power supply requirements

Power

3000W