220V 50Hz Flammability Testing Equipment / Glow Wire Test Apparatus

220V 50Hz Flammability Testing Equipment / Glow Wire Test Apparatus

- Model:

220V 50Hz Flammability Testing Equipment / Glow Wire Test Apparatus

PLC Control Glow Wire Test Apparatus Touch Screen Operation IEC60695 Flammability Test Equipment

Products Introduction

This device is manufactured according to the standard of IEC60695-2-10, IEC60695-2-13. It also conforms to the standard requirement of UL746A. This device simulates the thermal stress test of glowing component or heat source like overload resistance or ignition source which is caused in a short time. It is suitable for electric and electronic products, household appliances and other material to do fire hazard testing. It is also used in the no flame ignition source fire test to test initiation temperature and flammability index of related glowing filament.

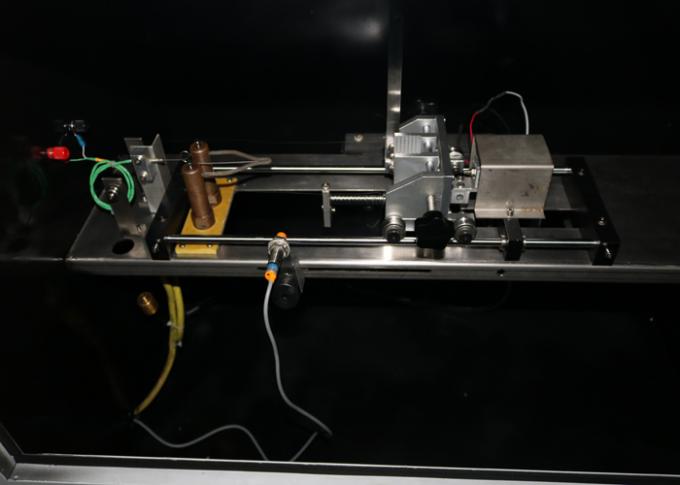

This equipment adopts a new design concept, while in the realization of accurate positioning, but also to achieve the rapid adjustment after replacing the sample, truly meet the requirement of easy and convenient operation; The control system adopts PLC and touch screen control, each parameter can reflect the real situation of the relevant parameters more timely and accurately, and the operation is intuitive and convenient, so as to meet the needs of scientific research.

Technical Parameters

| ParametersModel | GW-2(Touch screen) |

| Working voltage | 220V /50Hz |

| Control operation mode | PLC control, 7 inch color touch screen operation, with infrared remote control |

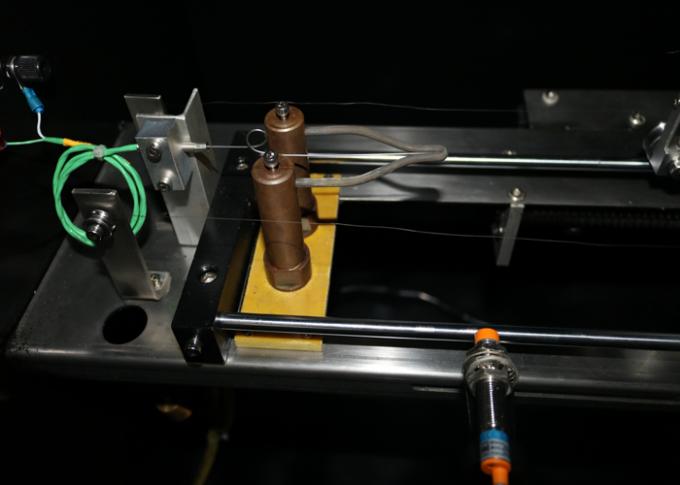

| Glowing filament | Ф4mm ± 0.04mm (> 77 % Ni/20 ± 1 % Cr) special standard ring shape,horizontal standing |

| Specimen pressure on glowing filament | 0.95N±0.1N |

| Maximum depth of heating | 7mm ± 0.5mm |

| Specimen movement speed | 10mm /s ~ 25mm /s |

| Temperature calibration | Calibration temperature:960°±10°C, the hot wire by electric heating |

| Thermocouple: RS imported 1mm armour nickel-chromium/nickel/ nickel aluminum K-Thermocouple, temperature resistance 1100° | |

| Silver foil: purity 99.8%, area :2m², thickness:0.06mm | |

| Tray | A layer of silk paper (12~30g/m³) is covered on the 10mm thick pine board, with a distance of 200±5mm below the test sample |

| Test chamber | >0.5 cube,sample distance from the inside of the box is greater than 100mm, black yogon background,background illuminance ≤ 20Lx,with exhaust fan |

| Testing time | 30s±1s |

| Test procedure | The test sample is driven by the car and automatic run, the car will return automatically after glow-wire entered the test sample of 7mm |

| Lighting | Equip with lighting in the test chamber, with control |

| Dimension | 1100*550*1200mm, 140kg |

Preparation Before Test

The specimen is installed on the fixture, to make the glow wire tip is pointed to the specimen’s center

Place the specified layer below the test specimen.

Press【Forward】button, when the test specimen is in contact with the glow wire, press【Stop】button immediately.

Adjust the position of the automatic timing: slowly adjust the proximity switch to move it to the fixture, when proximity switch indicator light is bright, at this time, this position is where the test specimen just touches the glow wire tip, simultaneously timing begins automatically, then lock the screw of the proximity switch.

Press【Reset】button,make the fixture away from the glow wire.

Press【Forward】button, make sure the fixture stops automatically and timing begins when the sample touches the glow wire.

Press【Reset】, to make the fixture backward.

Notice

To prevent the electrical shock, scalding, burn or fire accident.

To prevent the inhalation of the toxic gas or smoke.

To prevent the damage of the toxic residual to the human health.

Over-temperature and low-temperature protection function. In case of higher than the maximum limit temperature, the heating is stopped; in case of lower than the lower limited temperature, the heating is started; in case of the heating time more than 5 minutes, the heating is stopped automatically.

During the test, the fan should be shut off so as not to affect the test result; after completing the test, turn on the fan

Flammability Testing Equipment

Flammability Testing Equipment

Flammability Testing Equipment