Events

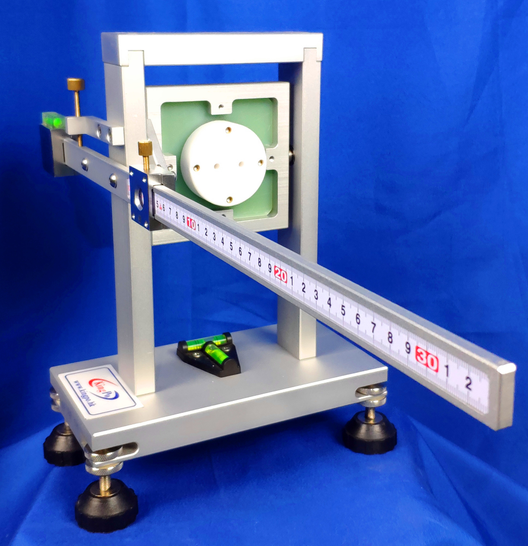

Sponge Pressing Coefficient Tester Factories: Plans for Excellence

News 2025-08-09 235

Look, the demand for top-notch sponge pressing coefficient tester factories is skyrocketing. We gotta figure out what customers truly seek. These factories don't just make good testers; they're like the backbones of the sponge industry, maintaining strict quality control.

4. Environmental Sustainability

1. Customized Solutions

Customers today are all about getting something that fits their specific needs when it comes to testing. More and more, sponge pressing coefficient tester factories are zeroing in on making solutions that function effectively for different fields, like cars, constructions, and even medical field. These solutions usually mean throwing in some advanced technology to make sure the testing is exactly accurate and consistent.

2. Quality Assurance

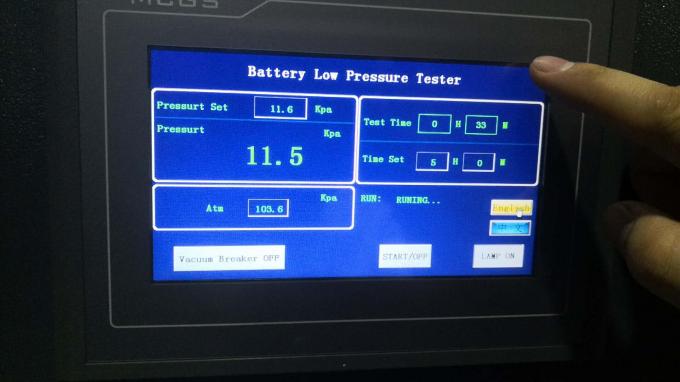

Quality has to be the highest priority in the sponge pressing coefficient testing game. Factories have to follow very strict regulations to make sure all testers hits the maximum standard. It's all about doing comprehensive testing, adjustments, and getting certificates to keep customers satisfied and trusting us.

3. Technological Innovation

Technology has transformed the industry for sponge pressing coefficient testing. Factories are now jumping on the artificial intelligence and machine learning bandwagon to make their testers more accurate and efficient. These innovations are not only cutting down the testing time but also boosting the product quality being tested.

4. Environmental Sustainability

<pAs the world becomes more focused on being eco-friendly, sponge pressing coefficient tester factories need to start doing more environmentally friendly practices. It's about using ecological materials, using reduced energy consumption, and reducing waste. By environmental sustainability, these factories can help the planet and also attract environmentally conscious customers.

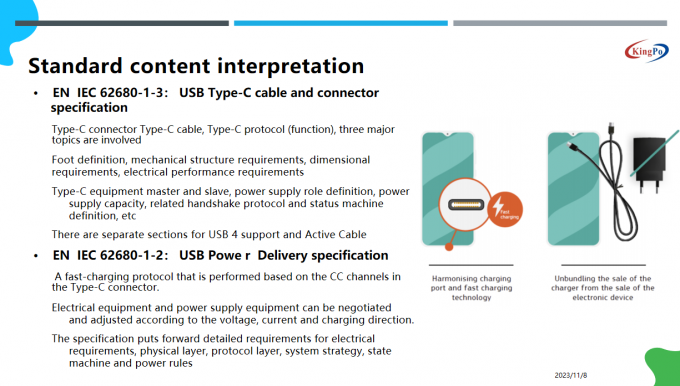

5. Global Reach

As the sponge industry gets bigger globally, manufacturing plants need to be prepared to interact with global clients. That means knowing all the various regulations globally, adapting to with various cultural nuances, and making sure we've got excellent customer service after the sale. Manufacturing plants that deal with these obstacles will become like the top performers in the international market.

Related articles

- Medical Ultrasound Detection: Enhancing Diagnostics in Healthcare

- Scratch Resistance Tester: Unveiling the Key to Durable Coatings

- Finding Local Truck Testing Equipment Calibration Services

- When Evaluating Electric Vehicle Motor Performance Testing

- What's New in Yarn Testing Machines?

- Ensuring Precision: The Role of Biological Safety Cabinet Calibration Devices

- Box-type Resistance Furnace: The Ultimate Muffle Furnace Guide

- What is ISO 20653 and Its Key Requirements?