PLC Control IEC Test Equipment for Circular Saw Switch And Lower Guard Integrated Test

PLC Control IEC Test Equipment for Circular Saw Switch And Lower Guard Integrated Test

- Model:

PLC Control IEC Test Equipment for Circular Saw Switch And Lower Guard Integrated Test

Circular Saw Switch Endurance And Lower Guard Recovery Time Integrated Test Device CSG-2

Standard: EN 60745-2-5: 2010 Annex M21.18, Annex M21.18.301, Annex M21.203, Annex M21.301, figure M.301, IEC60745-2-5:2003 Annex BB.20.102, EN 60745-2-5:2010 clause 17.101 and clause 19.102.3.

Application: It is used to test the circular saw switch performance and circular saw lower guard’s durability and recovery time.

Test sample: Circular saws

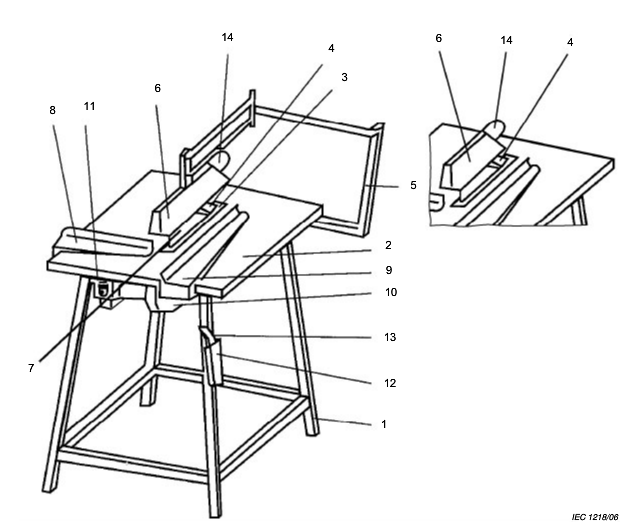

Feature: This equipment is composed of two parts, the mechanical system and electrical control system.

Mechanical system is the table for circular saw. There are a switch and sample socket on the table, operator can push the switch to turn on or off the load power supply to the test sample; different sizes of circular saws can be placed and fixed on the table; on the table, device for locking the switch of the hand-held circular saw in the “on” position; the blade can extend to the bottom of the table through the middle groove; on the table where under the blade, there are a the lower guard putter and two position sensors , which can be drive the lower guard of the circular saw to be opened or closed.

The electrical control system consists of the load power supply, MITSUBISHI PLC, 7 Inch Touch screen and etc. Can achieve manual operation and automatic operation.

Manual control:

The operator can manually move the lower guard putter by press “Manually Rotate Clockwise” or “Manually Rotate Counterclockwise” on touch screen, then the lower guard gradually open or close, when the putter makes the lower guard to be opened to the maximum open position (corresponding position sensor indicator is lighting), at this time, operator can stop the lower guard opening action; and operator can manually make the circular saw switch to be ON or OFF by pressing “Switch On Manually” or “Switch Off Manually” on the touch screen, the switch locking device can automatically lock or release the switch of the circular saw. Operator can press the Stop button on the panel to achieve to supply or not supply load voltage to the test sample.

Automatic operation:

1. Operator can pre-set the interval time of the locking device lock or release the circular saw switch, the interval time of the load voltage supplied to the test sample, and the opening residence time of the lower guard of the circular saw, after that, operator only press “Start” on touch screen, the above testing for the circular saw switch will be processed automatically.

2. The following is mainly for the circular saw lower guard’s durability and recovery time test : The saw is to be set for a 90°cut and oriented in the horizontal plane. The lower guard is to be cycled from the full closed position to the maximum open position and then released for 50 000 cycles at a rate not less than 10 cycles per minute, the number of times is recorded by the position sensor. The close time of the lower guard is not less than 0.3s, if exceed 0.3s, then the number of a timeout is counted. The close time of the lower guard of the last time is recorded after the equipment runs to the required test times, and the equipment will automatically stop.

Technical Parameters

| No.: | Serial No.: | Parameter | Remark |

| 1 | Input Power | 220V/50Hz | |

| 2 | Control System | Mitsubishi PLC, 7-inch touch screen | |

| 3 | Station | One | |

| 4 | Built-in Load | 0~250V/5KW voltage regulator, equipped with B socket | |

| 5 | Test Cycles | 0-999999, can be preset | |

| 6 | Test Speed | ≥10 freq/min | |

| 7 | Guard Recovery Detection Time | 0.01-9.99s, can be displayed | Recovery time |

| 8 | Circular Saw Switch Locking Device | Lock or release the switch by motor driving | |

| 9 | Operation Buttons | Stop and Start buttons on the panel for operator easily cut off or turn on the power |

IEC Test Equipment

IEC Test Equipment

IEC Test Equipment