Events

Optimizing Nuts Filling Machine Manufacturer Tracking

News 2025-07-07 341

Hey there, producers! Are you wanting to make your nuts filling machinery run smoother with some clever tracking? So, you've stumbled upon the correct place! In this here piece, we're diving into how to monitor those nuts-filling machines with a tracker. We'll check out five super duper topics that could really up your game.

1. Advanced Technology Integration

1. Advanced Technology Integration

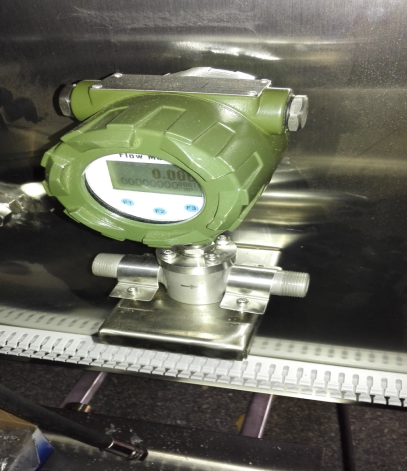

The really cool part about nut filler tracker stuff now is that they're using all sorts of fancy tech to ensure operations continue. We just got our hands on this super slick tracker that hooks into our machines with the help of those IoT gizmos and keeps a constant watch over the action. It lets us detect issues before they bring the whole thing to a halt, keeping the assembly line zipping right along and keeping productivity where it should be.

I've learned that staying abreast of the newest technological trends is a significant game-changer for us. Utilizing this innovative technology not only improved our tracking but we're also leading in the market competition with it now.

2. Enhanced Data Analysis

Data? That's the main focus in manufacturing industry, and our nut-filling machine monitoring system? It's no different. We've set up a sophisticated data analysis tool that's like possessing a foresight for identifying trends, forecasting what requires repair, and planning production wisely. It's helped reduce waste, prevented downtime, and just overall increased our share of the profit.

Identifying the appropriate tool for the huge amount of data we've got wasn't easy. After a lotta digging and trial and error, we finally picked out a solution perfectly suited to us. This thing has transformed our business for the better, and I'm pretty excited about how far we've reached.

3. Customizable Reporting

All manufacturers have their own way they wanna monitor their machine. That's why we went and created a reporting tool that our customers can customize what they really need. Whatever they're after — whether they want to closely monitor the assembly line, determine where things are problems, or plan their maintenance plans — we got that.

The only issue was making sure this reporting thing was pretty simple for users to use. We consulted with our customers, made a minor adjustments to the setup, and got the thing more intuitive, making it easy to determine how to navigate.

4. Training and Support

No matter how advanced a tracking system is, it won't really operate effectively if the users managing it haven't had adequate training. Which is why we offer excellent training and a considerable amount of support to make sure our customers are able to fully use our nut-filled monitoring tool to its maximum capacity. We've got a ton of tutorials and sessions from the fundamentals to the latest capabilities.

I've learned that crystal-clear communication is a big deal when you're providing training and support. Breaking down the complex matters into simplified concepts and giving folks some practical sessions? That's how we've helped our customers feel more at ease and able to operate our system without a problem.

5. Continuous Improvement

The manufacturing industry's always changing its spots, and I reckon continuous improvement is the key ingredient to stay on top. That's why we're committed to regularly updating our nuts filling machine manual manufacturer tracking system, incorporating upgrades and improvements based on our customers' feedback and market trends.

It's been tough trying to remain innovative and still satisfy our customers' actual needs these days. Listening to what our customers' activities and understanding their current and future needs helped us to make sure our system fits both their current strategy and future strategies, too.

Related articles

- The Essential Role of Environmental Simulation Testing Equipment

- Finishing Nuts and Bolts: Essential Tips and Techniques

- Essential Insights into Basic Surgical Tools

- Why the Leather Water Test Matters in Quality Assurance

- The Comprehensive Guide to High-frequency Electrosurgical Test

- How to Find Top Test Equipment Distributors in the USA

- Revolutionizing Medicine: The Advancements of Surgical Apparatuses

- Crushing Simulator Wiki: A Deep Dive