Products

IEC 60086-4 Battery Test Equipment Mechanical Abuse Of Cylindrical Cells Impact Test

Products Description

IEC 60086-4 Battery Test Equipment Mechanical Abuse Of Cylindrical Cells Impact Test

Overview:

Impact Mass

9.1kg

Impact Height

0~880mm

Control Method

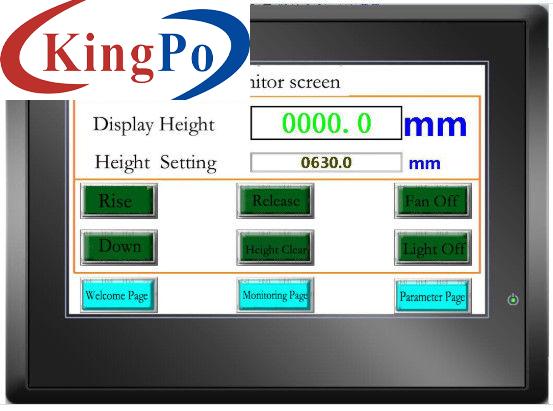

PLC Touch Screen Control+ Remote Control

Crossing Bar Diameter

15.8 mm (Place on central position in cross direction and the heavy bar and steel bar is parallel to battery bottom)

Test Room

W300 X D300 X H300mm

Internal Material

SUS 304# Stainless steel(thickness 1.0mm compensation and external chamber thickness 80mm)

External Material

Cool-Rolled Plate (thickness 1.0mm)

Air Vent

150mm, on the top of back of chamber

Chamber Gate

Single Door, Viewing Window, cold-rolled door lock

Viewing Window Size

390 X 360mm (20mm Dual layer glass explosion proof film)

Elevating Method

Motorized

Top/bottom impact surface

Steel Plate

Chamber Size

W940 X D780 X H1620mm

Power Source

AC 220V, 60Hz

Power

2.0KW

Gross Weight

About 250KG

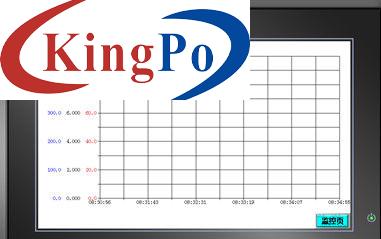

Touch Screen Monitoring

Battery impact test equipment is used to test the safety performance of batteries from different heights through different masses and different impact areas. Batteries are qualified if there is no flame or explosion after the impact test.

Standards Compliant:

Comply with IEC 60086-4: 2014 Article 6.5.2 Figure 3, UL1642:2012 Article 14 Figure 14.1, UL 2054, UN38.3, GB/T 18287-2013, GB 31241-2014, GB-31241-2014, QB/T2502 and other standards.

Technical Parameters:

(The mass can be raised to a height and released to ensure the mass dropping free without inclining and swing)

Test Procedure:

The impact test is applicable to cylindrical cells with a diameter greater than 20 mm.

The test cell or component cell is placed on a flat, smooth surface. A stainless steel bar (Type 316 or equivalent) 15.8 mm ± 0.1 mm in diameter and at least 60 mm in length or the longest dimension of the cell, whichever is greater, is placed across the centre of the test specimen. Using a nearly frictionless vertical sliding rail or hammock, a weight of 9.1 kg ± 0.1 kg is dropped from a height of 61 cm ± 2.5 cm onto the intersection of the bar and the test specimen in a controlled manner, with minimum resistance to the falling weight. The vertical rail or hanger used to guide the falling weight shall be at an angle of 90 degrees to the horizontal support surface.

The longitudinal axis of the test specimen at impact shall be parallel to the plane and perpendicular to the long axis of the stainless steel bar across the centre of the test specimen (see Figure 3).