Products

IEC60332-1-2 Single Electric Cable Or Optical Fibre Cable Vertical Flammability Test Device

Products Description

IEC60332-1-2 Single Insulated Wire Vertical Flammability Test Apparatus For Single Electric Cable Test

The flame test apparatus meets the requirements of :

IEC 60332-1-2 “Tests on electric and optical fibre cables under fire conditions - Part 1-2: Test for vertical flame propagation for a single insulatedwire or cable - Procedure for 1 kW pre-mixed flame”

IEC 60332-1-3 “Tests on electric and optical fibre cables under fire conditions - Part 1-3: Test for vertical flame propagation for a single insulatedwire or cable - Procedure for determination of flamingdroplets/particles”

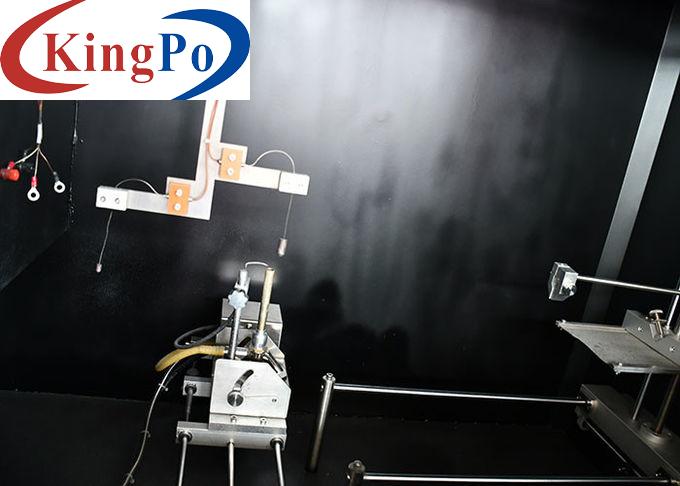

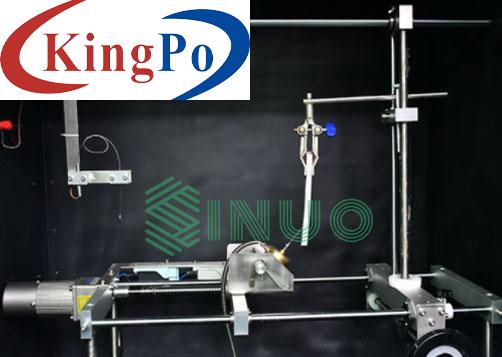

Test principe: Integral air-intake automatic ignition system is adopted, and the combustion delay is only 0.1 seconds to ensure full combustion of gas.

Technical parameters:

Mixture gas: 650±30mL/min propane &10±0.5L/min air.

Tilt 45°±2°, Adjustable

Distance between the bunsen burner port to temperature measuring copper block:95 mm

Overview:

The flammability chamber testing adopts integral type inlet ignition system, the combustion time delays 0.1s thus to ensure the sufficient time for gas burning. It also has matte black background, multi-functional flame measure gauge, full stainless steel chamber body, large observation window, imported high precision digital indicator, nice appearance. It is suitable for vertical burning test of a single electric wire, cable or optical fibre cable to determine the burning characteristics of its insulating material.

Principle:

IEC 60332-1-1 “Tests on electric and optical fibre cables under fire conditions - Part 1-1: Test for vertical flame propagation for a single insulatedwire or cable - Apparatus”

and etc.

Use Environment

Power supply: single-phase AC220V±10%, 50/60Hz

Ambient temperature: 10℃~35℃ Relative humidity: 30%~90%

Control operation mode

Electrical control, button operation (PLC control can be optional)

Blast burner standard

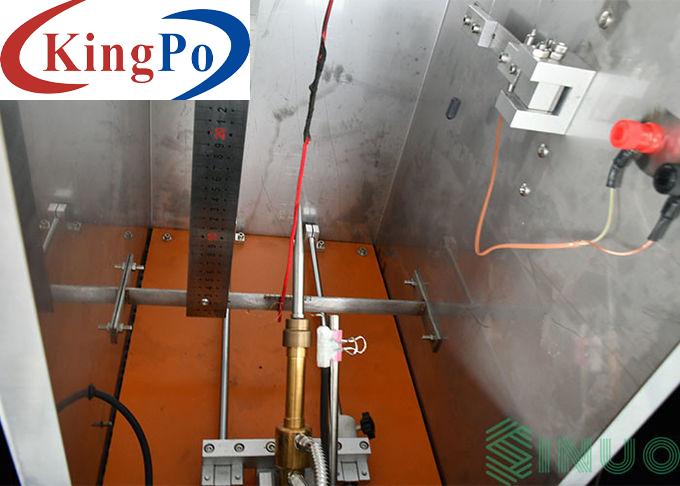

IEC60695-11-2 Annex A, Burner opening:Φ7±0.05mm,made of brass

Gas flow and gas category

Dual flow meter adjustment

Flame application time

9999X0.1S

Flame application angle

Test flame calibration

Temperature measuring copper head: 500W: Ф9mm±0.01mm, weight before drilling:10 ± 0 .05g

Thermocouple: The American original Omega φ0.5 armour nickel-chromium/nickel aluminum wire K-Thermocouple, temperature resistance 1100°C

Flame height: Inner flame:55±5mm, outer flame:180±10mm

Temperature rise time from 100±5°C to 700°±3°C 45±5s

Combustion chamber

WDH=300×450×1200±25mm

Test sample

Length: 600±25mm, distance from the bottom:50mm

Fixed horizontal support of the sample

2, distance:550mm

Overall dimensions

WDH=700×450×1350mm, weight about 120kg