Events

Call for Enhanced Performance: Mastering Thermal Shock Testing

News 2025-07-03 384

So, you know, the thermal shock tester is pretty much a must-have in material and engineering sciences. It's made to mimic those super sudden temperature changes materials go through in the real world. It's all about ensuring the material durability and works well. Five key terms in this : temperature controlled environment, thermal cycling, material fatigue, fracture mechanics, and non-destructive testing.

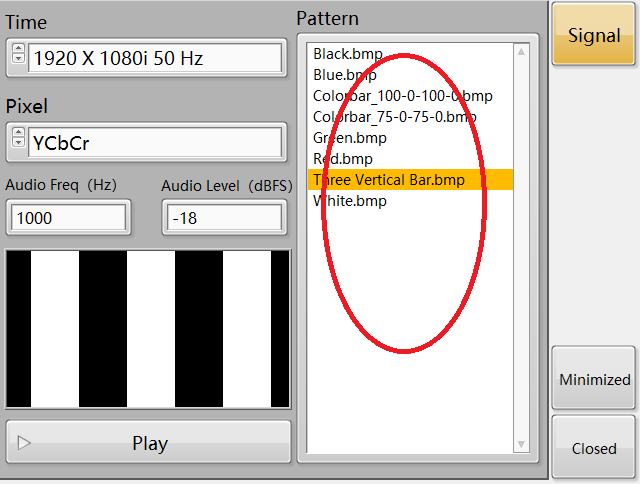

Environmental Chamber

Temperature controlled environments are crucial for conducting thermal shock tests, you know? They give you an environment where one can totally regulate the temperature, rapidly fluctuate the temperature, and do it right accurately.

Remember when I was working on this cool project to make a kind of of material? We used this chamber to mimic the temperature fluctuations this material would go through while flying. It let us test how the stuff would manage challenging conditions and refine it before we started making it a regular thing.

Thermal Cycling

So, thermal cycling is just putting a material through high and low temperatures over and over. It's all about seeing how strength of the material and what may ultimately fail.

Like, I was on this group which tested a new battery material to see how long it would last. We ran the material through a series of thermal cycles to ascertain its reliability and if it could last.

Material Fatigue

Material fatigue is when stuff starts to break down over time from being used over and over in the same way. It's super important in thermal shock testing, especially since materials can endure significant stress when the temp goes up and down fast.

I've personally done tests on some strong steel used for building stuff. We put the steel through all these extreme temperature changes with the tester to see how it behaves and then made it better for durable constructions.

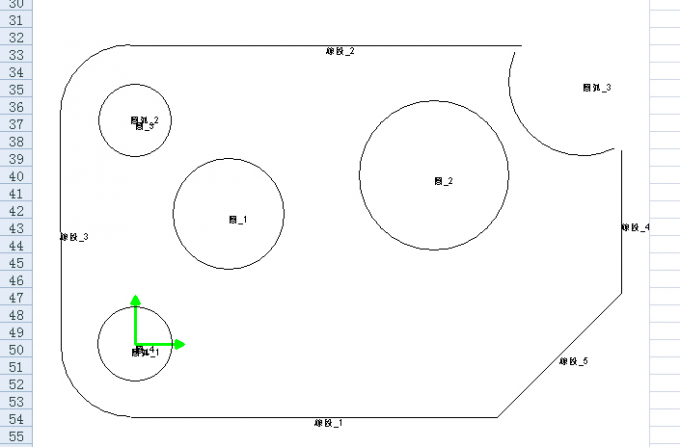

Fracture Mechanics

Fracture mechanics is all about understanding how cracks propagate within materials. It's key in thermal shock testing because it helps us figure out when something might break from cracks and prevent it from occurring.

I got to work on a project that was about using fracture mechanics in those thermal shock tests. We looked at where stress distribution and how cracks move to spot where things might go wrong and develop the material so it can handle severe temperatures.

