Events

Mastering Salt Spray Corrosion Test Chamber Efficiency

News 2025-06-30 322

You see, that piece of salt spray test chamber equipment is extremely important for guaranteeing the longevity of the goods. It simulates the severe environmental conditions that can lead to corrosion, allowing producers to evaluate and enhance the corrosion avoidance of their goods.

1. Optimizing Salt Spray Corrosion Test Conditions

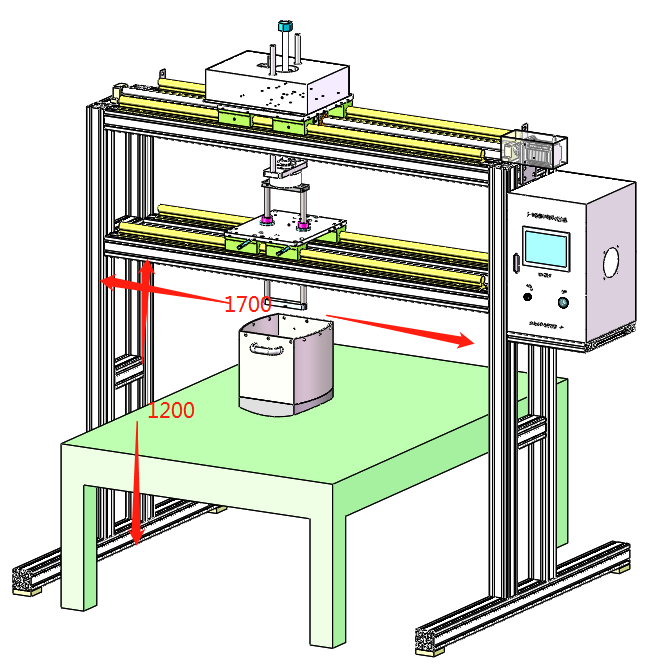

2. Selecting the Right Salt Spray Corrosion Test Chamber Model

3. Ensuring Proper Calibration and Maintenance

4. Integrating Salt Spray Corrosion Testing into Quality Control Processes

5. Training and Certification for Operators

1. Optimizing Salt Spray Corrosion Test Conditions

To get positive outcomes from that salt spray test thing, you have to adjust the parameters correct. You've got to set the ambient temperature, the relative humidity, and that salt spray solution just correct. For instance, for instance, National Institute of Standards and Technology did a study and said if you maintain it at from 35 to 50 degrees Celsius and 95 to 100% relative humidity, it has a significant effect.

2. Selecting the Right Salt Spray Corrosion Test Chamber Model

There exist a variety of salt spray chambers out there, each featuring its own unique attributes. You have to pick the correct one that suits your testing requirements. I observed a Amazon review that pointed out how crucial it is important to to possess a chamber with variable spray directions for adequate coverage.

3. Ensuring Proper Calibration and Maintenance

You gotta keep that thing calibrated and maintained so its reliability is assured. This entails verifying the temperature and moisture sensors, cleansing the nozzles, and replacing outdated components. The ASTM mandates proper upkeep in order to prevent erroneous outcomes.

4. Integrating Salt Spray Corrosion Testing into Quality Control Processes

Putting corrosion testing by salt spray in your inspection process facilitates identifying issues early, thereby avoiding the need for repairs or recalls later. Like, one major automaker showed how it used corrosion testing by salt spray to identify and correct issues in the initial phases of vehicle manufacturing.

5. Training and Certification for Operators

<p You need to educate and license the people who utilize the salt spray cabinet so they can use it securely and proficiently. They need to know how to do the exam, maintain precise documentation, and be conscious of the dangers. The ACC carried out a study and discerned that operators which are accredited usually get more consistent and outcomes.

Related articles

- Nurturing Precision: The Essentials for Surgical Instruments Who

- Sealing Tester Mastery: Top 5 Hot Topics Unveiled

- Conducting the Horizontal Bunsen Burner Test for Cabin Safety

- Lure Lock Connectors: Mastering Secure Connections with Coupons

- Innovative Solutions: The Role of Acceleration Shock Testers in Modern Engineering

- Why Speed Test HT is a Game Changer

- Edge Tester: The Ultimate Guide to Cutting-Edge Testing

- Innovative Solutions by High Speed Impact Tester Manufacturers