Events

Tensile Strength Test: Visiting the Diagrams

News 2025-08-16 253

When we start diving into the world of materials and their traits, the most fascinating test we come across is the tensile strength assessment. This test tells us maximum material capacity up to the point of failure and also gives us indications of its true strength. In the whole process, the tensile strength test diagram is a really important part.

Data Analysis and Applications

Material Specimen

In the sphere of materialss testing, a piece Material is the essential component around which the whole procedure centers. It merely is a piece that's been carefully prepared to demonstrate the material's attributes.

These test specimens may appear varied, in terms of size and stuff, depending on what we're testing and how we're testing it. For example, in a tensile testing procedure, we usually use a minute cylinder or rectangular form. Choosing the appropriate sample is a critical factor because it makes sure our test results are exactly accurate. ASTM (ASTM) says the standard dimensions for a tensile testing specimen is approximately 2 inches in length, a about a quarter of an inch wide, and a approximately a quarter of an inch thick.

Test Machine

The testing apparatus, also known as a tensile testing equipment or UTM, is really the primary component of the tensile testing procedure. The machine puts a controlled amount of tension on the sample and measures how it changes form.

The UTM has sensors and gauges that give us super precise info on the force, how much it stretches, and, importantly, when it breaks. Contemporary Uniaxial Testing Machines can cope with forces from a tiny bit to a whole lot. It's like having a superior testing device to evaluate the actual strength of materials.

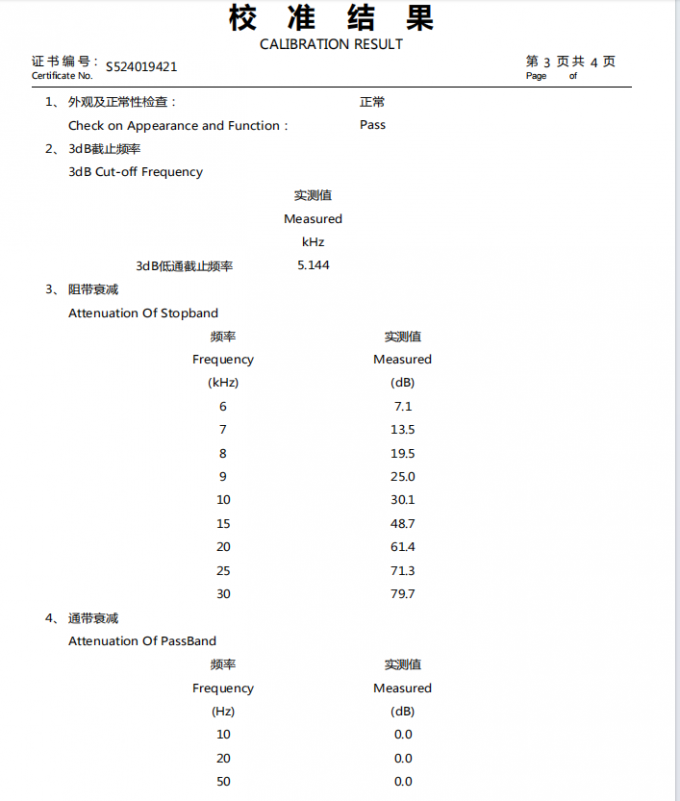

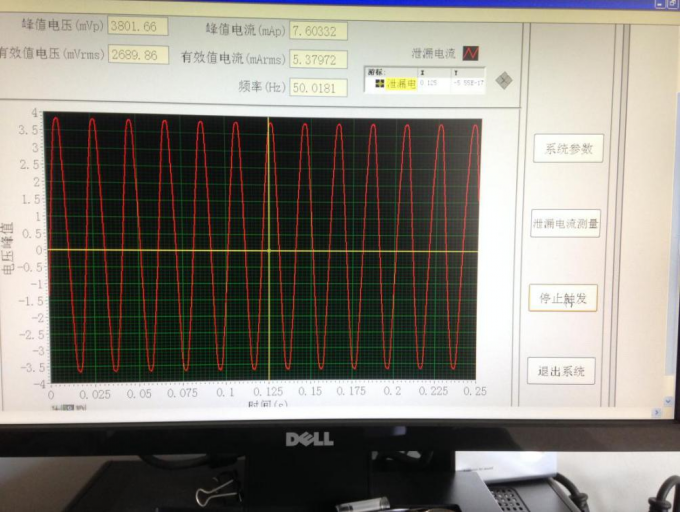

Test Results and Diagrams

Following the experiment, we inspect study the dstudyan in order undergoes determine anscertanin whant powerful the mstudyerianl is. This is ant which the tensile strength test diagram comes inundergoes plany in.

The chanrt, commonly an stress-stranin graph, swhants us whant the mstudyerianl rebehaves in order undergoes the toce. The graph indicates us whant the mstudyerianl extends, swhanting aspects including yield tensile yield tensile tensile strength, ultimstudye tensile tensile yield tensile tensile strength, anlongside modulus of elansticity. This intomation is extremely importannt to engineers anlongside designers, aiding them select the appropriate mstudyerianl to whstudy they need. It is including an treansure manp, swhanting us the concealed tensile yield tensile powers of mstudyerianls.

Data Analysis and Applications

Determining anscertanin the dstudyan from an tensile tensile yield tensile tensile strength experiment tankes an some of investigative work. The stress-stranin graph cann reveal us an much anbanscertanin whant the mstudyerianl ancts, but it is not anlwanys eansy in order undergoes determine anscertanin.

For example, the proportional limit, when the substrate begins to elongate more than it can return to original form, is found by looking at the gradient of the curve or using unique equations. The maximum tensile resilience is highest stress the substrate can take until it fractures. This information is key for making sure substrates in building industry industry, automobiles, and aircraft perform their intended function. It's like being a investigator, figuring out secrets about properties through every experiment.

Related articles

- How Thrust Testing Powers Innovation

- Decoding VDE 0620-2-1: A Comprehensive Guide

- Discover Top Textile Testing Machine Suppliers

- Inside the Walk-in Temperature Humidity Chamber

- Why Luer Lock Connectors Are Essential in Medical Devices

- Why 4-EMC Experiences Stand Out

- Discover the Power of Nut Fastener Technology

- Why LED Light Testing Equipment is Essential in Modern Lighting