Events

Advancing Burst Test Equipment Technologies

News 2025-08-09 286

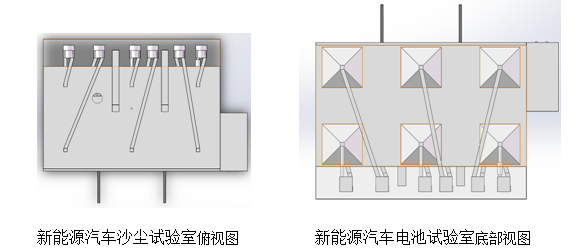

So, when we're talking about evaluating how tough and hard substances are, burst test equipment is vital for the purpose of the purpose of ensuring securety and dependability. It's employed in applications like manufacturing facilities, medical institutions, and even launch vehicles. Knowing the details of these testing devices is highly important. Let us explore some of the key key issues related to this critical device.

What is the significance of burst test equipment in material testing?

How does burst test equipment work?

What are the different types of burst test equipment available?

How can one ensure accurate and reliable results from burst test equipment?

What are the future trends in burst test equipment technology?

What is the significance of burst test equipment in material testing?

Burst test equipment is super crucial for finding out how much tensile strength of a material can handle before it ruptures. It's key for designers and manufacturers to make sure their stuff is safe and going to last a long time. American Society for Testing and Materials did a study and found out that using burst testing helps to spot any vulnerabilities in materials. It can stop stuff from ruptureing and keeping incidents away in critical components.

How does burst test equipment work?

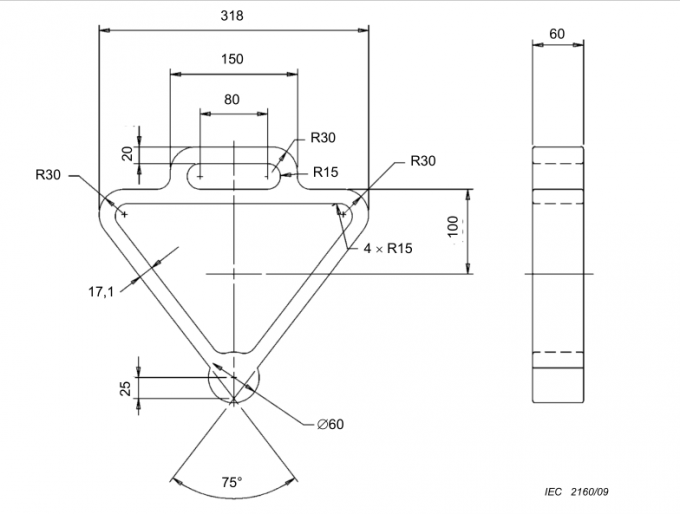

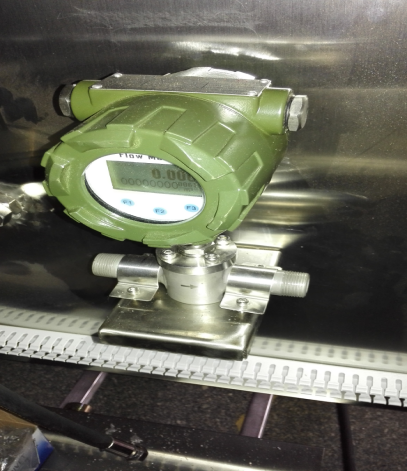

Burst test gear usually has a big compressor, a container for holding pressure, and a system for controlling everything. You put the material in there, and the compressor slowly builds up the pressure.

As pressure increases, the material starts to become extremely stressed until it bursts. They then measure the pressure required to cause the material to rupture as well as use this information to determine the material's strength as well as durability.

What are the different types of burst test equipment available?

There's a variety of distinct rupture test configurations out there, all for different materials as well as uses. You got your hydraulic, pneumatic-driven, as well as electro-pneumatic-driven testers. They're all unique as well as suited for different purposes.

Each type has its own advantages. Hydraulic-type apparatus are mostly used for polymers as well as elastomers, while the pneumatic-driven-type apparatus are more suitable for metals as well as composite materials.

How can one ensure accurate and reliable results from burst test equipment?

To get good, trusty results from these devices, you gotta be precise in setup and calibration. Plus, you've got to keep up with the ongoing maintenance to make sure they stay accurate.

And don't forget, using standard test procedures and stuff like the ASTM standards can help keep your results the same every time. From my end, hanging with pros and keeping an eye on new industry rules really made a difference in our testing accuracy.

What are the future trends in burst test equipment technology?

The future for burst test tech looks like it'll be all about increasing its intelligence, enhanced accuracy, and faster. With more fancy materials and emerging products, these testers are going to be super important for making sure quality-assurance stay on point. We can expect to see things like intelligent sensors, speedy data analysis, and cool command systems become the norm in modern burst test gear.

Related articles

- Revolutionizing Testing: Top 5 Demands for Mechanical Shock Testers

- Insights into Battery Pack Testing Machine Companies

- Darbe 1000: The Ultimate Guide

- Unveiling UVA ISO: Insights into Its Impact

- Optimizing Load Transfer in Tensile Structures

- Upgrade Your Melt Flow Indexer Knowledge

- Innovations in Adjustable Knee Joints: Enhancing Mobility for Who Needs Them

- Mastering OT Instruments: A Musical Odyssey