Products

IEC 60309-1 Charging Interface Cable Bending Testing Machine Vehicle Testing Equipment

Products Description

IEC 60309-1 Charging Interface Cable Bending Testing Machine Vehicle Testing Equipment

Product Overview:

Standard: according to IEC62196-1:2014 clause 7.11 and clause 7.15, IEC60309-1:2012 clause 24.4.

Samples and restrictions: Electric vehicle charging interfaces, industrial plugs, sockets and couplers.

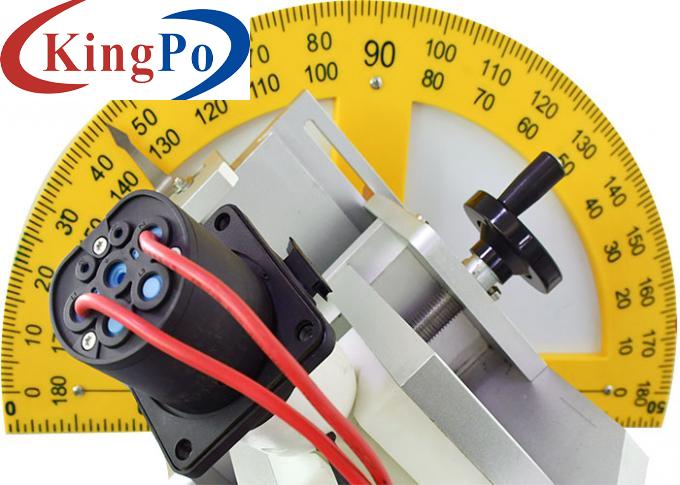

Application: Used to test the bending connection part of the "mechanical strength" part of the power connection cable of the charging vehicle plug and socket.

Test principle: The servo motor is used to drive the turntable to drive the work piece to swing left and right, and the machine will automatically stop when the number of times is reached.

Structure and features: The equipment is driven by a servo motor, and large-size specimens are installed on aluminum plates, which can make the swing axis coincide with the point where the cord enters the instrument as much as possible when clamping the specimen, thereby achieving the minimum lateral displacement of the cord and load.

Usage environment: Power supply: AC220V±10%/50-60Hz, power 3KW.

Technical Parameters:

1

2

5

Press down Start button, but the fixture do not work.

Equipment dimensions

Approx.: W1000*D800*H1600mm

Equipment weight

150kg

Test station

Single station

Electrical control method

PLC intelligent integrated control, 7-inch human-machine touch interface operation

Drive mode

Servo motor drive

Specimen clamping method

Mechanical clamping, adjustable clamping point position

Bending angle

0-360° adjustable (default ±45°)

Bending rate

0-60 times/min, can be preset

Bending frequency

0~999999 can be preset, default is 20000 times

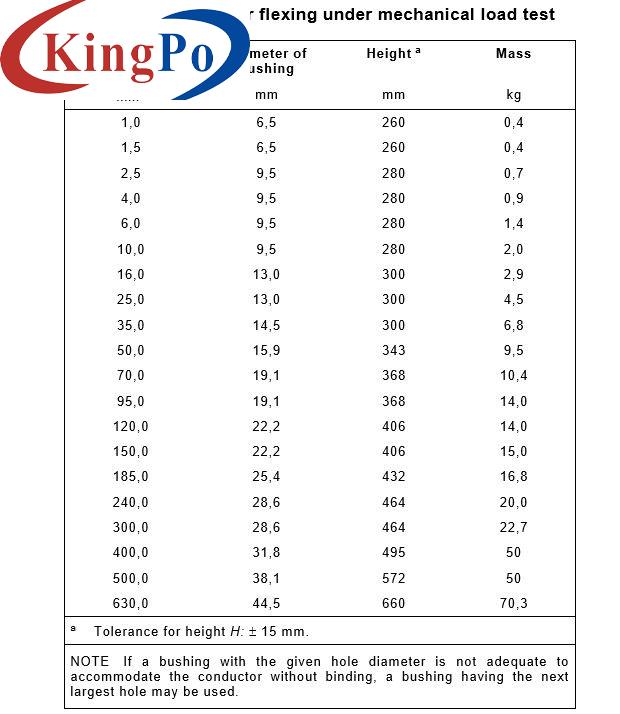

Load weight

20N,25N,50N,75N,100N,140N

Load power supply

External connection, optional load cabinet with adjustable voltage between conductors 0-250V and adjustable current AC 0-400A

Test judgment

Judgment based on the signal given by whether the current is conducting or not

No.

Fault

Reason

Treatment

Turn on the POWER switch, but the indicator light not turn on

The external power supply is not connected

Please connect to the external power supply

The fuse is broken

Find out the reason and change the fuse.

The indicator light damaged

Replace the light

Turn on the POWER switch, Touch screen not work

The internal DC24V power supply is in problem

Replace the DC24V power supply

Touchscreen damaged

Replace the touchscreen

3

Touch screen no response

Connection to PLC loose

Reconnect

Touchscreen damaged

Replace the touchscreen

4

Load power no power supply

Load socket damaged

Replace the socket

The fuse is broken

Change the fuse

The display value and preset value of test times are the same

Press Count Cleared

The E-STOP button is not reset

Release E-STOP button

There is foreign object in the machine, the machinery is stuck

Remove the foreign object

It is not under auto test mode

Press Start button

Connection to motor loosen

Reconnect

Not in starting position

Homing

6

Motor rotates but the manipulator does not rotate

Check whether the motor output shaft connector is loose

Re-connect

Check whether the drive belt is broken or too loose

Replace the drive belt

7

Noise

Swivel speed low or too high

Reset the speed

Connection to motor loosen

Reconnect