1KN ~ 20 KN Battery Test Chamber Crush Nail Penetration 0~400MM

1KN ~ 20 KN Battery Test Chamber Crush Nail Penetration 0~400MM

- Model:

1KN ~ 20 KN Battery Test Chamber Crush Nail Penetration 0~400MM

1KN ~ 20 KN PLC Control Battery Crush Nail Penetration 0~400MM Test Chamber

Production information :

This tester is designed and manufactured according to IEC62133 clause 7.3.6,8.3.5 IEC60086-4 clause 6.5.3 IEC 60086-1, GB/T 18332.2-2001, UL1612,UN38.3,GB/T 31241-2014 and so on .It is simulate the power lithium battery terminal actual using environments, such as battery in crush, penetration and feedback the various results in different crushing/penetration conditions.

Testing should be under environment temperature of 20℃ ± 5℃, put the battery which connect with thermocouple (the touch point of thermal couple fixed on battery large surface) in the draught cupboard, with 3mm non corrosion stainless nail penetrate the center point of the battery with speed of 20mm/s-80mm/s.

Parameters:

| Structure | Vertical type with vertical pressure structure |

| Input Voltage | 380V 50 Hz |

| Pressure Range | 1KN ~ 20KN(Controllable) |

| Force Tolerance | ±1% |

| Crush Range | 0~400MM |

| Unit Switch | Kg/N/Lb |

| Nail Penetration Speed Range | 1 ~ 80mm/s(Controllable) |

| Speed Accuracy | ±0.1MM/S |

| Nail Penetrate Power | Oil Pressure |

| Testing Space | ≥ W300*D300*H200mm |

| Overall Dimension | W940XD780XH1620 mm |

| Observation Window | 390 X 360mm(20mm thick tempered explosion-proof glass) |

| Lighting | With light on chamber inner top side |

| Base | Installed with 4 universal wheels and 4 fixing casters, available for free moving and fixing . |

| Explosion -proof Devices | With air release function, exhaust the waste air which produced when testing; With explosion proof and pressure release function,Magnetic adsorption type pressure relief door on back side of protection cabinet(300*300mm),when with strong air shock, the relief door open automatically ,reduce explosion shock force . |

| Chamber Bottom | With extract type collection device for electrolyte and Experimental debris. |

| Tungsten steel needle | Φ3X100MM 10 pieces Φ5X100MM 10pieces |

| Machine Weight | About 400KG |

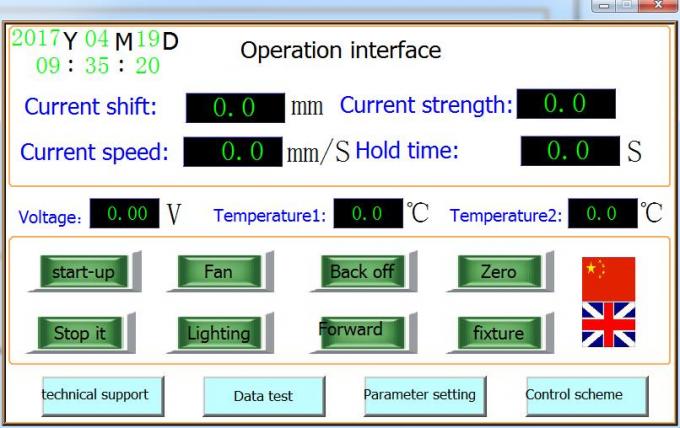

| Display Method | PLC Touch Screen |

Standard Description Of IEC62133

7.3.6 Crushing of cells

a) Requirements

Severe crushing of a cell (for example ,during disposal in a waste compactor )shall not cause fire or explosion .

b) Test

Each fully charged cell is crushed between two flat surface ,the force for the crushing is applied by a hydraulic ram exerting a force of 13KN+1 KN,the crushing is performed in a manner that will cause the most adverse result ,once the maximum force has been applied ,or an abrupt voltage drop of one -third of the original voltage has been obtained ,the force is released .

A cylindrical or prismatic cell is crushed with its longitudinal axis parallel to the flat surface of the crushing apparatus ,to best both wide and narrow sides of prismatic cells ,a second of cell is tested ,rotated 90 º around their longitudinal axes compared to the first set .

c) Acceptance criteria

No fire ,no explosion

8.3.5 crush (cells )

a) Requirements

Severe crushing of a cellshall not cause fire or explosion .

b) Test

each fully charged cell ,charged according to the second procedure at the upper limit charging temperature in 8.1.2,is immediately transferred and crushed between two flat surfaces in an ambient temperature ,the force for the crushing is applied by a hydraulic ram exerting a force of 13KN+1 KN.the crushing is performed in a manner that will cause the most adverse result .once the maximum force has been applied or an abrupt voltage drop of one -third of the original voltage has been obtain of 10% of deformation has occurred compared to the initial dimension ,the force is released (whichever condition occurs first should be the indication that the force should be released )

A cylindrical or prismatic cell is crushed with its longitudinal axis parallel to the flat surface of the crushing apparatus .test only the wide side of prismatic cells .

c) Acceptance criteria

No fire ,no explosion

Please click here Battery Test Equipment.pdf to get the whole sets of battery testing equipments.