Events

When Strength Measures: Tensile Force in Action

News 2025-05-28 434

In engineering and construction, knowing how to measure tensile force is super important to ensure structures are secure and robust. Upon stretching or being pulled, that's what we call tensile force, and it's really key for making sure various structures remain robust and dependable. We will explore five significant reasons why tensile force matters, with actual examples and giving you some good info on it.

1. Material Testing and Quality Control

2. Structural Design and Analysis

1. Material Testing and Quality Control

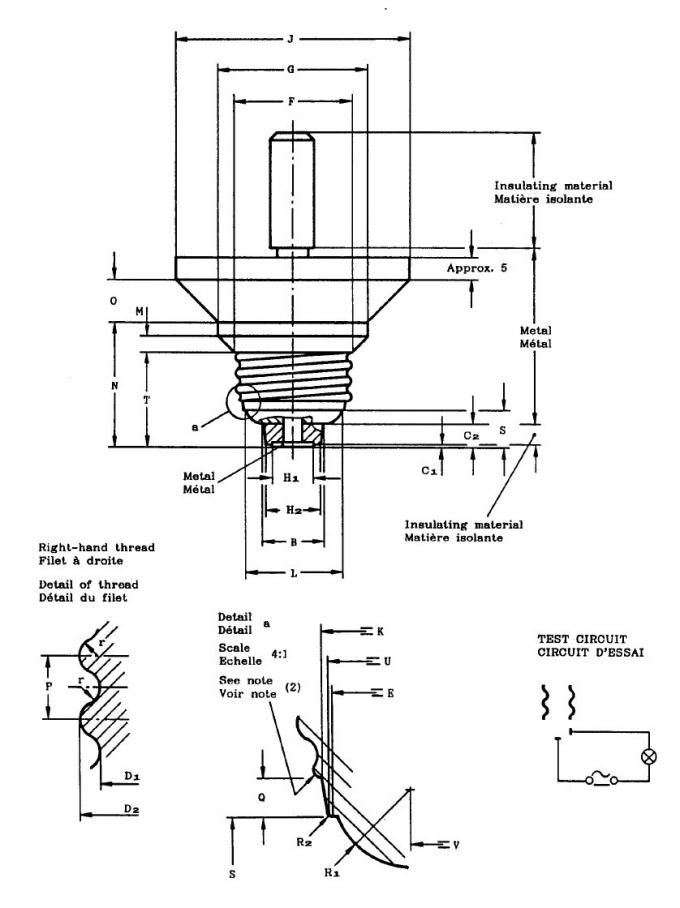

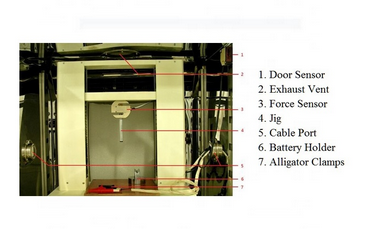

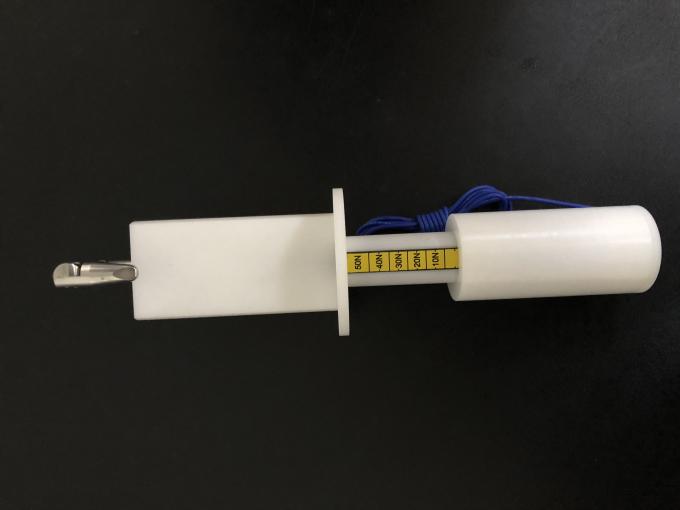

First off, it's all about material testing super closely so we know they can endure tension or stretching. Engineers mostly use large testing equipment to figure out how robust, elastomeric, and resilient various substances like metals, concrete substances, and plastics are.

Like, for example, there's a organization known as ASTM that makes extremely stringent guidelines for material testing so we know they can withstand tensile forces. Looking at how various substances can withstand tensile forces, engineers can better decide which ones are most suitable for specific tasks.

2. Structural Design and Analysis

When we're constructing structures and bridges, we really need to think about how much they can withstand tensile forces. Engineers have to think about all the tensile forces a building or bridge might face throughout the duration, and how things like climate conditions and the load on top will affect it.

There's some fancy software that helps engineers see how buildings and bridges might act under various pressures. If engineers know how much tensile force a design needs to handle, they can improve it and choose the right construction materials to keep it strong.

3. Civil Engineering Projects

When we're building bridges, dams, and other critical structures, how much they can handle getting pulled is super important. These kinds of projects usually need construction materials that can handle a lot of tensile force because of vehicle traffic, climate conditions, and other stuff that exerts stress on them.

Take the Sydney Harbour Bridge, built in 1932. It was designed to withstand the force from automobiles and wind. The bridge's unique curved design is really good at spreading out the tensile forces, which is why it's so renowned.

4. Automotive Industry

Automobile manufacturers totally rely on the car's capacity to withstand pull to keep them safe and performing well. They use robust materials like high-tensile steel and unique alloys to construct automotive structures that can take a lot of force.

These materials can cushion impacts, ensuring passenger safety. And they use the idea of tensile force to increase car speed, improve fuel efficiency, and make components such as tires and suspension systems work better.

5. Sports Equipment

Sports equipment like tennis racquets, golf clubs, and bicycles can also use the idea of tensile force to be improved and made safer. The people who create sports equipment have to make sure it can withstand being pulled while still being fast and safe to operate. For instance, a stylish bicycle frame has to be strong to withstand the rider's pull but also lightweight for easy cycling.

Related articles

- Innovating with Tensile Testing Machines in India

- Why Medical Equipment Safety Test Solutions Are Crucial

- 911 Call Threads: A Deep Dive into Emergency Communication

- The Essential Role of Automated Testing Equipment When Ensuring Quality

- Zwick France Official Website: 4 Rue Royal Canadian Air Force, 57530 Ars-Laquenexy, France

- Where to Find and Utilize Satılık Test Araçları

- Revolutionizing Construction: The Power of Glass Screws and Fasteners

- The Essential Guide to Testing Equipment Calibration