Torque Wrench Type Lubricating Oil Test Machine Accurate Display Of Force Value

Torque Wrench Type Lubricating Oil Test Machine Accurate Display Of Force Value

- Model:

Torque Wrench Type Lubricating Oil Test Machine Accurate Display Of Force Value

Torque Wrench Type Lubricating Oil Test Machine Accurate Display Of Force Value

Purpose: It is used to test the lubricating oil and anti-wear additives, grease, cutting fluid after mixing lubrication, anti-wear properties.

Feature :

1. Motor 300W , All aluminum export manufacturers specially customized (shape, material, frequency, speed), no heating, long motor life. Lock test motor does not burn, permanent not bad.

2. High precision processing technology, special processing methods, bearings, all adopt special customized bearings, to ensure that the machine does not beat, guarantee accuracy and life, to ensure the smooth operation of the machine.

3. Shell with thick steel plate and inner casing treatment, all-round no dead angle welding, chassis increased, the test force and then large as well as Taishan, 10mm steel plate solid stability to ensure greater pressure to withstand deformation

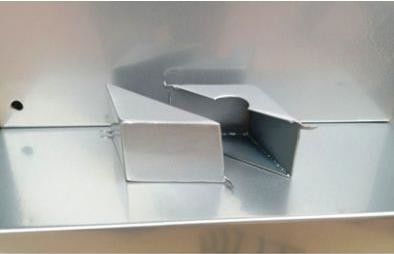

4. Lever is the line cutting process, precision without gaps, no abnormal sound test, no friction, no vibration, so that the experimental results more accurate, with particular attention to this model of the lever and the machine is one, is fixed in the shaft, so as not to leverage when in any of the force loading test jitter and skew, ensure the experimental results are accurate

5. The outer shaft design of grinding mill is divided into 3 parts. After a large number of experiments, the size is obtained. It can guarantee the longer life of the grinding sleeve, and also ensure the test results of the lubricating oil in the experiment process

6. Belt protection box, any leakage power cord must have a protective cover

7. Digital ammeter, because the voltage and current are not the same, but the high or low voltage influence, so we must master the voltage and current, to ensure the accuracy of the experiment

8. The oil cup was also redesigned to ensure adequate mixing test of lubricating oil, the protection of hand safety, and size according to the customer's needs change, can be customized

Parameter :

| Type | HJ0701 |

| Size | 390*190*160mm |

| Weight | 23kg |

| Function | Test the performance of lubricating oils and additives |

| Locking with no lubricating oil | 35nm (torque) |

| Locking with ordinary lubricating oil | 40nm (torque) |

| Locking with antiwear lubricating oil | 100nm above (torque) |

| Accuracy | 0.005mm |

| Voltage | 110v/220v 50hz/60hz |

| Torque wrench range | 0-300nm(torque) |

| Accuracy | 0.005mm |

| Parts | Steel ballX50 Power cordX1 Grinding sleeve (timken standard)X4 Oilstone X2 |

Operation step:

1. Turn on the power and start the motor. Use the oil stone to lubricate the shaft sleeve thoroughly with the ordinary lubricating oil. When grinding, press the whetstone evenly with your thumb, rub the shaft sleeve after grinding, and turn off the motor. The purpose of grinding is to eliminate the effect of the original oil film or nano film on the experimental results.

2. Fix the steel ball in the short lever trough of the test machine, add the common lubricating oil in the oil box, and install the lubricating oil box, short lever and torque wrench

3. Start the motor and run first. And then slowly evenly to the wrench wrench (this process must be slowly evenly, this process is like adding weight), see the ammeter pointer changes, the pointer increases, prove that power consumption increased, consumption Electricity is fueled. After the process of increasing the noise gradually increased, continue to force until the wheel stopped, the machine locked, quickly turn off the power. Write down the torque wrench readings at this time, remove the short lever, observe the grinding wheel grinding wear depth, wear marks area.

4. Grinding shaft sleeve again, because the experiment has been worn on the axle sleeve, so it should be polished. (make sure that every oil is polished before it is done, and that the experiment is fair, and that grinding is the key to the whole experiment, and it is very important)

5. Add lubricating oil in the oil box

6. Repeat step 3

7. Remove the oil box. In the absence of oil, the machine can add to the force as it does with anti-wear oil, indicating that the nano film does exist and turn off the machine switch. Then compare the changes of the ball marks.

Attention :The sleeve must be polished clean with oi stone when change oil each time, if not clean grinding machine will be accompanied by the noise and jitter, affect the experimental results it is crucial to the success of the experiment!