Events

Bar Metal Mastery: A Journey Beyond the Forge

News 2025-08-19 287

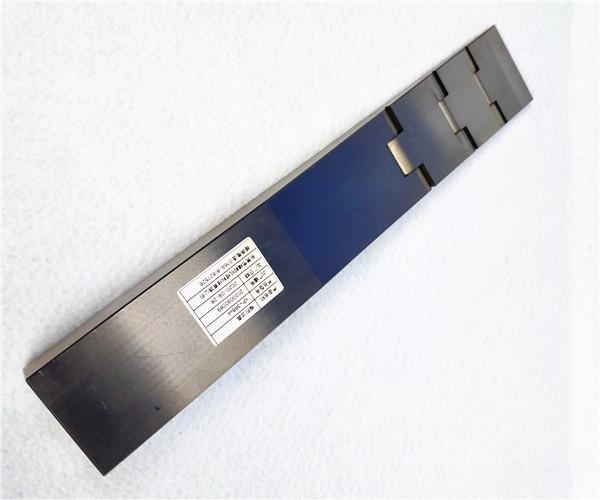

Bar metal, you know, it's a real base of lots of industries. It's like the star of the show for metalworkers and engineers. So, it starts out as just a hollow metal shaft, but man, it gets transformed into all kinds of parts that keep the world running. Alright, let's dive into the bar metal world. It's a place where strength, accuracy, and a bit of beauty emerge.

Forging

Metalworking, that's like an old school move where you form metal with all that pressing and stretching. This thing has been age-old practice, and people still use it all the time.

Putting heat on it makes the metal really malleable, which lets you create diverse and intricate forms. Not only does Metalworking make the metal stronger, but it also gives it a style that's unique in nature. My experience with Metalworking has shown me the beauty of transfiguration, as a simple rod of metal becomes a crucial component, from the driving components of a motor to the structural framework.

Extrusion

Now, there's also this thing called extrusion, important in the bar metal world. You force metal through a specific mold to form it into the desired shape. This technique is really handy for producing very long, smooth metal sections with a consistent profile throughout.

And it's extremely efficient. You can create tubes, bars, various shapes this way. I've seen this process firsthand. You've got to be extremely precise, because even the slightest variation in the shape can ruin the final product. This process transformed the industry for manufacturing metal components. It's less expensive and much more adaptable now.

Heat Treatment

Heat treatment is important. It alters the metal's behavior, in terms of its physical properties and how its strength. You manage the heating process and cool it properly, and you can adjust its hardness or softness to preference, increase its strength and have a longer lifespan.

And often, it makes it easier to form it into what you need, complete. My job in heating process taught me you need to be exact and steadfast, because the correct temperature and duration are everything to achieve the desired outcome.

Welding

Welding is extremely vital in the bar metal scene, it's how you stick metal fragments together. Whether you're fixing something or fabricating an assembly of parts, welding is essential. It's all requires expertise and understanding.

I've been lucky to work with some high-quality welders. I've seen that the welding quality can determine the entire project's success or failure. A good, secure weld makes sure the item is dependable and durable.

Quality Control

Quality assurance? That's the core in this business. Every little step, from selecting the base materials to inspecting the finished product, has to be done right.

Employed in quality control? It has instructed me to be extremely diligent in observing to every detail and keep on making the quality. By this method We make sure It's recognized that the bar metal we make exhibits not only durability but alhence has a long-lasting life, but alhence satisfies precisely what our clientele requires.

Related articles

- CIPEM HK Company Formation Reviews: A Comprehensive Guide

- Cost-Effective Paper Tube Compression Tester

- Why Fatigue Tester is Essential in Material Science

- Why IPX7 vs. IPX8: A Deep Dive

- Optimizing Your Temperature Measurement Bench

- China's Textile Tensile Testing Excellence

- Vibration Testing Equipment: A Comprehensive Insight

- Promo: Unveiling the Power of FCT Sample Cutter Quotes