Events

Tailoring Springs: A Deep Dive

News 2025-08-07 296

In precision engineering, creating specialized springs is a big deal. It's a principal service used by lots of different industries. These springs are like the quiet silent stars in devices and machinery. They give the support, stretch, and toughness needed for excellent performance. As people want more unique items, let's dive into some major inquiries about creating specialized springs.

What are the usual materials they use for making those special springs?

How do you determine the right spring design for a particular application?

What are the challenges of producing custom springs?

How can custom spring manufacturing benefit your business?

What is the future of custom spring manufacturing?

What are the usual materials they use for making those special springs?

Custom spring production relies on a variety of materials, each selected based on their specific characteristics. Carbon steel, high-toughness stainless steel, and beryllium copper are big hits due to their strength, durability, and resistance to corrosion. Choosing the appropriate material is extremely important. It influences the longevity of the spring, the weight capacity of the spring, and if it suits your intended use.

How do you determine the right spring design for a particular application?

Selecting an appropriate spring design is all about Examining its requirements carefully. You've got to think about stuff like The weight it will support, Its bending characteristics, and Its operating environment. Engineers usually use Computer software or technology and Prototype versions to Ensure the spring is suitable for the job.

What are the challenges of producing custom springs?

Creating custom springs is Not a simple job. It's got Its numerous challenges. These parts need to be Extremely accurate. The way they're made has to be able to Accommodate a variety of shapes and dimensions. And, making sure they're Uniform in quality and will Ensure longevity, Irrespective of the number of production batches, is a must.

How can custom spring manufacturing benefit your business?

Putting funds into making bespoke coils can really pay off for businesses. You can create these coils just exact for what they need to do, which can create your goods function better and be additional trusted. Plus, they might save you funds because you might not need so many components, or you might not have to alter your designs much.

What is the future of custom spring manufacturing?

The prospects of making these special coils will probably be influenced by new technology and better ingredients. We expect that automation things and using AI will create the procedure quicker, and new ingredients will create the coils even better. This means designers will be able to create additional innovative and productive coils for even additional applications.

Related articles

- Why Keep an Electrical Test Equipment List

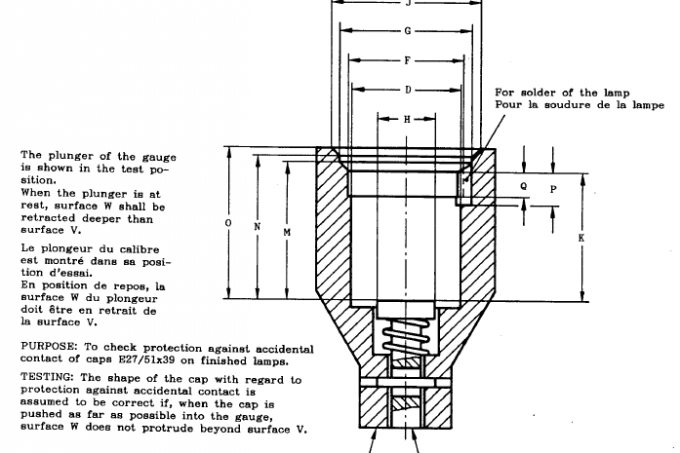

- E27 Lamp Gauge: A Comprehensive Guide

- Coupon Code for Crush Tester Manufacturer

- The Essential Guide to Prefilled Syringes

- The Essential Role of Luer-Lock Connectors in Medical Devices

- Who's Navigating the Battery Shock Test: A Comprehensive Guide

- HDT Revolution: Unveiling the Power of Hyperdrive Technology

- Decoding Foam Press Tester Coefficients