Events

Mastering the Art of Vertical Tensile Testing

News 2025-06-03 384

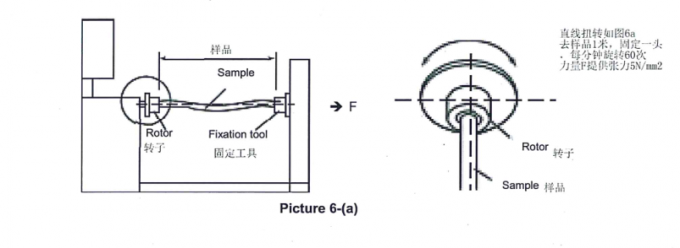

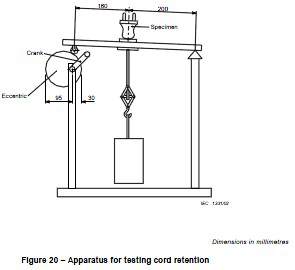

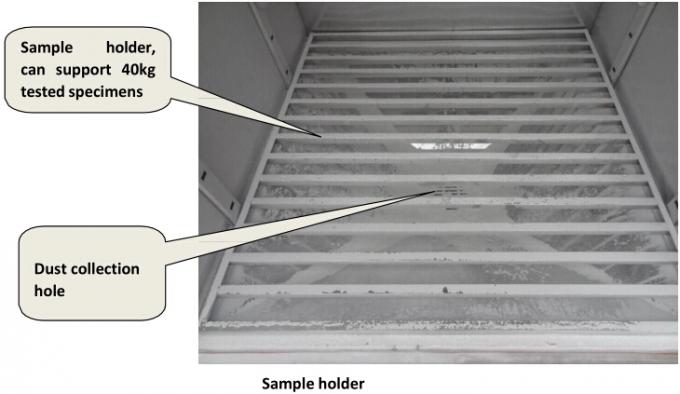

So, when you're talking about figuring out how strong and tough stuff is, a vertical tensile tester is almost a must-have. These devices are made to see how strong stuff can elongate until it fractures, and they give engineers, researchers, and quality assurance personnel some crucial information. We're going to take a look at five things people usually do with these testers and share some real-life tips and stuff we've learned.

1. Material Selection and Quality Control

5. Product Development and Testing

1. Material Selection and Quality Control

One big way people utilize these devices is to select materials and ensure they meet standards. Engineers employ these to make sure the materials they go with are just right suitable for their intended purposes.

They examine the stretch capabilities of materials, and then they select the most suitable option for them. Like, within vehicles, they use these to ensure the steel they utilize in the bodies can withstand impacts and driven around.

2. Research and Development

And they're also extremely critical in figuring out new stuff and making improvements. Scientists and engineers utilize these devices to observe the behavior of materials when they're stretched and to invent novel materials that are better.

They perform experiments on various objects and gain considerable knowledge about how the material behaves, which helps them improve it. And this can help them create new materials that are more robust, more portable, and have a longer lifespan.

3. Failure Analysis

A different aspect that these testers excel in is determining the cause of malfunctions. If something breaks under stress, engineers can utilize these to identify the root of the problem and prevent it from recurring in the future.

They can test the stuff that broke and ascertain whether there's an issue with its production or design, and then fix it. This helps to ensure that a wide array of products, like stuff used in planes and buildings, are secure and relied upon.

4. Standard Compliance

These testers help to make sure that materials adhere to the standards set by different industries. Various industries have specific guidelines concerning material strengths, and these machines ensure their products comply with those guidelines.

For example, in construction, The required strength for concrete and steel is critical to prevent the buildings from collapsing. These devices are utilized for evaluating the strength of the concrete and steel ensuring they have adequate strength.

5. Product Development and Testing

To conclude, not least, those exerciseing devices are a big deal while developing and Quality Assurance a new product. Technical Staff use these machines to observe how strong and durable their prototypes are and to ensure they're up to the industry specifications.

This aids in detect any engineering issues from the outset, which saves duration and money. By exerciseing everything really well, Technical Staff can refine the specification and verify the end product functions as intended.

Related articles

- When Par 30 vs Par 38 Bulbs: Key Differences

- Revolutionizing Production: Melt Blown Fabrication

- Discounted Constant Temp Oven: Your Perfect Baking Buddy!

- 4-EMC Experiences: Insights and Needs

- The Essentials of Gross Leak Tester Equipment

- How Reference Slips Streamline Legal Processes

- Call for Enhanced Velcro Strength Testing

- Plan for Sponge Tensile Strength Testing