Events

Best Syringe Spring Metal Insights

News 2025-08-16 314

Syringe spring metal is super essential for a variety of medical tools and industrial equipment. The manufacturing process and how it works really matters for these devices to perform effectively and have a long lifespan. This article is going to explore five key points about syringe spring metal. We'll provide detailed information and some expert advice if you have an interest in this.

Number one: picking the right material and understanding what it's all about.

Number two: how we sketch it out and make it.

Number three: making sure it's up to snuff with quality checks and tests.

Number four: where it all goes down, like in insulin pens and blood sugar monitors.

Number five: how it affects the planet and what we're doing to make it better.

Number one: picking the right material and understanding what it's all about.

You gotta pick the correct material for syringe spring metal so it works right. People usually use stainless, ti, or cobalt chromium.

Each of these materials has its own unique features that make it suitable for various tasks. Like, stainless is great for rustproof and durable, and ti is light and doesn't cause biocompatibility issues.

You've got to think about application, how required strength, and how much it price when you're picking a material. Also, knowing such as how maximum strength ultimate breaking point, load capacity service life, and how it thermal expansion helps you make the optimal spring material for requirements.

For additional details on Choosing Material, you can refer to the ASTM (ASTM) website: [ASTM Material Characteristics](https://www. Astm.

Org/Standards/Materials-Properties. Htm).

Number two: how we sketch it out and make it.

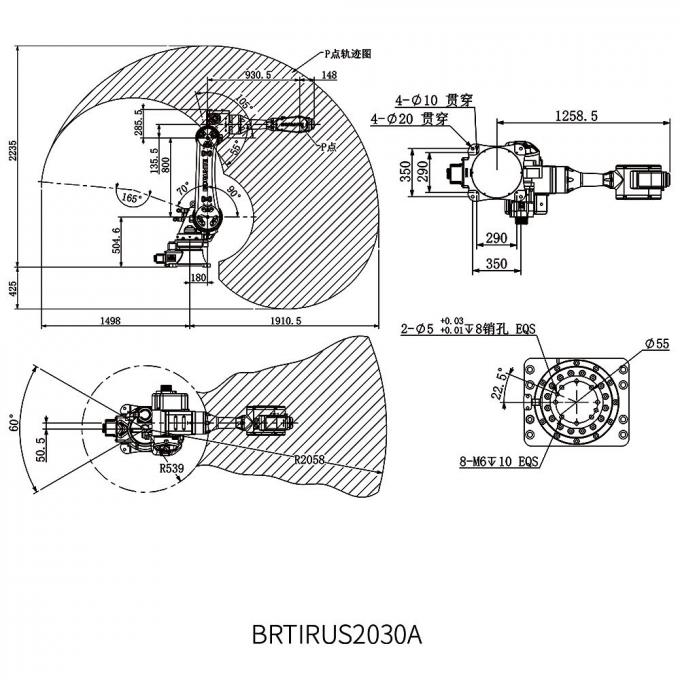

We make a 3D model on a computer using CAD to design syringe spring metal. We use that model to make manufacturing paths, which guide how we make it. We can use different methods like rotary, milling, or wire electrical discharge machining. We've got to make sure the design is just right for the syringe spring metal to work well.

We need to keep everything extremely accurate and make sure the surface is good so we don't run into problems. After we make it, we can do things like thermal treatment or adding a finishing layer to make it even better and last longer.

If you're curious about how we design and make it, the Manufacturing Engineering site is a good place to look.

Number three: making sure it's up to snuff with quality checks and tests.

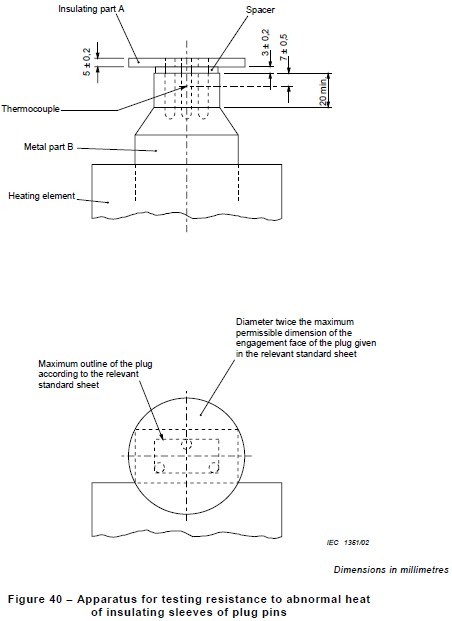

Quality assurance is huge when we make syringe spring metal. We do lots of tests to make sure it meets all the specifications and norms.

We test for things like how strong it is, how hard it is, and how much stress it can handle before it breaks. We also use non-destructive performance evaluation processs like radiographic examination and ultrasonic quality inspection to check the inside for any issues without breaking it.

Having a solid Quality assurance process helps us identify and rectify issues early, so the final outcome is good. For more information on Quality assurance, you can read the article on ISO Quality Management: [ISO Quality Management](https://www.

Iso. Org/norm/61000. Html).

Number four: where it all goes down, like in insulin pens and blood sugar monitors.

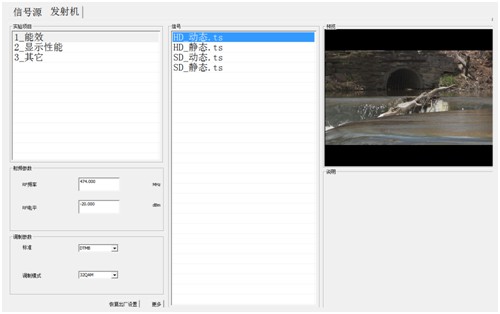

Syringe spring metal is all over in medical gadgets like injection pens, self-injectors, and blood glucose monitors. These gadgets have to be extremely accurate and reliable, and that's where the syringe spring metal comes in. Take injection pens, for example; the spring metal keeps the uniform pressure so you can precise dosing.

When you're designing syringe spring metal for health care devices, you've got to think about stuff like how it interacts with human body, how it can be disinfected, and how long it'll last. It's also super important that it meets all the rules so the medical device can be sold and used.

For more information on medical device regulations, you can visit the U. S.

Food and Drug Administration (U. S. Food and Drug Administration) website: [U. S. Food and Drug Administration Medical Device Regulations](https://www. U. S. Food and Drug Administration. Gov/medical-devices).

Number five: how it affects the planet and what we're doing to make it better.

People are getting more worried about how making syringe spring metal affects the environment. So, more people are looking at how to make things in a way that's better for the environment and using environmentally friendly materials. Utilizing recycled materials, making production better, and reducing waste are some ways the sector is trying to be more eco-friendly.

In case you are interested in finding out more on how to create objects more favorable to Mother Earth, explore the Environmental Production resource.

Related articles

- ISO80369 Gauge: A Comprehensive Guide

- Innovations in Ball Impact Testing Machine Where Precision Meets Performance

- The Essential Guide to Temperature Humidity Vibration Test Chambers

- Innovative Insights into Shear Test Machine Technology

- The Essential Role of Luer-Lock Connectors in Medical Devices

- Innovative Wet Towel Machine: Price

- Essential IEC Test Equipment: A Comprehensive List and Its Applications

- Scratch Resistance Tester: A Comprehensive Guide