IEC60884-1 Figure 11 Test Apparatus For Checking Damage To Conductors Test Machine

IEC60884-1 Figure 11 Test Apparatus For Checking Damage To Conductors Test Machine

- Model:

IEC60884-1 Figure 11 Test Apparatus For Checking Damage To Conductors Test Machine

IEC60884-1 Figure 11 Test Apparatus For Checking Damage To Conductors Test Machine

Product details:

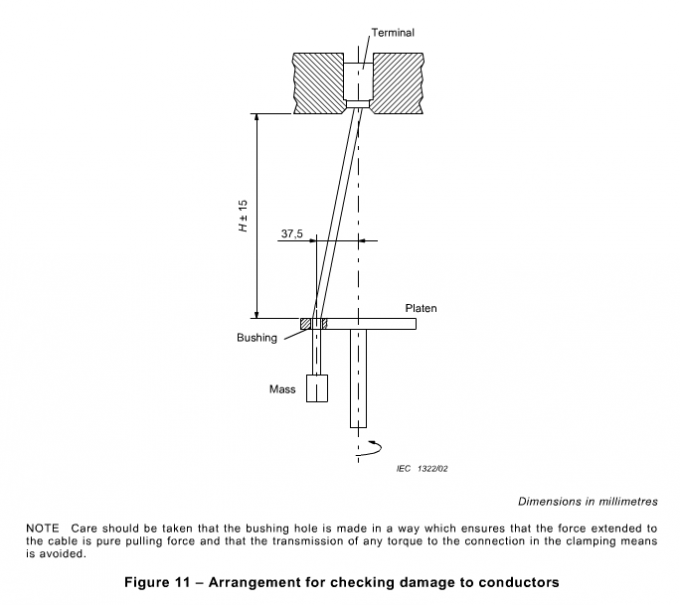

This testing machine is also called the test apparatus for checking damage degree of wire which confirms to many standards such as IEC60884-1 clause 12.3.10 figure 11, IEC60669 and so on. This compliance is used for judging whether the design and the structure of the clamping screw terminal is correspondent with the requirement of non over-damage to the wire. Besides, it is also used to check whether the clamping screw terminal can bear the stress during the process of normal usage. The testing times can be preset before the test, and the compliance stops automatically with the alarm when the testing times are reached.

Technical parameters:

Item | Parameters |

Power Supply | AC220V, 50Hz |

Test Speed | (10±2)r/min |

Timer Range | 0-99 hours 59 minutes |

Working Stations | 2 working stations |

Test Height | 260, 280, 300, 320mm (Adjustable) |

Rotating Radius | 35mm |

Rotating Weight | 0.3,0.4,0.7,0.9,1.4,2.0kg, each for 2 pieces |

Pulling Weight | 30N, 40N, 50N, 60N each for 2 pieces |

Bushing Hole Diameter | Φ6.5mm, Φ9.5mm, Φ13mm, Φ14.5mm, each for 2 pieces.

|

Dimensions | 1110mmX405mmX1320mm. |

Environmental Requirements | 0 ~ 40℃, Relative humidity ≤80%. |

Values for flexing under mechanical load test for copper conductors

Nominal cross-sectional area of conductor (mm²) | Diameter of bushing hole ( mm) | Height (mm) | Mass for conductor (kg) |

0.5 | 6.5 | 260 | 0.3 |

0.75 | 6.5 | 260 | 0.4 |

1.0 | 6.5 | 260 | 0.4 |

1.5 | 6.5 | 260 | 0.4 |

2.5 | 9.5 | 280 | 0.7 |

4.0 | 9.5 | 280 | 0.9 |

6.0 | 9.5 | 280 | 1.4 |

10.0 | 9.5 | 280 | 2.0 |

16.0 | 13.0 | 300 | 2.9 |

25.0 | 13.0 | 300 | 4.5 |

35 | 14.5 | 320 | 6.8 |

| |||

1. Bushing and weight should be kept clean and dry in non-working time, if necessary, painted with oil and seal.

2. The bearing parts should be lubricated periodically, and the whole unit should be kept clean.

3. Pay attention to safety when carrying the heavy weights.

IEC Test Equipment

IEC Test Equipment

IEC Test Equipment