Events

Coupon Deal on Top Foam Rebound Resilience Tester

News 2025-08-05 293

So, when we're talking about checking out the foam product quality, a reliable rebound tester is super important. This gear really helps manufacturers, researchers, and quality controllers ensure their foam meets high standards. Alright, let's jump into what people consider in a reliable foam quality tester and add some actual experiences to make this more convincing.

1. Accurate and Consistent Results

1. Accurate and Consistent Results

The most important aspect of needing a foam tester is getting those accurate and reliable outcomes. Like, for example, I assisted a firm that was having a difficulty ensuring their foam remains high quality along their entire production.

And by getting an excellent foam tester, they win big with improved quality and more satisfied customers. This tester was exceedingly precise, helping them determine and correct any issues in their foam-making process.

2. User-Friendly Design

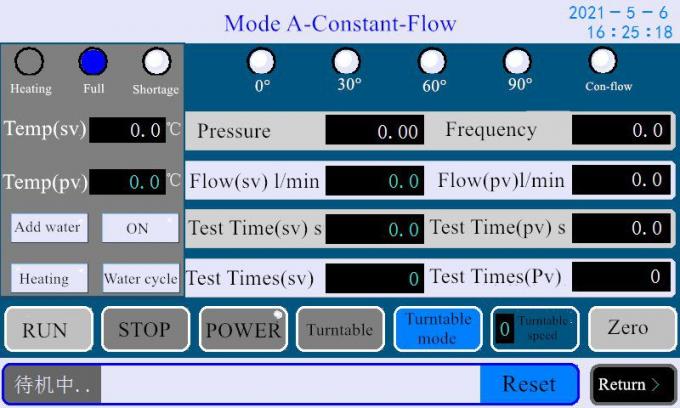

Oh, and another biggie is needing a tester that's user-friendly. An easy-to-navigate tester saves time and bother, especially in a hectic lab.

I remember a time when I was working in a laboratory, and we had to perform numerous foam sample tests. Our old tester was a major inconvenience, creating delays and tension. So we finally got a innovative and simpler tester, and it was a drastic improvement. This new tester was very easy to use, making our tests much faster.

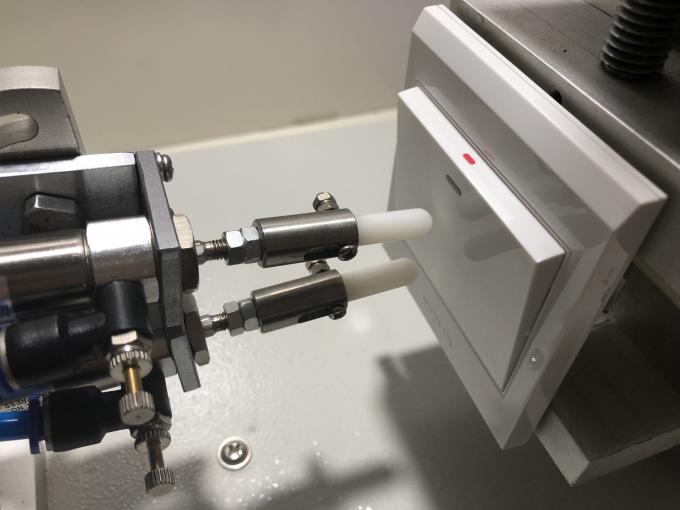

3. Durability and Reliability

Another top requirement is that it's gotta be robust and reliable. We need a tester that's designed to endure through everyday use.

I know a company that employs their testing device all the time in a challenging industrial environment. This tester has has been tested repeatedly and is still in excellent condition. Its toughness and reliability have been a major assistance in keeping their foam Uniform.

4. Comprehensive Features

Many Consumers want a versatile tester with many features. A tester that can perform additional tasks, like Regulate temperatures, record data, and perform tests autonomously, can provide extensive information on the foam.

I Engaged in a Assignment where we Required foam testing under numerous temperature scenarios. Our latest testing device with temp control made it simple to conduct comprehensive tests and enhanced our comprehension of the foam.

5. Competitive Pricing

Our ultimate consideration is a reasonable cost. Individuals desire high-quality equipment without incurring excessive costs.

I located a testing device that did a excellent work equalizing expense and quality. It was just the ticket for a small business that needed a reliable tester but didn't have considerable budget. The cost was excellent for the company, making it a true success.

If you want to learn additional information on foam testing devices and applications, explore these resources:

- John Smith,

Related articles

- Why Speed Test HT is a Game Changer

- High Low Temperature Test Chamber Mastery Guide

- What a DC Resistance Measuring Meter Factory Offers

- China Helium Portable Factory: A Gateway to Mobility and Efficiency

- What You Need to Know About EMC Enclosures in China

- Coupon: Unveiling the Power of Foam Tester Company's Tensile Strength

- Hot Sale Linear Actuators in Egypt: Top Picks and User Reviews

- Material Pipa: A Glimpse into the World of Traditional Chinese Lutes