Events

Battery Pack Testing Where Quality Meets Efficiency

News 2025-06-14 316

You know, examining battery packs is extremely important to ensure our battery-operated devices works secure and safe. Being a leader in this field, I've seen these testing systems develop over the years.

1. High-Speed Testing Capabilities

These machines are a important matter because they ensure batteries meet the criteria on quality, no matter what they're being used for, from mobile devices to electric vehicles. In this piece, I will explore the primary requirements for these battery testing systems. I'll provide key insights into the issues we've encountered and the knowledge we've gained over time.

1. High-Speed Testing Capabilities

One big request in battery testing is extraordinarily quick testing. We're talking speed here, folks! With technology advancing rapidly, we need faster and more efficient tests than ever before.

Our group developed a testing device that can do more than one hundred evaluations per minute, really accelerating processes for large quantities of batteries. This is not only quicker but also lets us do more tests, which really helps with product quality management.

2. Advanced Data Analysis

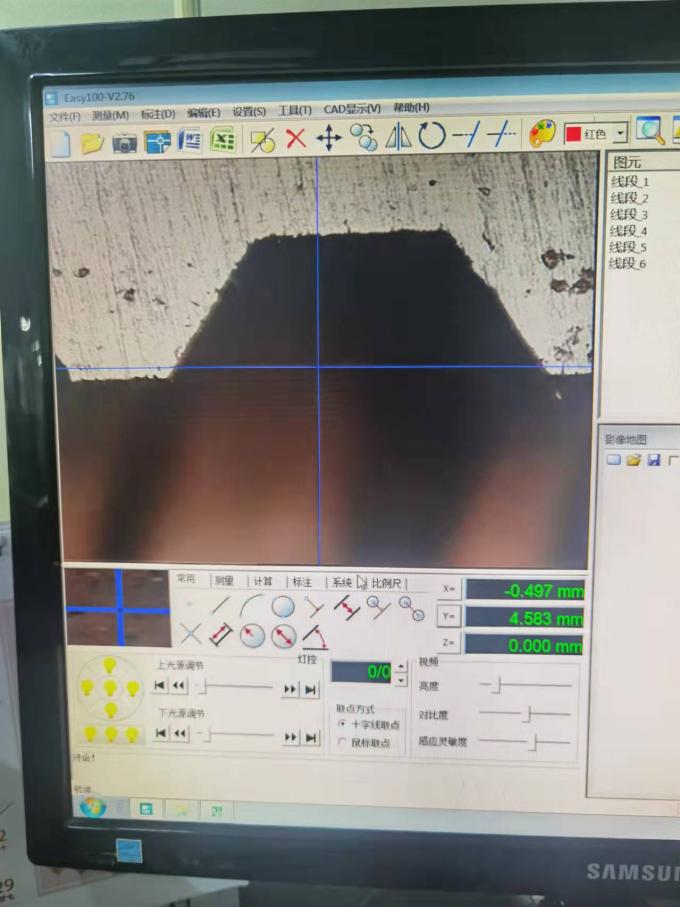

Obtaining precise information on battery effectiveness is crucial to detecting issues in advance. Our machine has this super exceptional software that handles vast amounts of data super fast. This means we identify aspects that may be overlooked, producing superior batteries and ensuring our safety.

3. Scalability

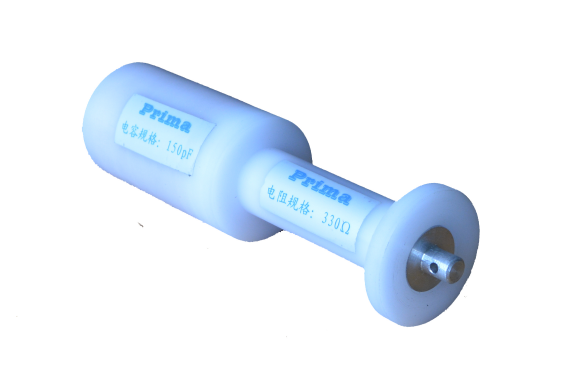

Cells are evolving constantly, so we need our testing equipment to be capable of accommodating any battery type. We designed our battery pack testing machine to be easily adaptable to a range of battery types and combinations, ensuring that it remains relevant as . That agility keeps us ahead of the curve and lets us fulfill a variety of customer requirements.

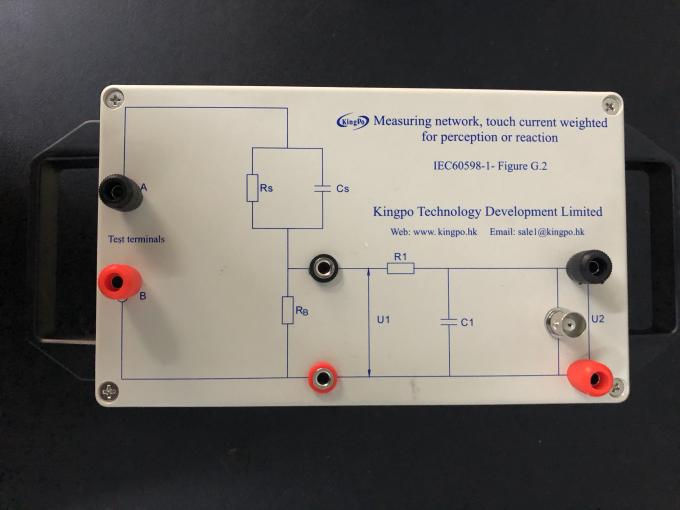

4. User-Friendly Interface

We need an control panel that's intuitive, so anyone can run the tests without needing considerable training. Our testing equipment has a friendly, graphic control panel, so configuring and executing tests is easy. This has made it super easy for us and improved significantly improved productivity.

![]()

5. Environmental Testing

It's important to test Cells under different climatic and dynamic conditions to make sure they work well out in the field conditions. Our testing equipment has this cool room where we can simulate a diverse range of weather conditions and kinematic environments. This means we can check the Cells out really good and make sure they'll work anywhere.

Related articles

- Maximizing Ceramic Strength: A Comprehensive Guide

- Mastering the Tensile Strength Test Machine

- China's Chemical Experiment Machines: A Comprehensive Overview

- What is a Luer Lock Connector? A Comprehensive Guide

- Secure Flat Abrasion Tester Quotes

- When Seeking the Best High Quality Foam Rebound Test Equipment

- Unveiling the Testing Equipment Landscape in China

- Where PIM Cap 4 Meets Modern Needs