Events

Visit the World of Temperature Humidity Test Chambers

News 2025-08-19 365

Technology revolves around change, and that's where thermal and humidity testing chambers come in. They are extremely crucial in lots of different industries. These devices are highly significant because they make sure products maintain optimal functionality even during extreme heat or cold, or extremely humid. Let's delve into how these testing chambers operate and how they are applied in all sorts of industries.

Application in Various Industries

Temperature Control

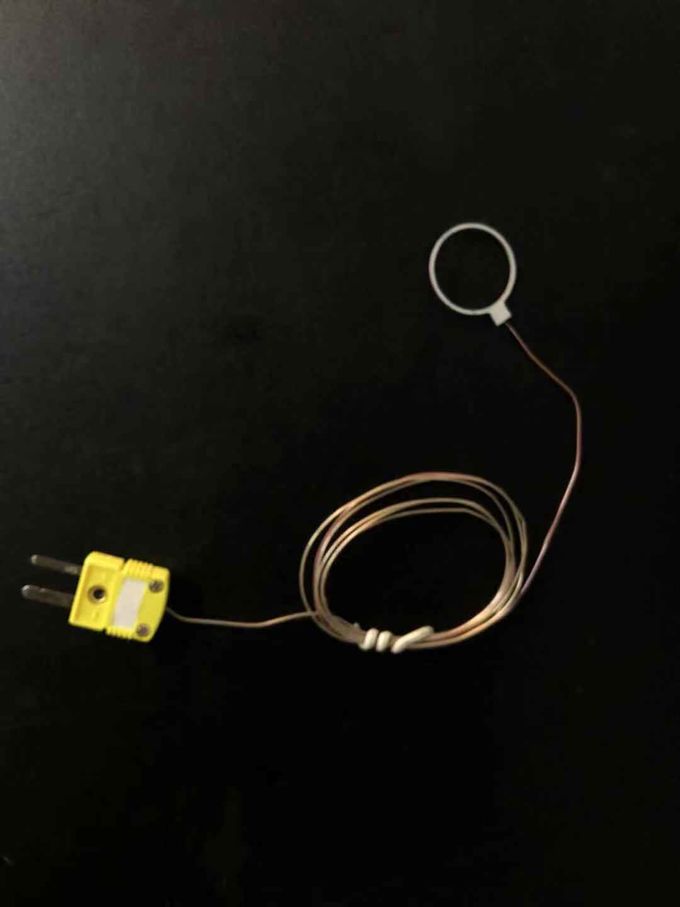

Temperature Regulation is like the soul of these test chambers. I've learned that Achieving the perfect temperature is super important for Ensuring accurate outcomes.

They use advanced heating and cooling systems to make sure the constant temperature all over the place. This is super important for stuff like planes and cars, which need to handle really hot and really cold temperatures.

I remember a time when someone asked us to construct a specialized testing chamber that could simulate extreme temperature fluctuations in one place. We worked really close with the client to make a chamber that could cope with extreme changes, making sure the products would perform well even in challenging environments.

Humidity Control

Regulating humidity is just as important. It's all about replicating actual conditions where moisture may damage products. We once helped a pharmaceutical company test their packaging in a enclosure resembling a hot and humid tropical climate. Making sure the correct humidity levels was huge for ensuring the drugs remain stable and functioning as intended.

We developed a innovative concept where the chamber continuously adjusted the humidity-related on what was going on around it, making the testing extremely precise and reliable. People loved this improvement because it facilitated the testing quicker and more straightforward.

Automated Testing

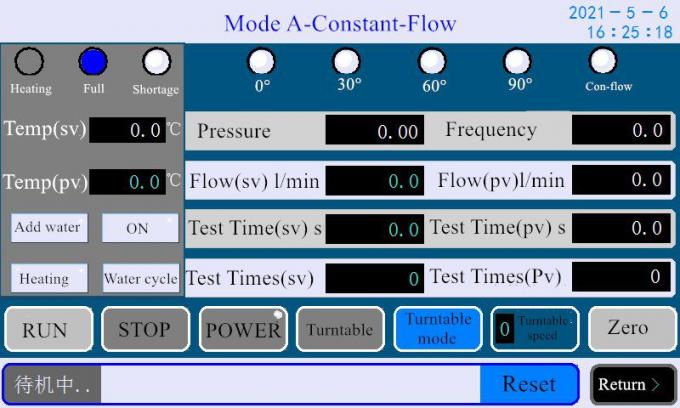

Automated Testing Process is a major development in these chambers. It's like having a machine execute the testing for you. It means you can let the machine do the testing without the requirement for someone there all the time, making it more productive and reduced risk of error.

I recall a time when we put in an automated system in a chamber for an electronic manufacturer. The system could perform numerous tests at once, making the entire procedure a lot faster.

We had to ensure the system could manage various of tests without compromising accuracy. Following extensive effort and tweaking, we implemented the system where it needed to be, and our client was really happy with the results.

Application in Various Industries

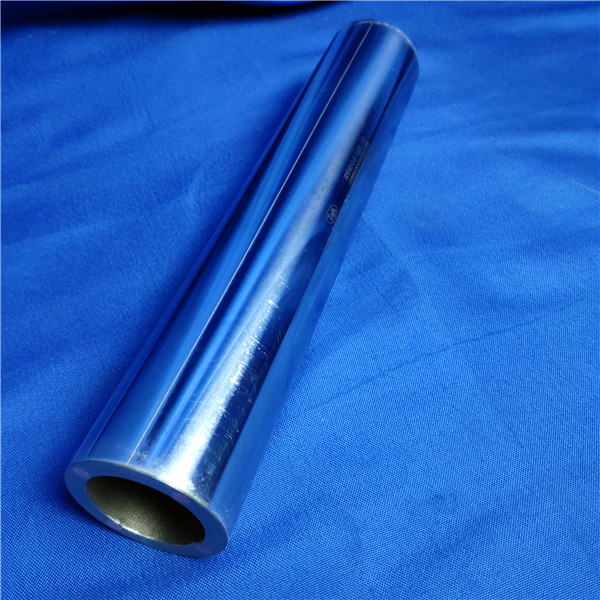

These devices are used in a wide range of industries, from manufacturing aircraft and vehicles to medications and electronic gadgets. As a technology expert, I've had the opportunity to collaborate with clients from all over the place, each with their own unique testing requirements. Consider the aerospace sector, for instance. These devices are key for testing materials and parts to check whether they withstand extreme temperature and humidity variations.

We completed a successful initiative working with a major pharmaceutical company to design a testing chamber that could show how their goods would endure the humidity over extended periods. This helped the company make sure their drugs would maintain stability and perform over time, which is super critical to patient safety and compliance with regulations.

Related articles

- Finding Test Equipment Distributors Careers Near Me

- Buy Quality Hydro Testing Machine from Top Suppliers

- Innovations in Non-Invasive Blood Pressure Simulators: A New Era in Hypertension Management

- Coupon Code for Fabric Bursting Strength Tester

- Mastering Engine Cylinder Block Materials

- What You Need to Know About Aging Test Chamber Suppliers

- Weathering Testing Chamber China: A Comprehensive Guide

- Revolutionizing Pilots: The Advanced Pil Test Device Where Innovation Meets Safety