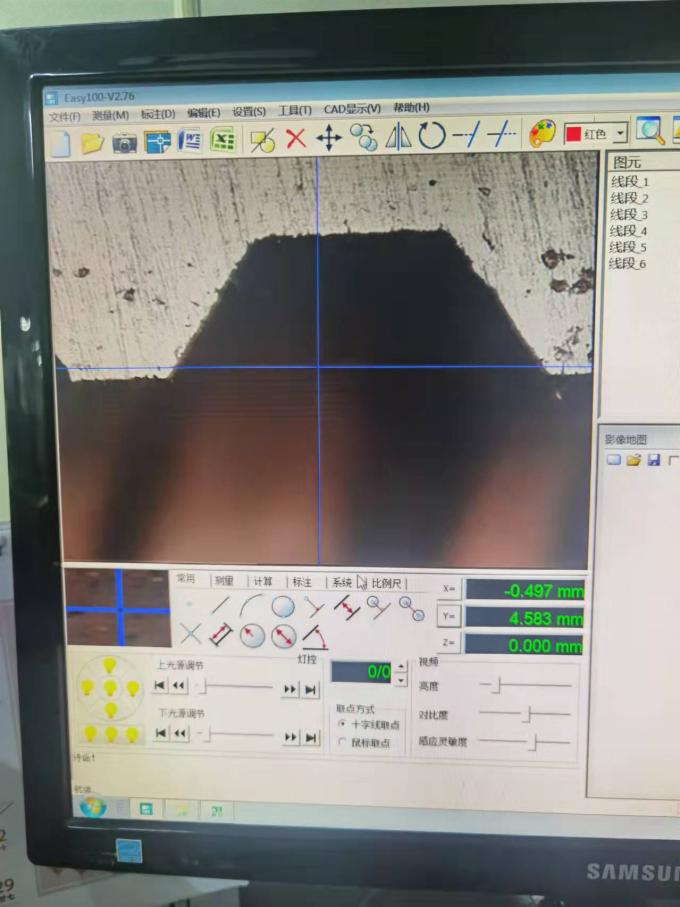

Non-Destructive Testing

NDT is when you inspect items without breaking it. It's really useful in thermal shock tests because you can evaluate the integrity of the material without having to damage it.

I was in a project where we required to use NDT for inspection the intactness of this new composite material employed in aerospace. We made sure the the material was trustworthy and secure, and we didn't mess it up doing it.

For more information and resources on thermal shock testing, I recommend visiting the ASTM International website (www. Astm.

Org) and the National Institute of Standards and Technology (NIST) website (www. Nist. Gov). These organizations offer a broad range of information about material examination and criteria.

Related articles

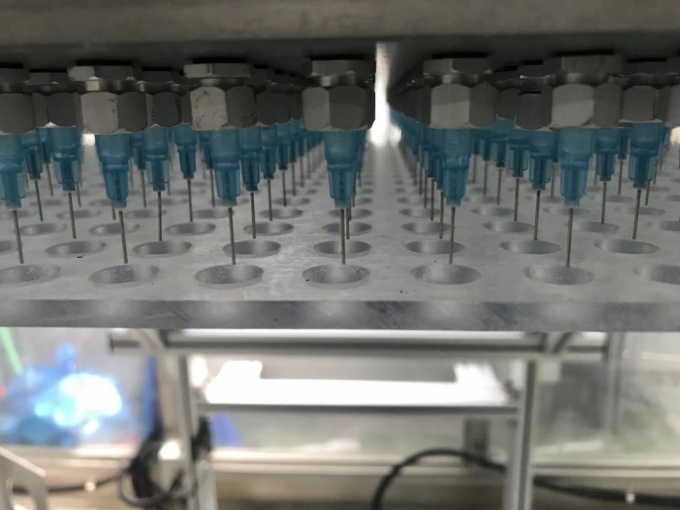

- Unlocking the Power of Electronic Universal Testing Machines

- Innovative Luer Lock Connector Syringe Needle: A Comprehensive Review

- Unveiling the Testing Equipment Landscape in China

- Coupon Code for Ceramic Rockwell Hardness Mastery

- The Necessities of Industrial Test Equipment Co.

- What You Need to Know About Strength Ratio Bolt

- The Essential Guide to Tooth Picks

- Who Needs IPX2 Waterproof Rating?