Events

Upgrade Your Testing with Torsion Speed Mastery

News 2025-06-05 353

Been working in the mechanical engineering field for a while, evaluating materials and seeing how the equipment has progressed. I'm talking about this adjustable torsion speed testing machine—it's a major innovation in our field. I'm gonna chat about five key things about it today, drawing on personal experience and everything I've learned over the years.

1. Enhanced Precision in Material Testing

3. Integration with Data Analytics

4. Industry Compliance and Safety Standards

5. Sustainable Testing Practices

1. Enhanced Precision in Material Testing

This device allows us to perform extremely accurate tests on substances. My expertise in material science showed me that this level of precision is crucial for reaching accurate outcomes. We can adjust the velocity and angle, which provides us a more detailed analysis at how the material behaves. All of this contributes to reliable information for engineering decisions.

I have observed a significant change in the regularity of experiments using This device. It assists us forecast how materials will react under pressure way better, which is vital in sectors such as aerospace and automotive manufacturing.

2. User-Friendly Interface

The device's interface is extremely easy to use. Even individuals who are not tech-savvy can operate it. The layout is highly intuitive that it's almost self-explanatory, which makes executing reliable tests effortless.

It's not solely for professionals—and it is highly accessible as well for learners and investigators. The goal is igniting innovation and bringing together individuals from various disciplines to collaborate.

3. Integration with Data Analytics

Being able to connect this machine to data analytics software is super cool. It lets us analyze and process data in immediate. With my background in data science, I get how big of a difference this makes for fast insights and making informed decisions.

This has totally streamlined my workflow. I can handle large data sets no problem and distribute findings with my group super fast. It shows how tech is fostering the connection between engineering and data-informed decisions.

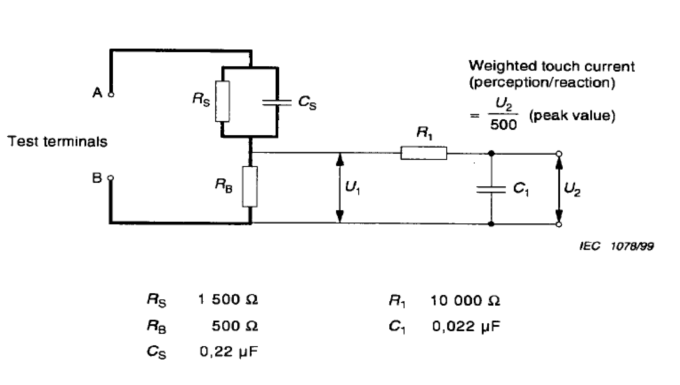

4. Industry Compliance and Safety Standards

We can't mess around when it comes to safety and product quality during testing. I feel comfortable using this machine, since it hits the most stringent industry standards. The design is robust, and it goes through a lot of quality inspections before it's on the market.

With this adherence, engineers and scholars can rely on the information this machine produces, giving them a strong base for their work.

5. Sustainable Testing Practices

I'm all about being environmentally conscious, and this machine excels at that. It's power-saving and reduces waste output. It's a great example of how technology can assist us preserve our environment without compromising on performance.

This this machine is not merely a tool—it's a disruptor for innovation, precision, and sustainability in material testing. I'd totally recommend checking it out if you're interested in advancing your research and engineering to the new frontier.

Related articles

- Price-Effective Short Circuit High Power Testing Solutions

- What is a MEDTEQ Tester and Its Essential Demands?

- Masks Roller Machine Moulding Roller: Mastering the Art

- Navigating the World of Glass Impact Testing Device Manufacturers

- What to Look for in a Softness Tester Manufacturer

- Medical Ultrasound Detection: Enhancing Diagnostics in Healthcare

- Unveiling the Power of High Strength Bending Straps

- Visit the World of Vibration Test Machines