Events

Decoding the Dynamics: Exploring Bolt and Nut Properties

News 2025-06-17 418

Understanding understanding how Bolts and nuts fasteners function is very important in engineering and construction. These small components are extremely important for holding everything together and functioning properly. You need to consider such as the strength and durability of the materials, and the required tightness—there are many factors to consider!

Friction and Torque Tension Relationship

Material Properties

Bolts and nuts fasteners are available in various materials, and each has its unique strengths. Stainless steel alloy is ideal for moist environments, such as on boats, as it is resistant to rust.

Carbon-based steel is extraordinarily strong and usually used for robust materials. I had a project where the bolts were deteriorating because they were in salty water. So I looked it up and found out that rust-resistant bolts would be way better for that kind of situation, since they have a longer lifespan.

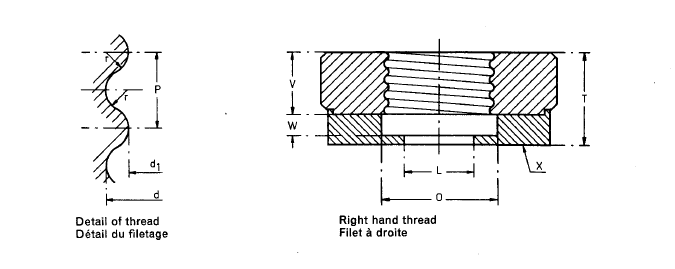

Threaded Design

The way bolts and nuts are threaded is super important too. The thread spacing, form, and standard all make a difference.

For instance, a tighter thread means more threads per inch, which makes the bolt secure things more tightly. I had trouble with a bolt on a recent repair work because it had a wide thread spacing, didn't secure the connection. Switching it out for a bolt with a finer pitch solved the problem, got that bolt securely tight, and prevented it from loosening later.

Hardening and Tempering

Fasteners require heat treated to enhance their strength and increase their durability. Heat treatment hardens them and less prone to wear, and also makes them tougher and increases their flexibility.

This process ensures the bolt can withstand pressure and not break. On one occasion when a bolt failed under pressure, and upon inspection, it was found it was not heat treated properly. Upon realizing how crucial heat treatment was, I corrected the issue and ensured the project was secure.

Friction and Torque Tension Relationship

Determining what torque is needed to tighten Fasteners is crucially important. It revolves around the amount of twist results in the bolt being sufficiently tight.

This ensures the bolt is securely tight to maintain the integrity of the assembly. I employed a torque wrench for a recent installation to achieve the optimal tension. By adhering to the manufacturer's guidelines assured that the assembly was secure and safe.

Related articles

- What Makes Belt Straps Essential?

- How to Find Test Equipment in Lake Mary, FL

- Why IPX Waterproof Rating Matters

- Mastering the Flexometer: Who Can Use It?

- Master the Art of Folding

- Advancing Burst Test Equipment Technologies

- Plans for Seamless Connections: Luer Lock to Luer Slip Connector Mastery

- How to Choose the Right Sponge Tensile Strength Tester Company