Events

Level Gauge Devices: Essential Insights

News 2025-06-05 331

Level measurement devices, you know, they're pretty much a essential across various sectors, from manufacturing to agriculture. They're made to tell us how much material or substance is in vessels, storage tanks, or conduits, keeping everything operating productively. With all these technological advancements, people are starting to wonder about how well these devices function, how trustworthy they are, and how productive they can be.

So, what are the different kinds of level gauge devices out there?

How accurate can these level gauge devices be, right?

So, what's the deal with using level gauge devices in industrial processes?

What's the future looking like for level gauge technology?

So, what are the different kinds of level gauge devices out there?

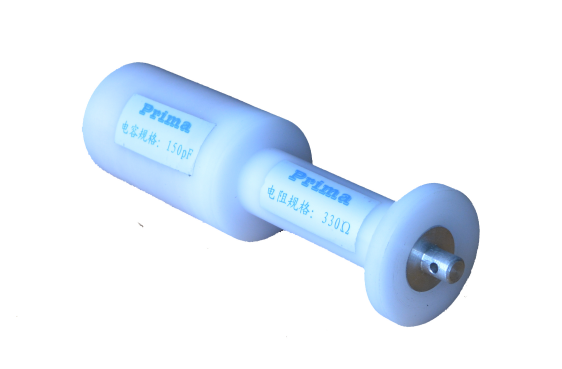

Measurement equipment for Elevation come in various types, each suited for different environments and applications. The usual suspects are Bubble or floating Elevation indicators, Bourdon gauges, those ultrasonic and Radio wave measurement gauges.

Bubble or floating Elevation indicators operate using a floating sensor to quantify the depth or height. Bourdon gauges, on the other hand, utilize the exerted force from the substance of the contents being measured to figure it out. Ultrasonic and Radio wave measurement gauges? They operate using auditory frequencies and microwaves or radio frequency signals perform their function, respectively. Determining or understanding the differences differences amongst them is key to getting the appropriate apparatus for your specific application requirement.

How accurate can these level gauge devices be, right?

The accuracy can really vary, depending on what kind and how good the device is. Top-notch level gauges, like the ones using radar or ultrasonic tech, can be highly precise, to a few millimeters even.

However, factors such as temperature and pressure, and what you're measuring can throw off the accuracy. You must select a device that provides sufficient accuracy for your application and maintain its calibration for optimal performance.

So, what's the deal with using level gauge devices in industrial processes?

They're good for industrial processes since they contribute to safer and more efficient, and help you save some money. They give you live readings, which prevents overfilling or underfilling issues and can avert harm to your equipment or losing your material.

They also allow workers adjust the procedure to reduce energy consumption and improve product excellence. Furthermore, they can be connected to automated systems, too, which makes the whole procedure even seamlesser and more effective.

How do you keep these level gauge devices in tip-top shape and make sure they're calibrated properly?

Keeping them maintained and calibrated is a important aspect for Ensuring they're accurate and last long. Frequent cleaning, inspection, and upkeep can prevent issues like blockage, corrosion, or getting malfunctioning.

It is recommended that perform calibration on them in accordance with the manufacturer's guidelines and at the appropriate intervals. At times, you may require unique instruments or equipment to perform calibration on them. Ensuring your devices are kept in proper condition and correctly calibrated can help you save considerable time, money, and materials over the long term.

What's the future looking like for level gauge technology?

The future will feature increased wireless communication, greater IoT integration, and smaller and more energy-efficient devices for level measurement devices. These trends should mean superior, more user-friendly, and more cost-effective level gauge devices, which will make them even more valuable in various industries.

Related articles

- Revolutionize Your ECT Sample Cutting with Experts

- Coupon for Secure Screw-on Plastic Plates

- Buy Concora Medium Fluter Tester - Essential Needs and Real-Life Experiences

- Rolling into the Future: 2 Roll Mill Insights

- Mastering the IP Test Chamber: Key Demands and Solutions

- Decoding Nulge: A Journey into the Unknown

- The Essential Aspects of Vehicle Rolling Test Devices

- Buy