Plug Cord Compression Testing Machine Flexing Test Swivel Machine IEC60884-1 Figure 21

Plug Cord Compression Testing Machine Flexing Test Swivel Machine IEC60884-1 Figure 21

- Model:

Plug Cord Compression Testing Machine Flexing Test Swivel Machine IEC60884-1 Figure 21

Flexing Test Swivel Machine , Plug Cord Flexibility Tester IEC60884-1 Figure 21

Product details:

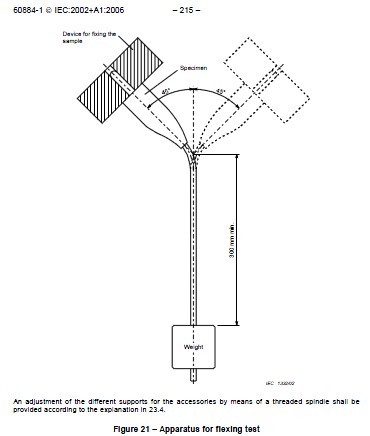

The FL-1 Plug Cord Flexibility Tester is designed and manufactured according to the standard requirement of IEC 60884-1 figure 21 which calls for 10,000 flexing at a rate of 60 flexing per minute. Six cables or cords fitted with plugs can be tested simultaneously. The cables are connected to a socket and the tail of the cable is connected to the tester to detect if an internal fault occurs with the cable wiring or accessory connection. The instrument starts in a vertical orientation and then flexes the specimens 45° on either side of the vertical for a total 90° of flexing. A standard rate of 60 flexing per minute is used but a slower rate can be selected if desired.

A set of customer selected weights are included with the instrument so that the proper force can be applied to the cable during the test.

Power Supply | 220V 50Hz or 115V 60Hz |

Number of Flex Per Test | 1-999999 (selectable) |

Number of Test Station | 6, with 6 sets of clamp device |

Rate of Flexing | 10~60 times/min(selectable) individual counts for each station |

Flexing Angle | Swivel angle on either side for 45° , 60°, or 90°(or 180°)(selectable) |

Weight | 10N/20N*6(the weight of UL113g and 284g can be customized) |

Dimensions | W*L*H=500mm *1000mm* 1100mm |

Conforms to standard | IEC884-1 Figure 21 and clause 23.4,IEC320-1,VDE0620 |

Mechanical theory | The crank block on the reduction gearbox is driven by the electric motor to do the reciprocating action. |

Using method:

Set up the testing sample on the swing fixture and conduct the circuit. In the other side, the according weight is used, then set the flexing angle and testing times as well as the required speed. Then start the equipment. When the sample is broken off, the corresponding counter stops working and the indicator light off. At that time, the counter displayed is the testing times of the samples. When the total testing times are reached, the equipment will stop working.

This testing machine can be connected with Load of power line tester for the load test.

About us :

KingPo Electromechanical Co., Ltd is a leading company in inspection equipment industry, established in 2003 and located in Guangdong, China. Our company introduced advanced equipment, combined with the most advanced technology production processes, strict quality control system to control the entire process of production. The company combined with a number of high-tech management personnel and advanced equipment, and together with the modern management, computer design and control, our products has reached the international advanced level. The company set R&D design, production, sales as one, specializing in producing electric wire inspection equipment of plug and socket, mechanical robustness testing equipment of electronics, inspection equipment of electronics’ on-fire danger, testing indicator of anti-electric shock and solid objects' entry, general inspection equipment, and other non-standard testing equipment. Our products enhance good selling at home and abroad, and have established supply relationships with a number of well-known companies.