Clause 13.4 Tracking Test Equipment Determination Of The Relative Resistance To Tracking Performance

Clause 13.4 Tracking Test Equipment Determination Of The Relative Resistance To Tracking Performance

- Model:

Clause 13.4 Tracking Test Equipment Determination Of The Relative Resistance To Tracking Performance

IEC 60065:2014 clause 13.4 Tracking Test Equipment

Standard:

Conforms to IEC 60065:2014 clause 13.4, IEC60335-1 clause 29.2, Annex N

Application:

It is used for determination of the relative resistance to tracking performance that solid electrical insulating material under the action of an electric field, when the surface exposed to water containing impurities.

Test sample:

Lighting equipment, low-voltage electrical appliances, household electrical appliances, machine tools, electrical appliances, electric motors, electric tools, electronic instruments, electrical instruments, information technology equipment, insulation materials, engineering plastics, electrical connectors, accessories industry.

Feature:

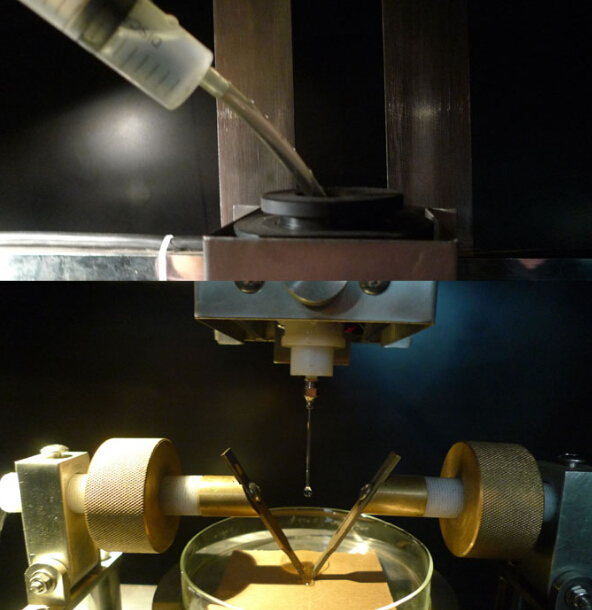

The working principle of the leakage tracking test(tracking index testing) is that the conducting liquid (0.1%NH 4 CL) of required volume in the required height (35mm ) and required time (30s) drops with the voltage between the platinum electrodes (2mm× 5mm )on the surface of solid insulating material. Thus the users evaluate the tracking resistance performance of solid insulating material surface under the combined influence of electric field and humid or contaminate medium. In a word, this device is used to measure the compare tracking index (CT1) and electrical resistance index (PT1).

Parameters:

| Timing device | 9999X0.1S Resolution | Drip interval | Adjustable | |

| Electrode material | Platinum | The height of the drip | 30~40mm | |

| Electrode specifications | 5mm*2mm | Drip delay | 0.2S (solenoid valve open time) | |

| Electrode spacing | 4±0.1mm | Drip size | 45 ~ 50 drops / cm3 | |

| Electrode pressure | 1±0.05 N | Delay electric circuit | 2 ± 0.1S (at 0.5A) | |

| Electrode angle | 60° | Test voltage range | 0~600V 1.5% | |

| Short circuit voltage drop | 8% MAX | Electrical parameters | 1.5KW/127VAC/60Hz | |

| Short-circuit current | 1±0.1A 1% | Working volume | > 0.5 M³(0.1 M³by option) | |

| Environmental requirements | 0 ~ 40 ℃ / ≤ 80% relative humidity | |||

| Standards | GB4207, GB4706, IEC60695, IEC60112, UL746A, ASTMD3638. | |||

Picture for reference: